MULTIPLE TECHNOLOGY SYSTEMS IN NDT

A multi test for heavy wall, large diameter (up to 500mm) OCTG tube might include:

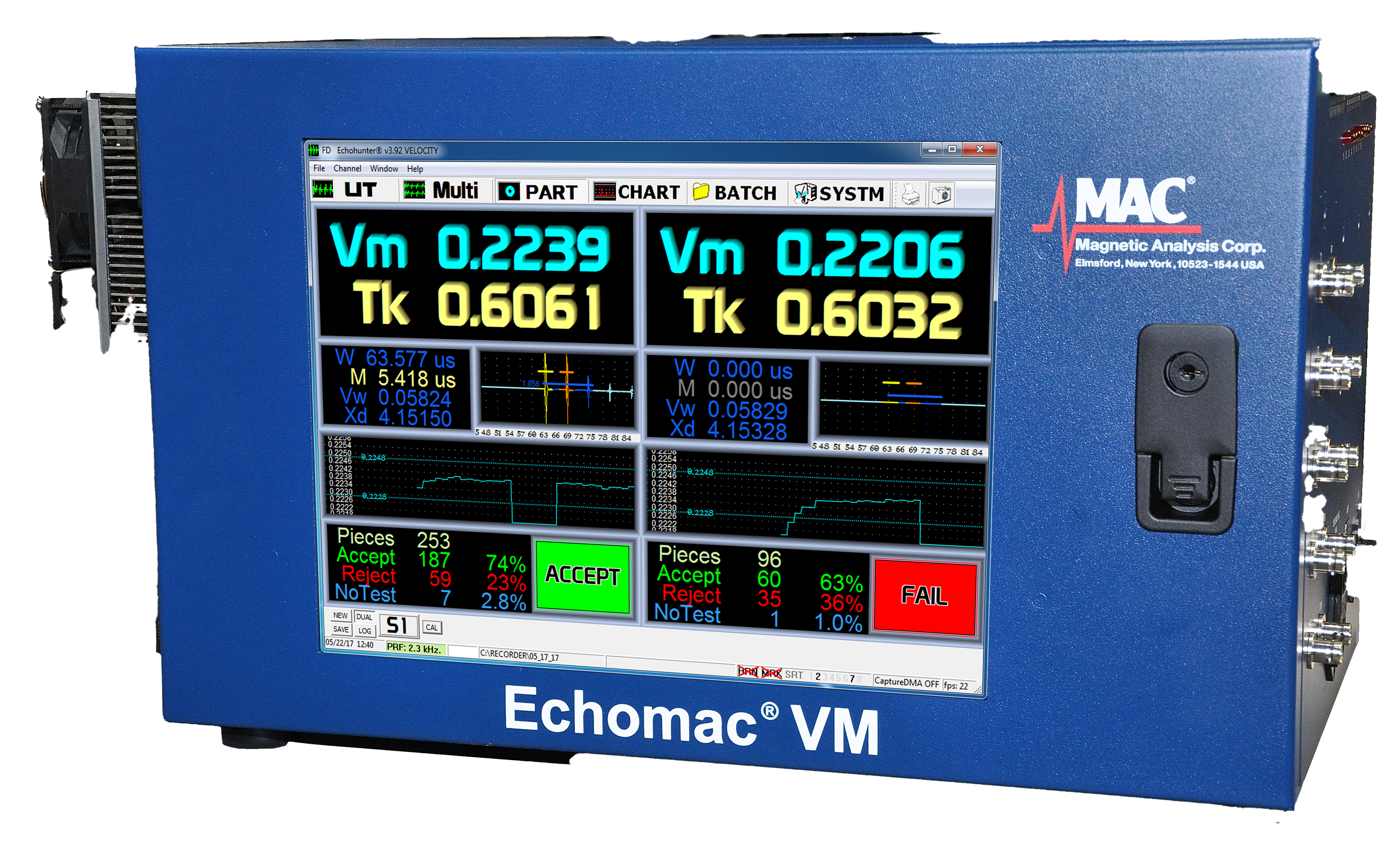

- Echomac® rotary Ultrasonic test for detecting transverse and longitudinal flaws, wall thickness, lamination and ID/OD dimensions.

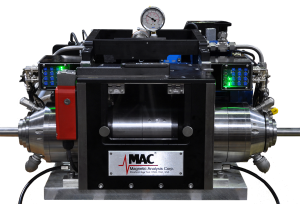

- Rotoflux® flux leakage test to detect seams, laps, weld line defects, and transverse and longitudinal defects.

- Together, these dual technologies provide a far more comprehensive test. The Ultrasonic technology provides critical full inspection capability, including shear wave inspection for longitudinal and transverse defects at any quality level and wall thickness measurement and lamination detection. The addition of the UT rotary to the magnetic flux leakage testers provides complete all-direction test capability and gives the user full flexibility to optimize the pipe inspection process.

- The two flux leakage units can test to 10% OD and ID notch levels up to approximately 14mm wall thickness and 5% OD and ID levels for thickness up to 12mm.

- The result of the combined test technologies is a system that is compliant with API 5CT and 5L, ASTM E570 and other standards, including those that require Ultrasonic testing as the first method and a second method at the discretion of the pipe producer.

Related Resources

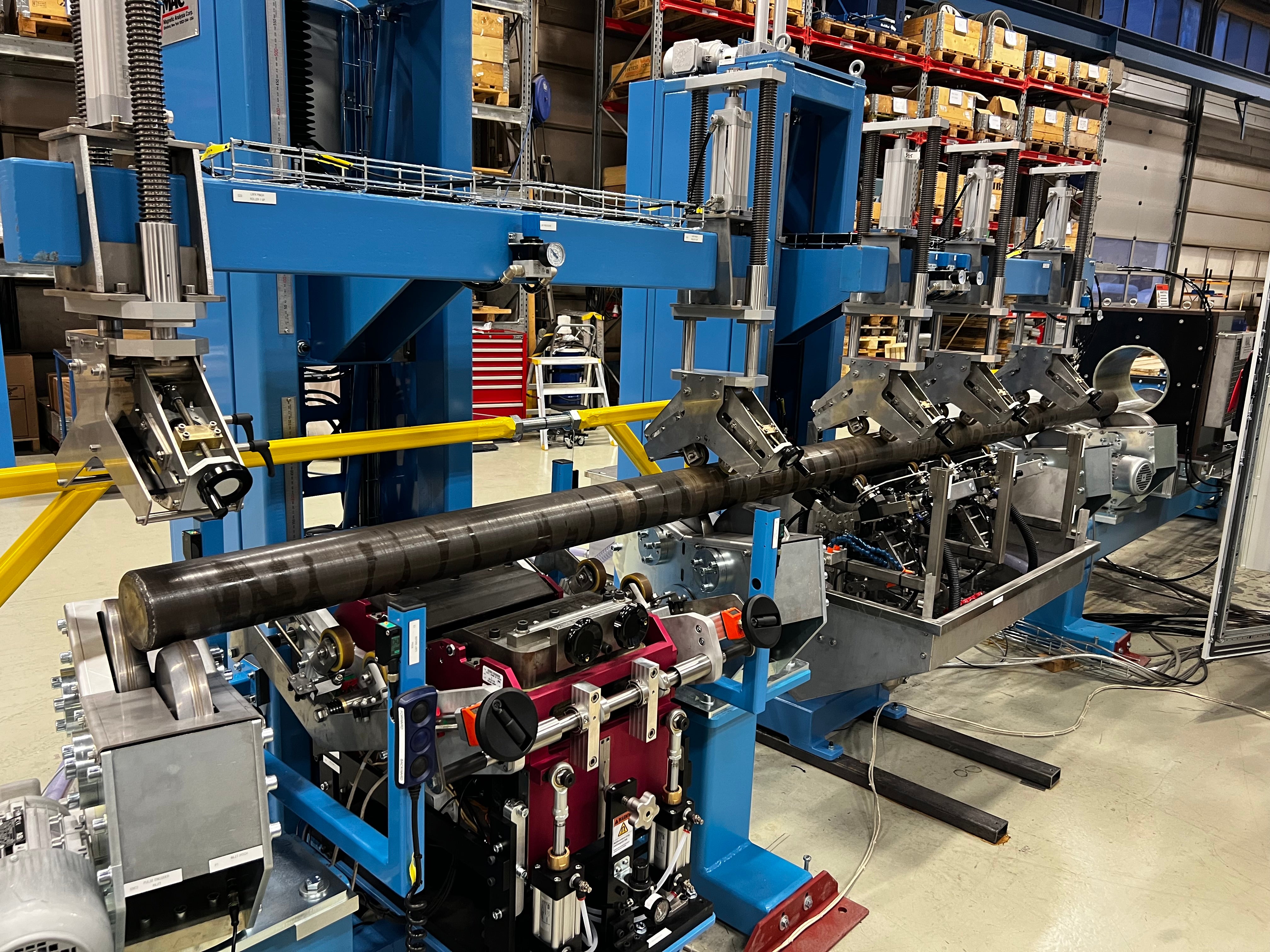

MULTI-TEST SYSTEM FOR AUTOMOTIVE SHOCK ABSORBER TUBING & OCTG

Magnetic Analysis Corp. has supplied a combined ultrasonic/eddy current test system to inspect cold drawn welded tube to be used in manufacturing shock absorbers at a new plant in Monterrey, Mexico, built by Prosankin, formerly known as A-4C-Sankin. The plant’s focus is production and sales of cold drawn tubes primarily for automotive use, although the test system is also designed to provide the future capability of meeting API 5CT testing requirement for oil country tubular goods (OCTG).