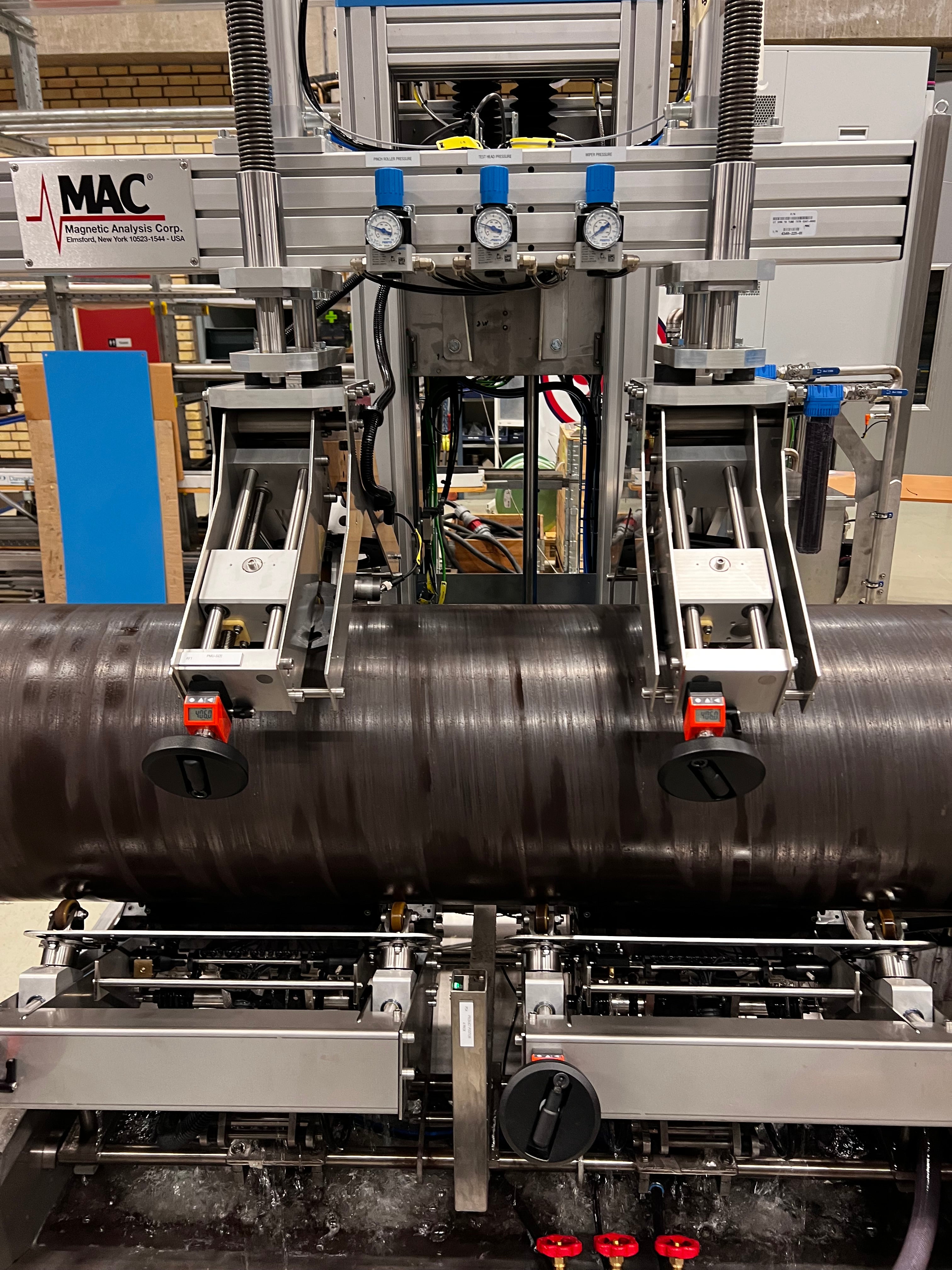

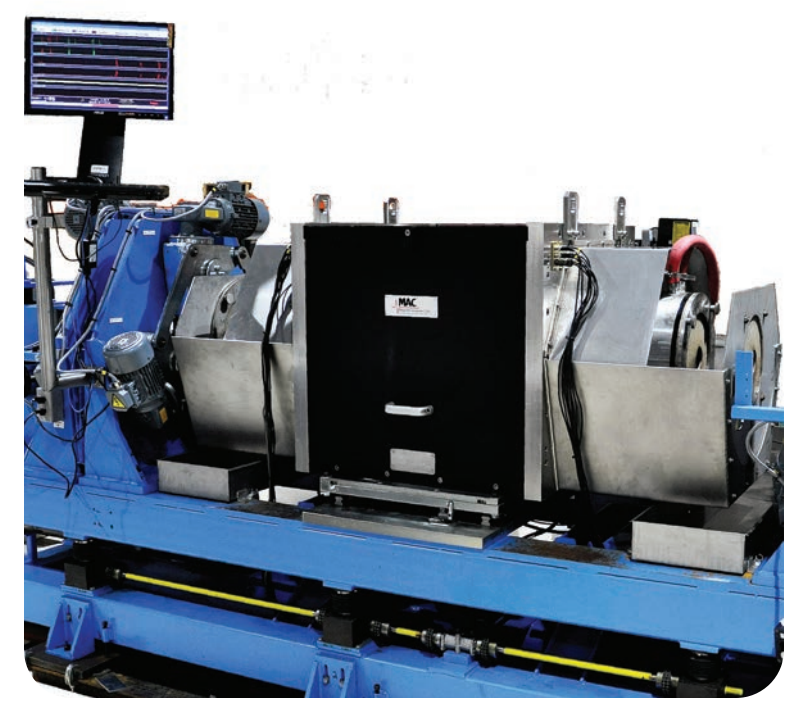

Spin-The-Tube systems for testing product used for transporting gases and fluids in oil, gas and mining operations.

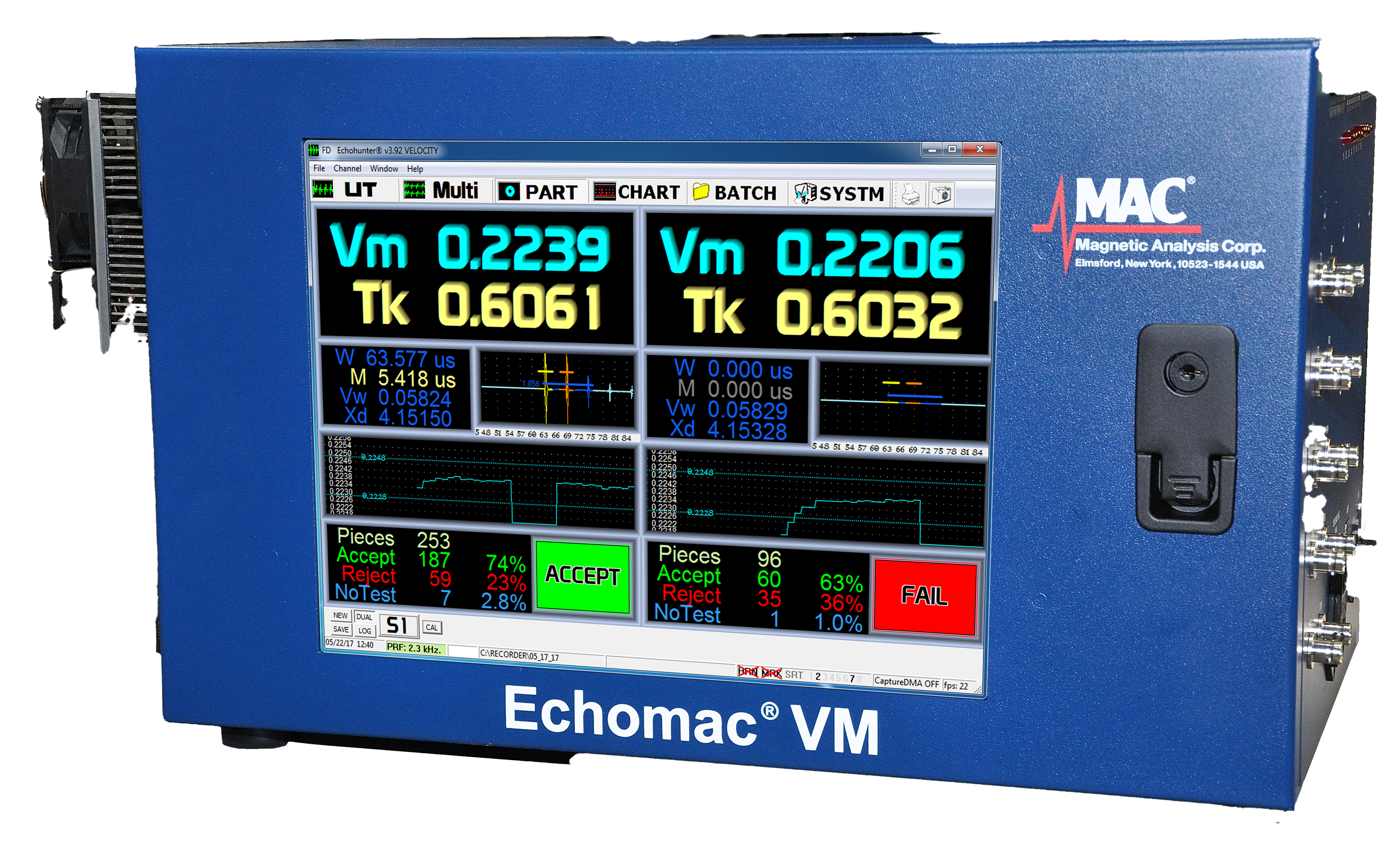

Velocity Measurement to Assess Nodularity in Ductile Iron Cast Automotive Components

Simple, Effective Ultrasonic Instrument With up to 6 Channels

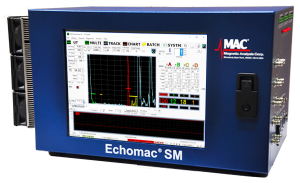

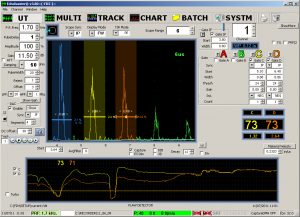

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar

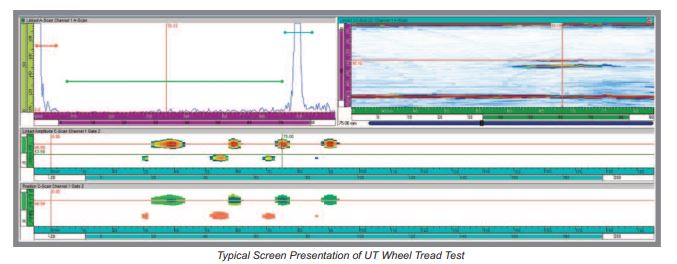

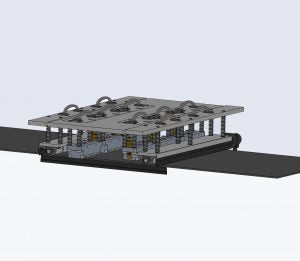

Robust, Cost Effective UT Phased Array System for In-Service Rail Wheel Tread Inspection

For Detecting Weld Zone Defects in Tube & Pipe

The system is scalable, allowing the flexibility of adding channels as needed to handle a large range of part geometries.

For Full Body Inspection of Bar for Defects

For Use in Production Environments

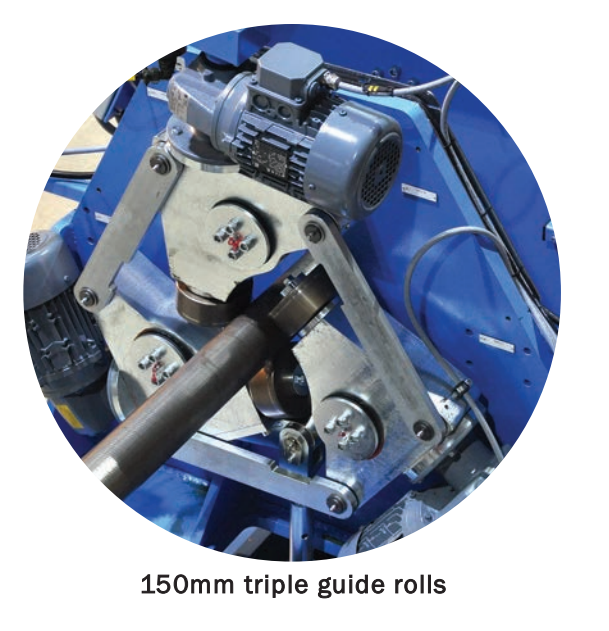

For Inspecting High Precision Small Diameter Tube & Bar

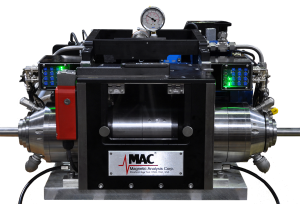

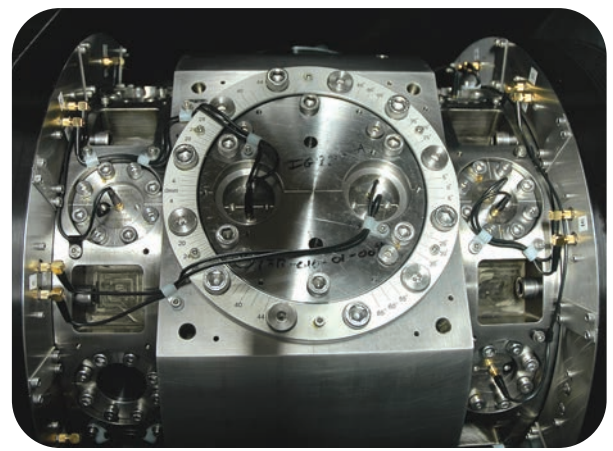

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Spin-the-Tube Inspection System with APC Pitch Control Technology

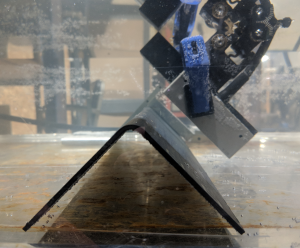

Ultrasonic Inspection Systems for Flat-Sided Material Squares, Rectangles, Hexagonals, Strip

“Heavy Duty” Testers are powered either by a 7.5 HP motor (76F) or by a 10 HP motor (76G).

Model 76E “Standard Duty” Testers feature tanks with an inside length from 6″ to 30″ (150-760 mm).