Detects Variations in Alloy, Heat Treatment or Case Depth

- Rapid sorting of ferromagnetic parts.

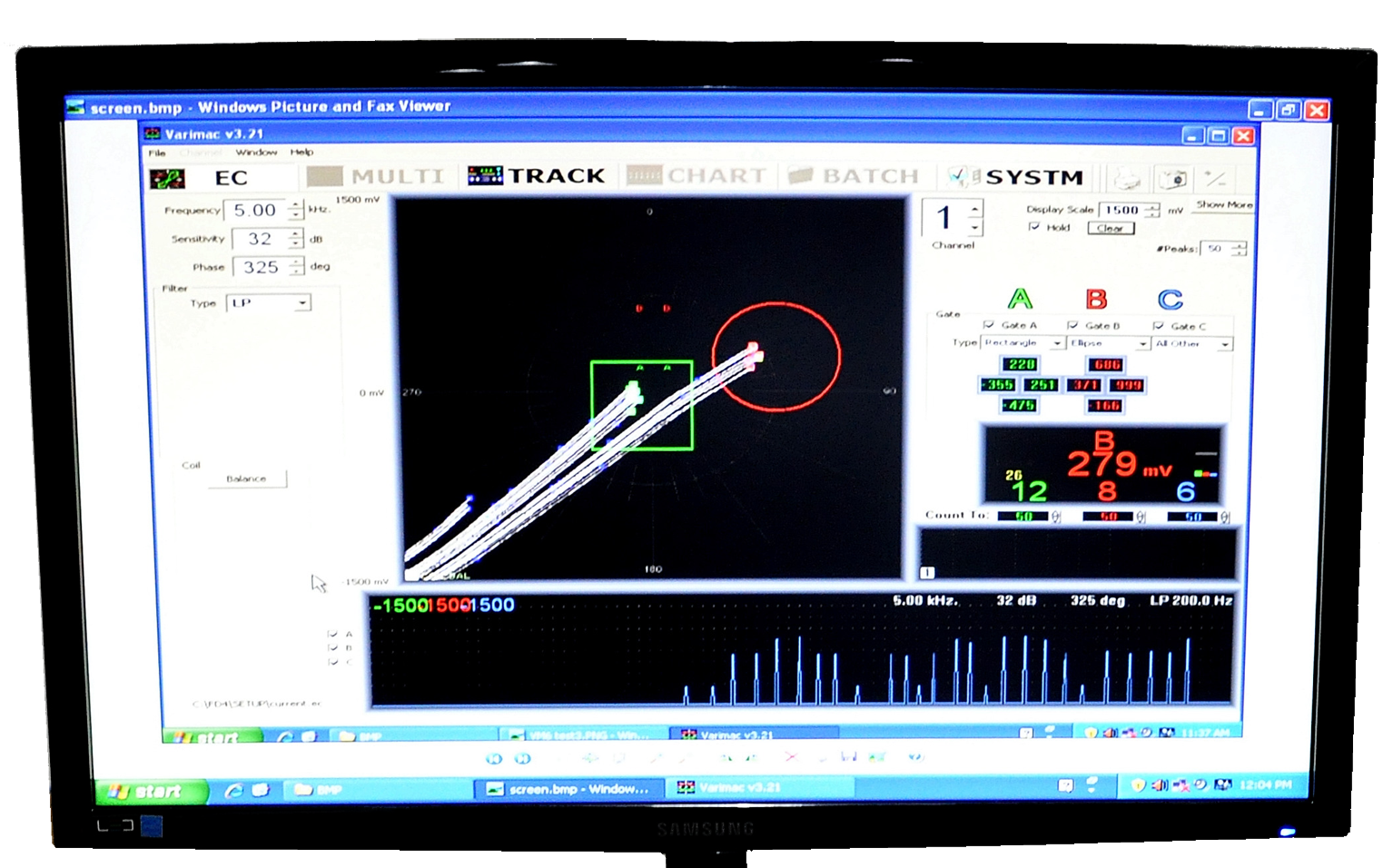

- Offers choice of Polar (Vector) or Lissajou screen displays.

- Inspect tubes or bars at production line speeds.

- Choose any one of 10 pre-set frequencies from 10 Hz to 150 Hz.

- Optional 8-channel multi-frequency software is available.

- System can be set up and monitored on site or via computer at a remote location.

- Monitor presentation provides simultaneous display of the “standard” piece and test piece waveforms for easy comparison.

- Test parameters, including filter, sensitivity, index gate and visible threshold levels, are selected using the keyboard or mouse while observing the effects on the display monitor.

- All functions and test setup parameters in software can also be accessed through a computer LAN network.

- Unlimited test setups can be stored on the hard drive for easy recall.

The Production Comparator VI is a Windows® based test instrument that uses low frequency electromagnetic techniques to inspect magnetic materials for variations in physical characteristics

Features:

- Analyzes signals from the fundamental frequency to its 13th order harmonic to provide a rapid NDT method for efficient sorting of ferromagnetic parts into groups.

- Built-in end suppression with adjustable In-and-Out time based delays, easy one click auto balance and built in self-diagnostics are also included.

- Two adjustable thresholds allow parts to be sorted into three quality levels.

- All setup parameters can be individually locked out to prevent unauthorized changes.

- New optional multi-frequency software allows simultaneous analysis of eight frequencies for a more complex test.

- To maximize the difference between pieces and minimize extraneous readings, the coil current can be adjusted, and one of three filter settings can be selected:

You may also like

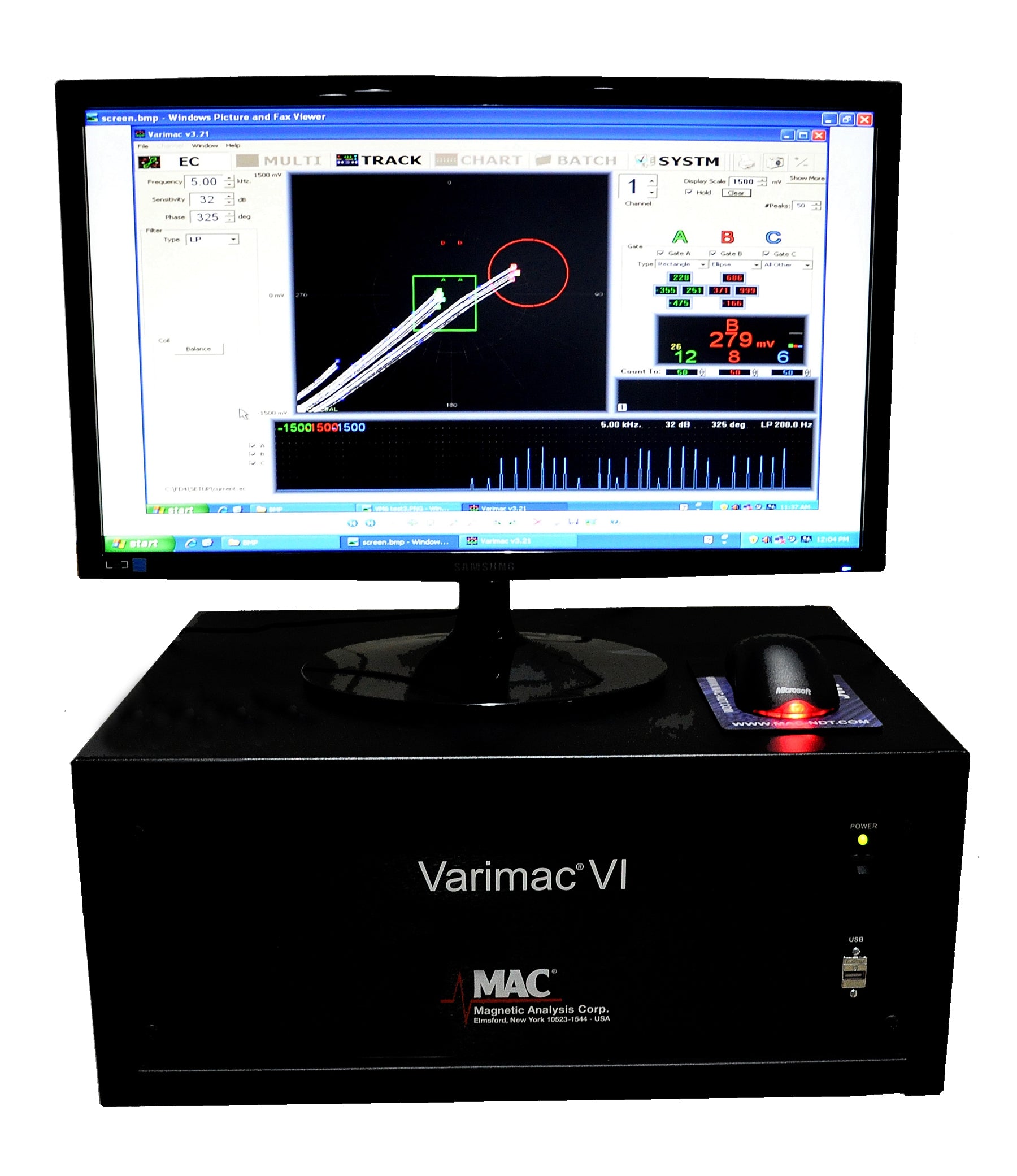

VARIMAC® VI EDDY CURRENT COMPARATOR

Eddy Current Comparator to Test for Hardness, Alloy, Dimensions, & Physical Characteristics in Metal

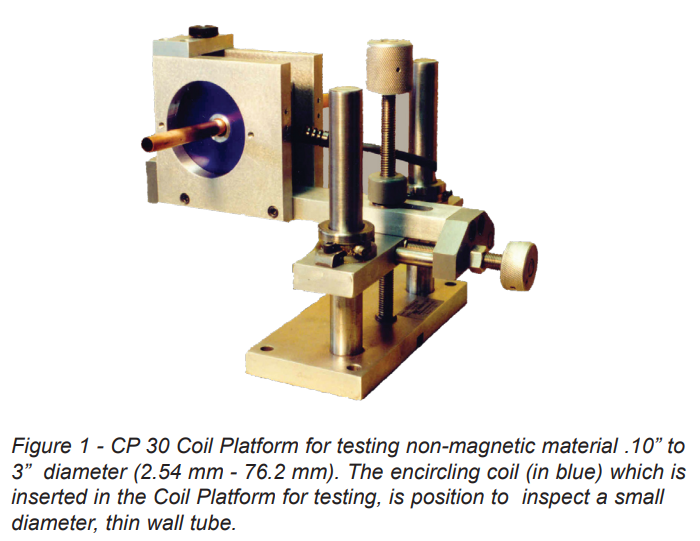

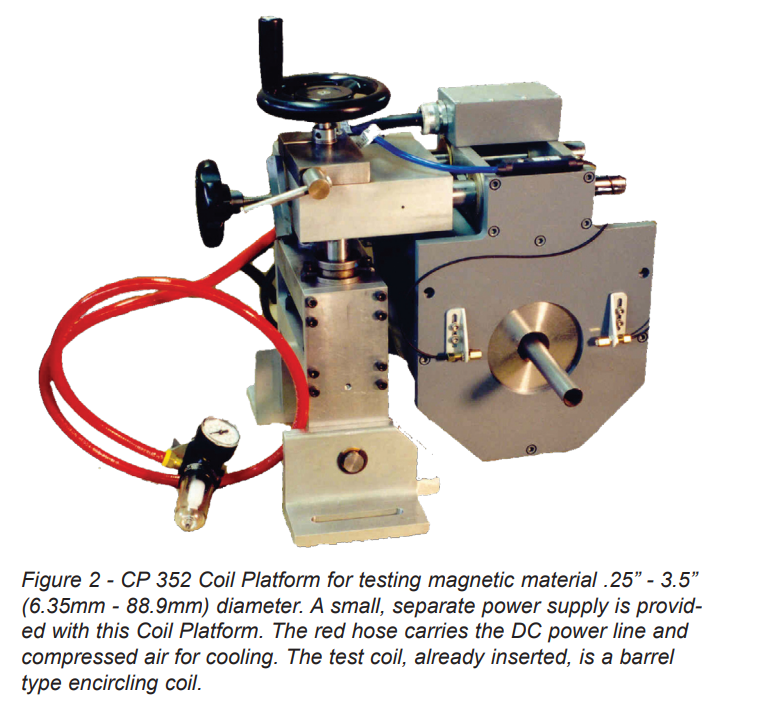

COIL PLATFORMS

Proper positioning of the test coil with respect to the material being tested is a key ingredient of any eddy current inspection system. T