MAC’s Weld Zone Profiler is designed to monitor the weld quality of a tube by depicting the “profile” of the completed weld. Unacceptable weld profiles can indicate potential problems associated with irregularities in the scarfing and trimming process, a reduction in the weld size, and other anomalies which compromise the performance of a welded tube

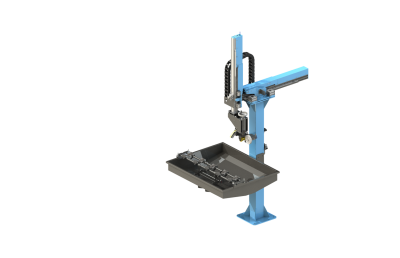

This system incorporates our Echomac® FD electronics, with custom Echohunter® software for profile monitoring, ultrasonic test head mechanics, pillar and guide unit, 1 transducer providing 1 channel for wall/weld profile, downstream video monitoring, and an optional off-line calibration station.

- Pillar and gantry unit for support and stabililzation of test head.

- Special ride shoe to withstand harsh environments.

- Couplant for UT using bubbler technique.

- Custom designed test head scans the weld zone.

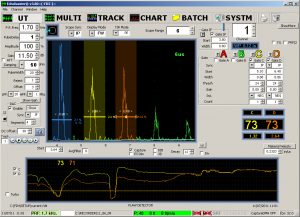

- A-Scan display of profile waveform and strip chart profile view, tracking and recording.

The transducer is mounted in a special ride shoe which is designed to withstand especially harsh environments and the sound beam is coupled to the tube through a short water column using the bubbler technique.

The Echomac® electronics and Echohunter software integrates a UT setup parameter panel, A-Scan display of profile waveform and strip chart profile view, tracking and recording all into a single program for ease of use. Production data can be saved and/or transferred to disc or Ethernet. Printing of setups, wave forms, or strip chart recordings can be done with the push of a button. Summary reports are given at the end of a production run containing the total number of pieces, length tested, number of rejects, time and date stamp, along with material and customer information.

Trained and experienced MAC engineers can provide you with more information on weld profile testing.

ECHOMAC® FD6

For Flaw Detection, Thickness & Dimensional Measurement in Tube & Bar

- Versatile Ultrasonic tester with superior performance and versatile, intuitive operation.

- For full inspection of tubes, pipes and bars, plate and weld.

- Operate on or off line.

- Upgrade and/or replace older ultrasonic testers.

- Use with rotary, spin-the-tube, squirter and bubbler installations.

You may also like

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar

For use with Magnetic Analysis Test Systems

MAC's modular design Feed Systems provide mechanical handling of bars and tubing as they enter and leave a test station.