Application

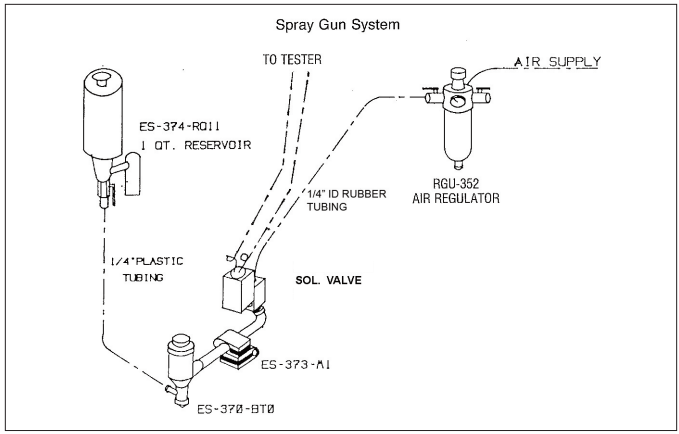

The Model 800 spray marker is designed for use with MAC inspection systems. When the test equipment activates the solenoid valve of the marker, paint is sprayed. The activation time is adjusted by the test equipment. The size of the spray area can be varied by use of different size nozzles.

Description

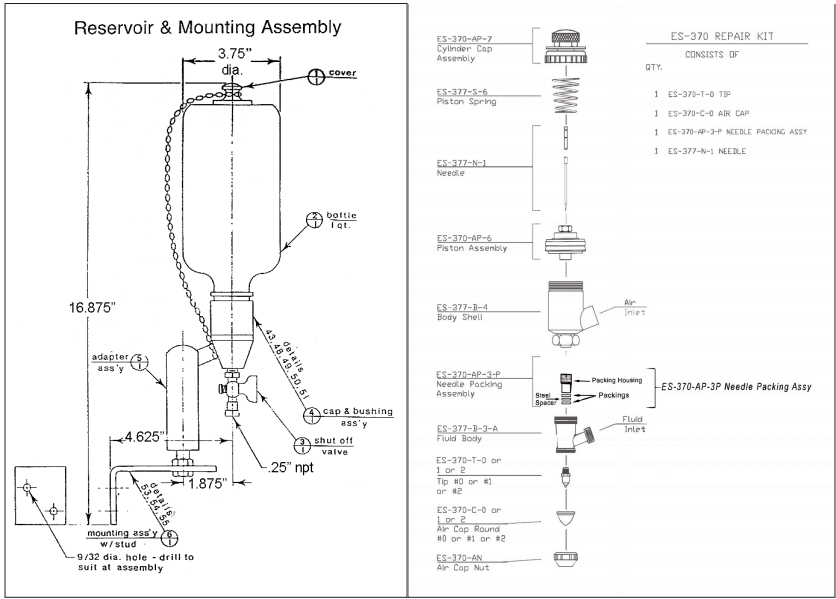

The marker consists of a one quart capacity resrvoir, with an inlet tube leading to a solenoid valve and then to the supply head. The supply head should be positioned between 1” (25.4mm) to 3” (76.2mm) from the material that is to be marked. Air pressure (40 to 80 PSI) aerates the spray and drives it onto the material.

A Filter/Regulator is included in the package to remove water that may be in the airline, and to control air pressure. The marker unit also includes a suitable plug-in cable for attachment to MAC inspection equipment.

Special fast drying ink, with good oil penetration and caustic bath resistance, is available directly from Carco, Incorporated, 10333 Shoemaker, Detroit Michigan 48213. Telephone 313-925-9000.

Utility Requirements

Air Pressure: 80 PSI maximum input recommended

Power:

24 Volts DC standard

120 VAC, 60 Hz, Single phase

240 VAC, 50/60 Hz, Single Phase

You may also like

MAC's modular design Feed Systems provide mechanical handling of bars and tubing as they enter and leave a test station.

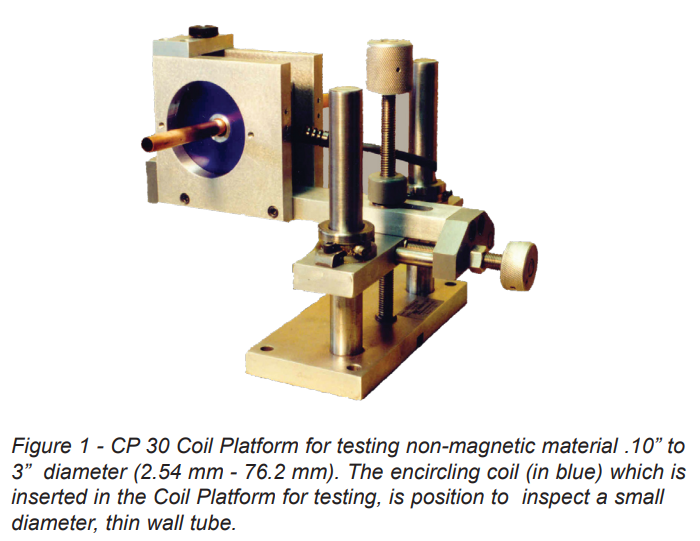

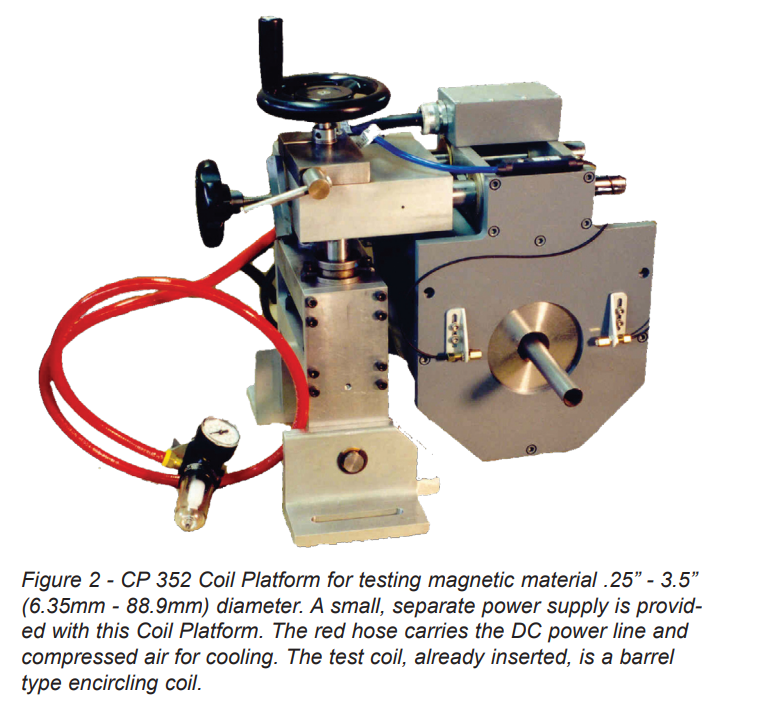

Proper positioning of the test coil with respect to the material being tested is a key ingredient of any eddy current inspection system. T