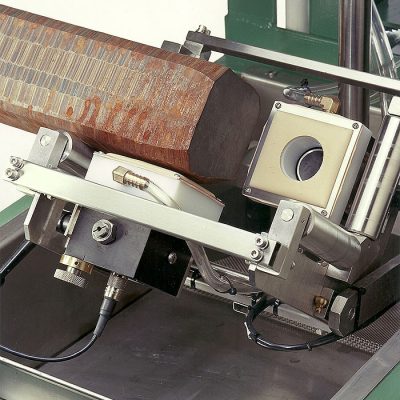

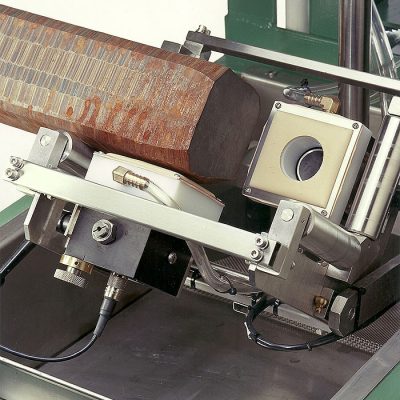

MAC has cost effective TacTic® “Spin-the-Tube” immersion tank ultrasonic systems which can be used to test tube up to 8” and bar up to 6” diameter, where high through-put speed is not a requirement. The systems locate internal and external defects and inconsistencies in the wall thickness of tubular products.

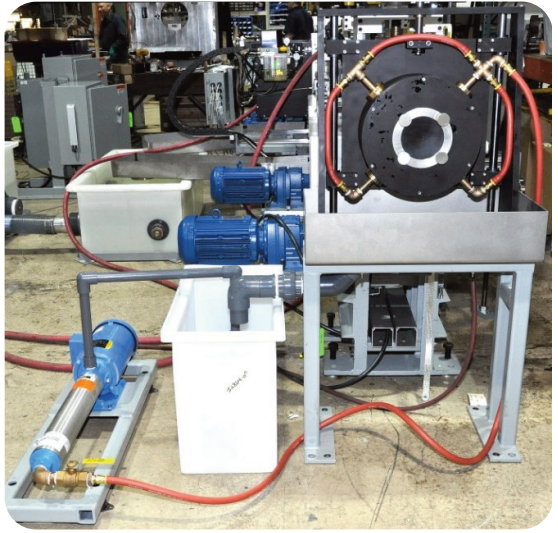

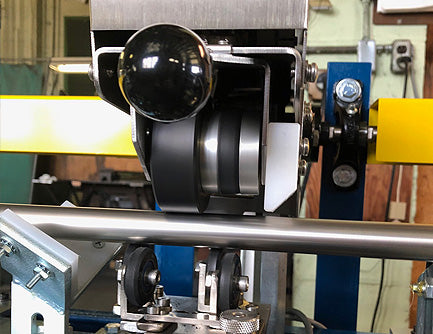

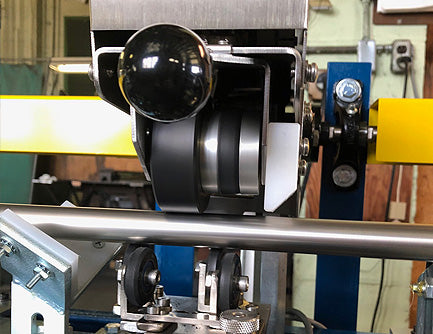

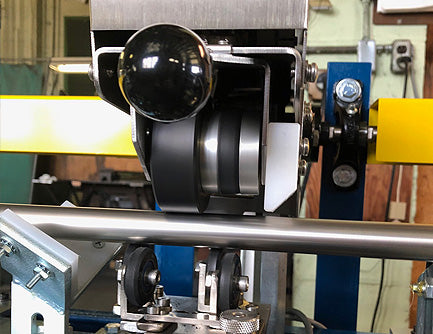

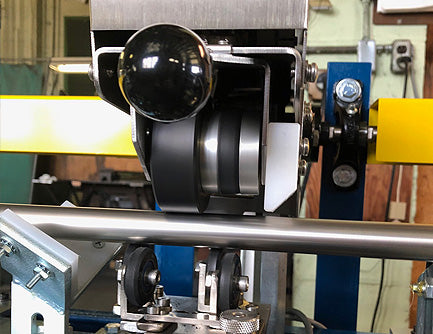

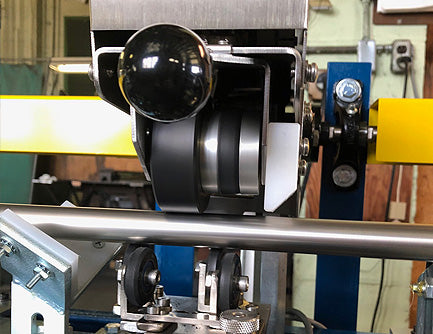

TacTic’s ultrasonic testers and idlers are specifically designed for the material you need to inspect, including round or flat material of varying sizes as well as tube or pipe welds. The tester and idler sections feed, rotate, and inspect the material.

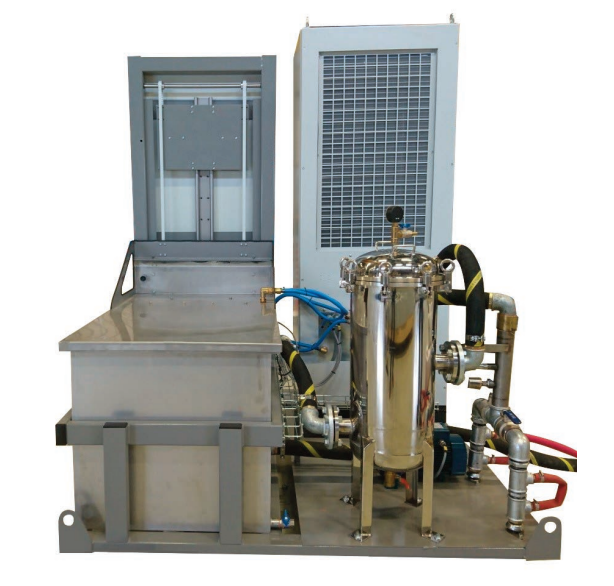

TacTic’s UT equipment models with immersion tanks work equally well for ultrasonic tube, pipe, and bar inspection in automated production use or in manual, laboratory-type applications. We also offer a wide variety of systems for flat material and tankless testing.

Model 77E can test squares, rectangles, hexagons and strip. The system features horizontal support rollers, vertical positioning rollers and fixed or “following” transducer positioners. The Model 77E is suitable for fast, accurate flaw detection in flat materials.

You may also like

For use with Magnetic Analysis Test Systems

Prevent False Test Signals from Contaminated Bar & Tube Surfaces & Reduce Rotary Cleaning Downtime.

Model 204 and 205 Series Air-actuated “Extended” Drive Units are overhead drive wheels.

Material is placed on forward-sloping, plastic-covered storage arms of the loader and is restrained from rolling off by means of adjustable stops at the front of the loader modules.

These sorters are available for manual or automatic operation. After material is inspected, it is unloaded and ready for sorting.

Model 150 Series Storage Rails are available for use adjacent to output Idler sections.

Models 187 and 188 Unloaders unload each piece after it has passed through the Tester to the output Idler Sections.

These rugged conveyor sections are placed at each end of a tester to provide good support for incoming and outgoing pieces.

“Heavy Duty” Testers are powered either by a 7.5 HP motor (76F) or by a 10 HP motor (76G).

Model 76E “Standard Duty” Testers feature tanks with an inside length from 6″ to 30″ (150-760 mm).

These testers use pneumatically raised transducer coupling shoes in one or more dual probe carriers that contact rotating material from underneath.

These testers are designed to handle material sizes ranging from 2 1/2 to 7 inches (63-178 mm).