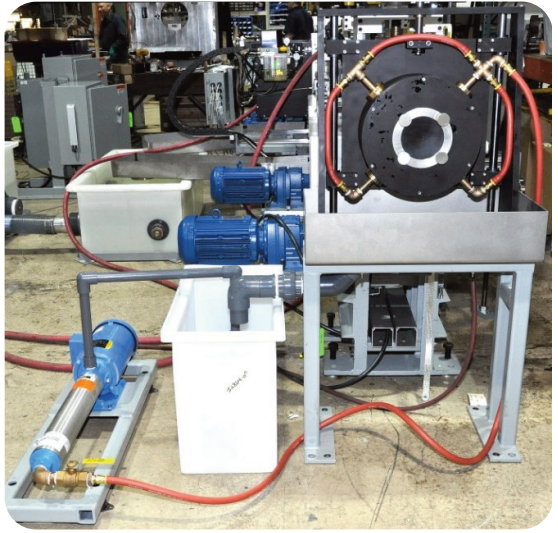

Flux Leakage Tester for Detecting Surface Defects in Hot Rolled Black Steel Bar

- Designed to test hot rolled bar from 15mm to 130mm in diameter.

- Incorporates wireless signal transfer features to minimize noise while maximizing sensitivity.

- Detects longitudinal flaws as small as 0.1mm deep on hot rolled bars and rods, depending on the material condition.

- Operates up to 1500 rpm, depending on product diameter.

- A simple adjustment tool allows for quick resetting for dimensional changes.

- Operates with Rotoflux® AC electronics.

The Rotoflux® AC combines superior technology and performance, and offers these additional important features:

- Provides full quadrature detection to preserve phase selectability.

- Choice of all phase and chord gates, similar to a conventional Eddy Current tester.

- New Probe screen offers sensitivity and phase adjustment for each individual channel.

- Features 2 surface ride Probe Arrays consisting of 8 elements, each covering up to 160mm per rotation.

- Throughput speed of up to 4m/s (800 FPM). Larger diameters require slower FPM speeds.

- Shares common graphic user interface with other MAC systems such as UT and EC testers.

- 180mm unit also available.

You may also like

MAC BAR WASH

Prevent False Test Signals from Contaminated Bar & Tube Surfaces & Reduce Rotary Cleaning Downtime.

DEMAGNETIZERS

Demagnetizers permit efficient, continuous elimination of unwanted magnetism in ferrous rod, wire, bar and tubing