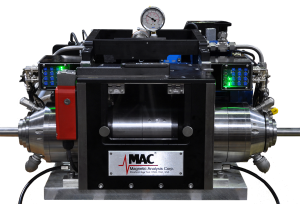

MAC offers Phased Array UT testing solutions in addition to single element technology to meet your specific needs.

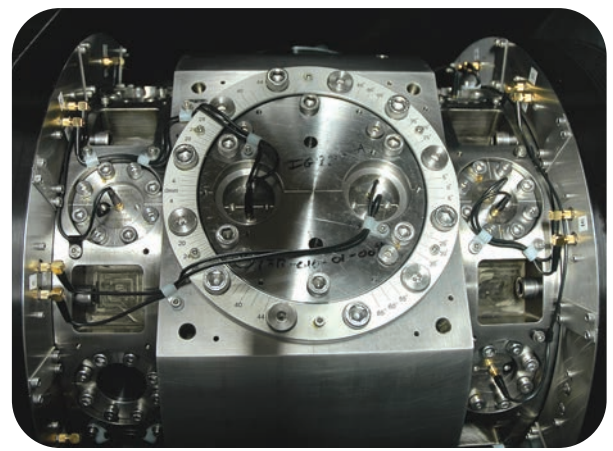

- Phased array ultrasonics uses multiple transducer elements, which can be pulsed independently, combined in one probe to create an electronically steered and focused beam that can be customized for a specific application. By varying the timing of the individual transducers, it allows precise control of the beam angle and focal distance to achieve superior results in testing.

- The phased array probe does not need to be physically moved because the angle and focus can be changed electronically with no physical change of the probe to adjust for different test product sizes and characteristics.

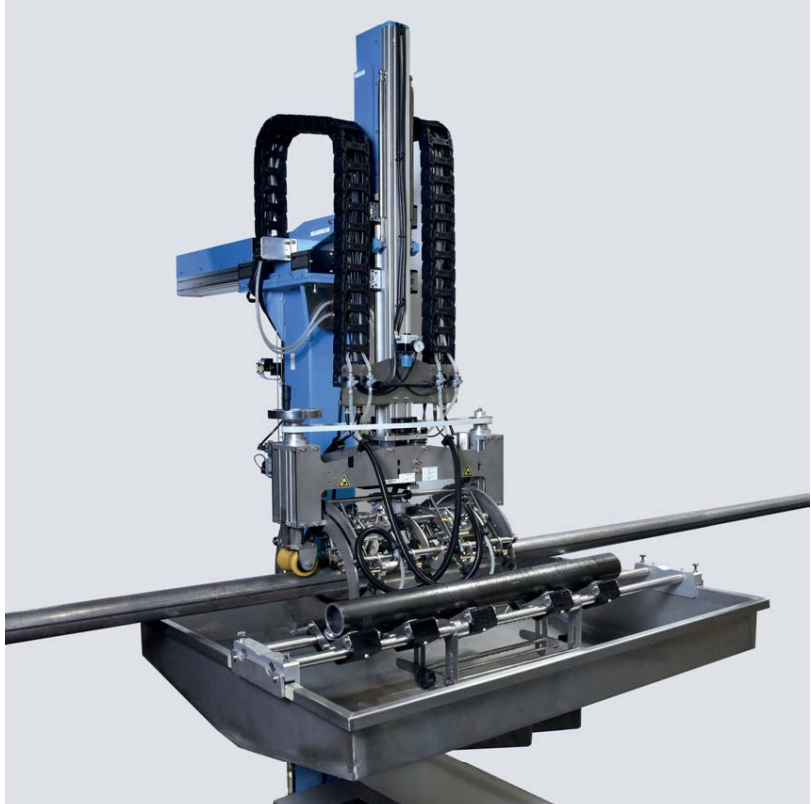

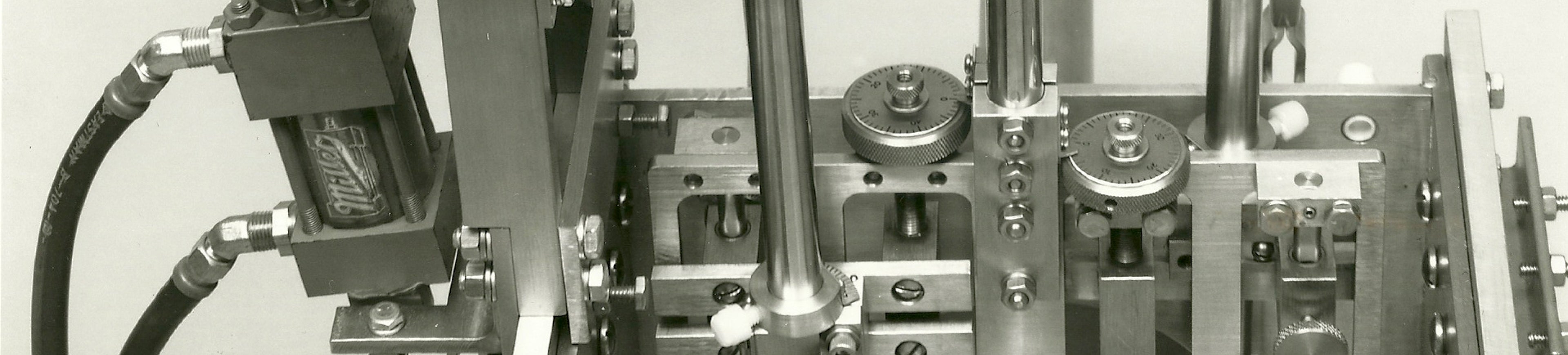

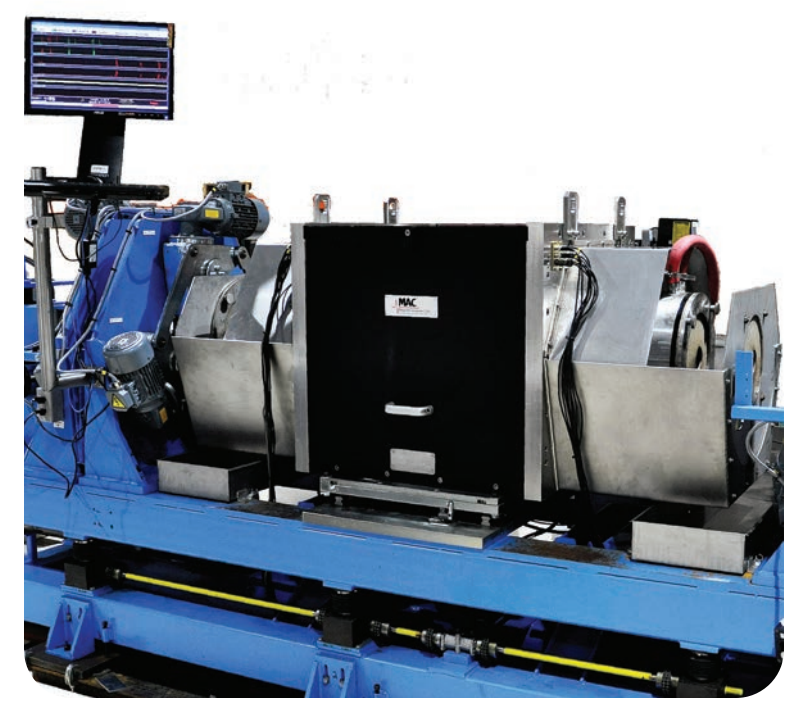

MAC now has TacTic™ ultrasonic test systems for testing tube and bar.

- These systems are especially well suited for metal manufacturers who produce small batches of material or require frequent diameter size changes.

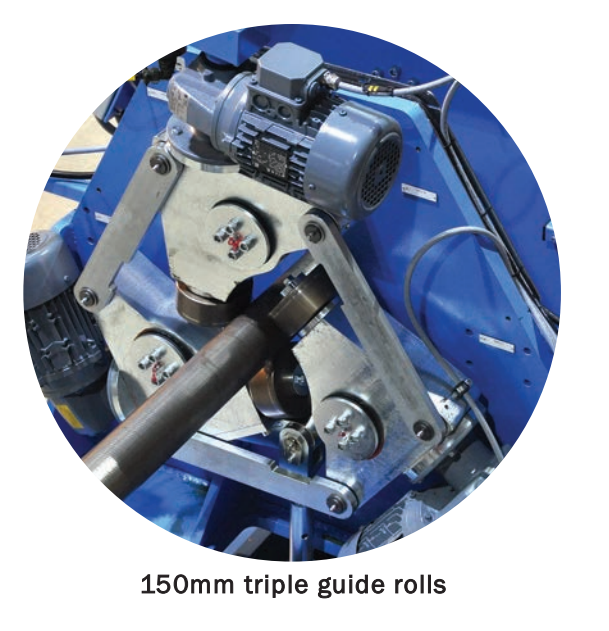

- Designed for specialized immersion tank “spin the tube” benches and mechanics.

- Cost-effective for lower through-put speed applications, including laboratories.

MAC Solutions:

- As the use of nodular graphite iron material has expanded in recent years for automotive safety parts, ultrasonic velocity measurement provides an industry accepted means of verifying the material integrity of the part. The Echomac® VM measures velocity to assess nodularity in ductile iron cast automotive components. It operates with either full immersion or bubbler couplant technology and can test two parts simultaneously in separate test situations.

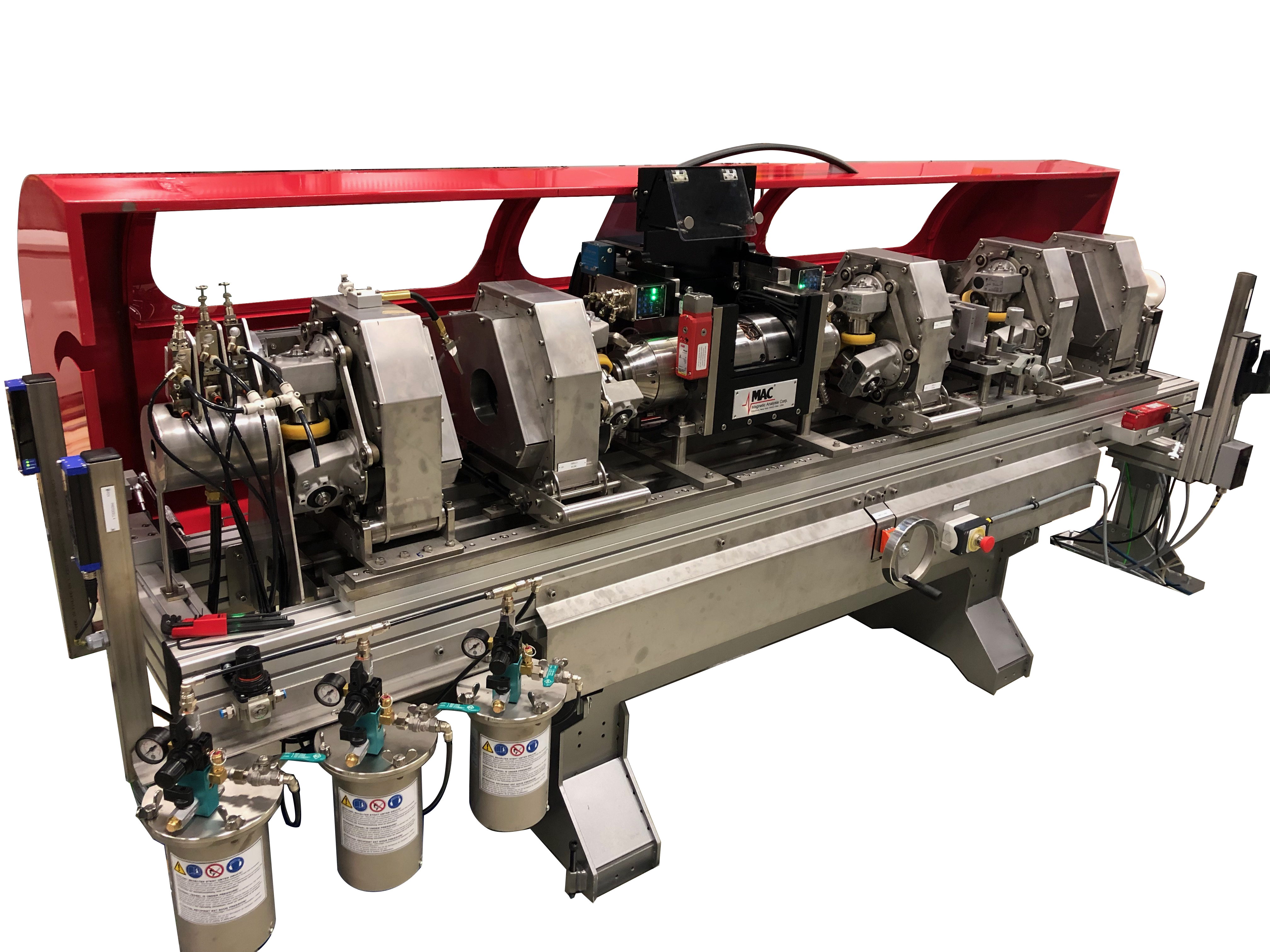

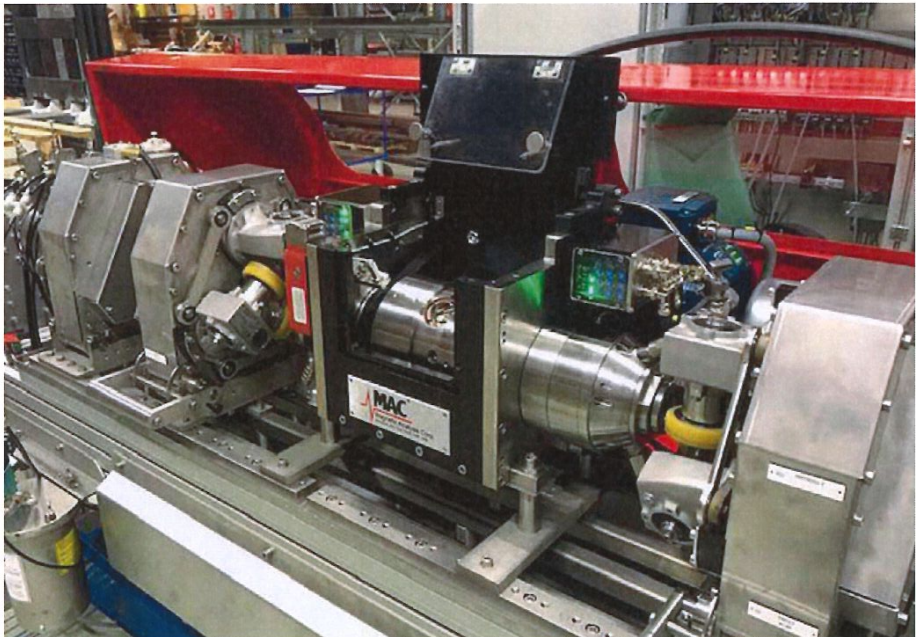

- The Echomac® Phased Array Test System offers high-speed parallel processing to handle a large amount of data and is designed for situations where phased array ultrasonic technology is preferred to conventional ultrasonics.

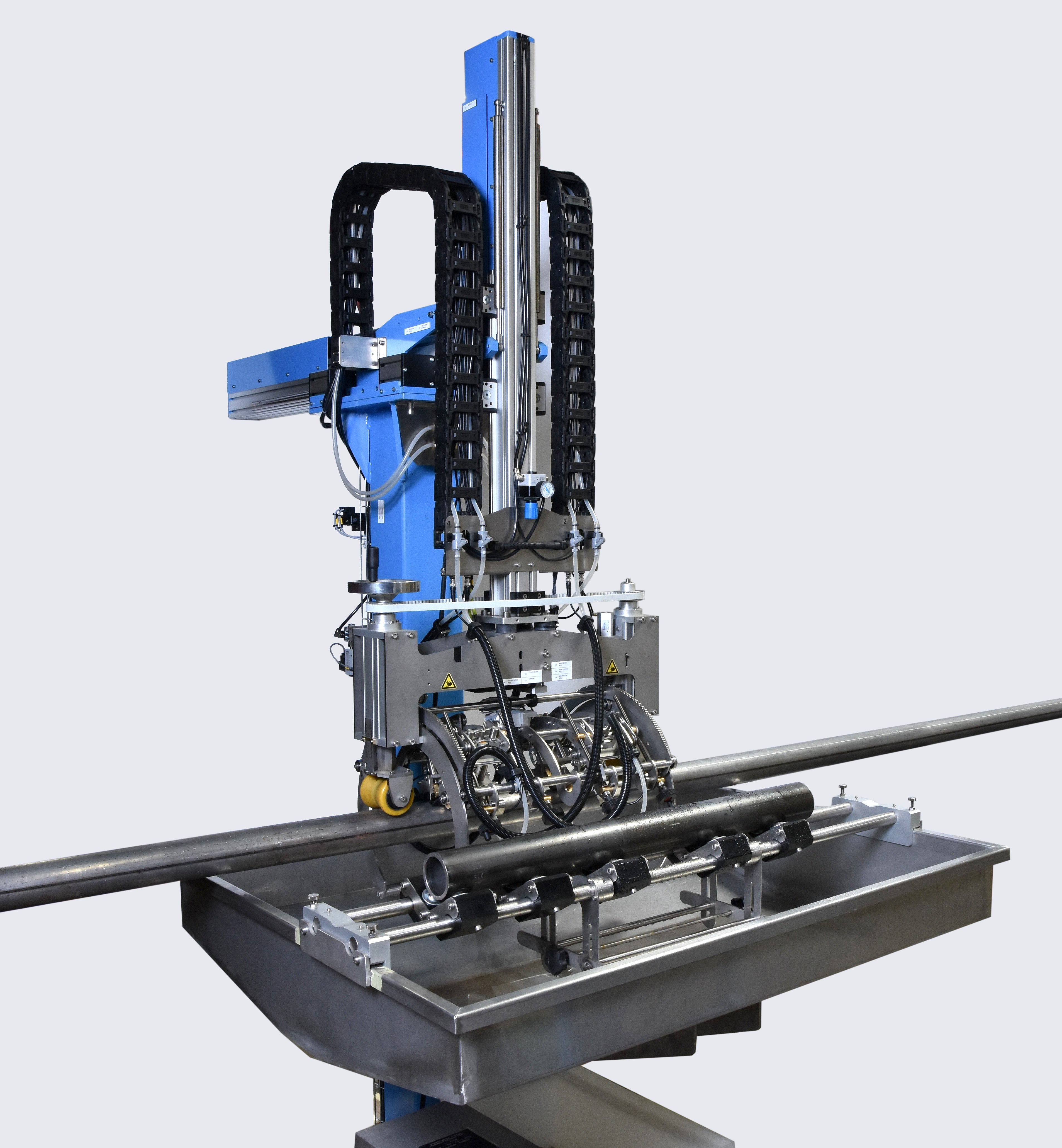

- The Echomac® PA BT Bar Tester includes a unique water box design which minimizes water loss and bubbles while ensuring that bars are properly centered relative to the transducers.

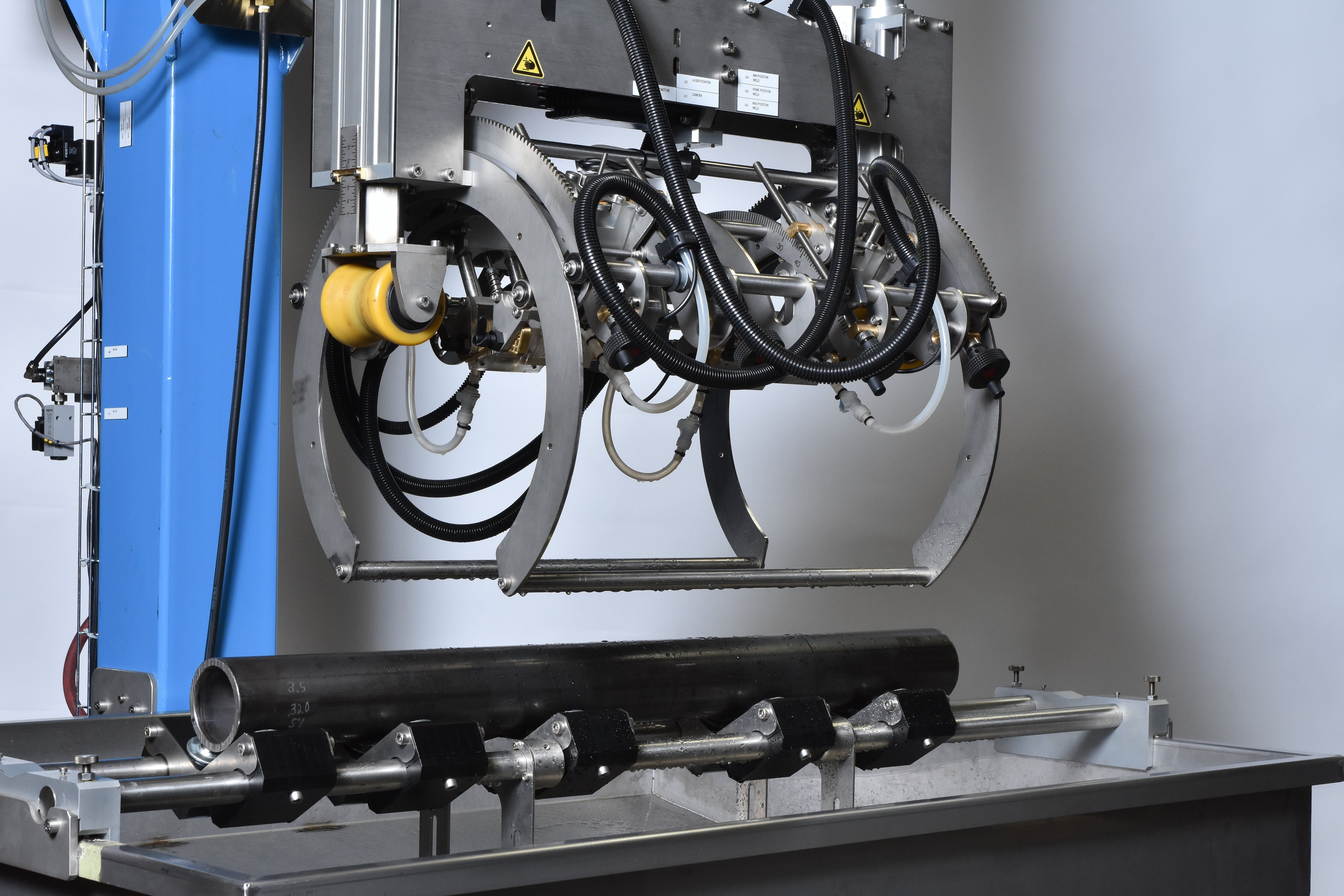

- The Echomac® PA TW Weld Zone Tester provides electronic scanning to detect defects in tube and pipe caused by scarfing or welding processes in the entire weld zone area.