MAC TO EXHIBIT AT INTERWIRE 2025

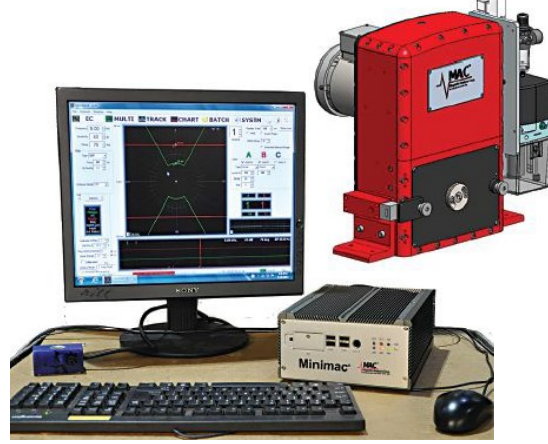

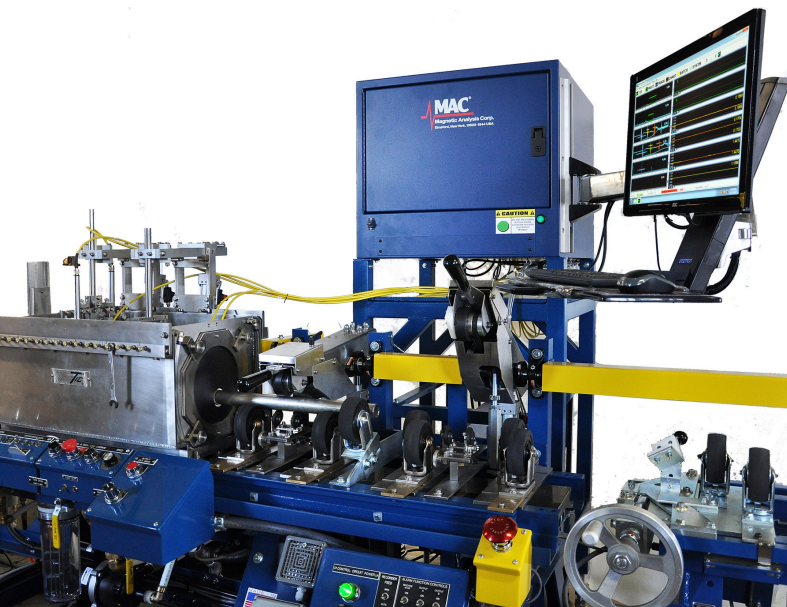

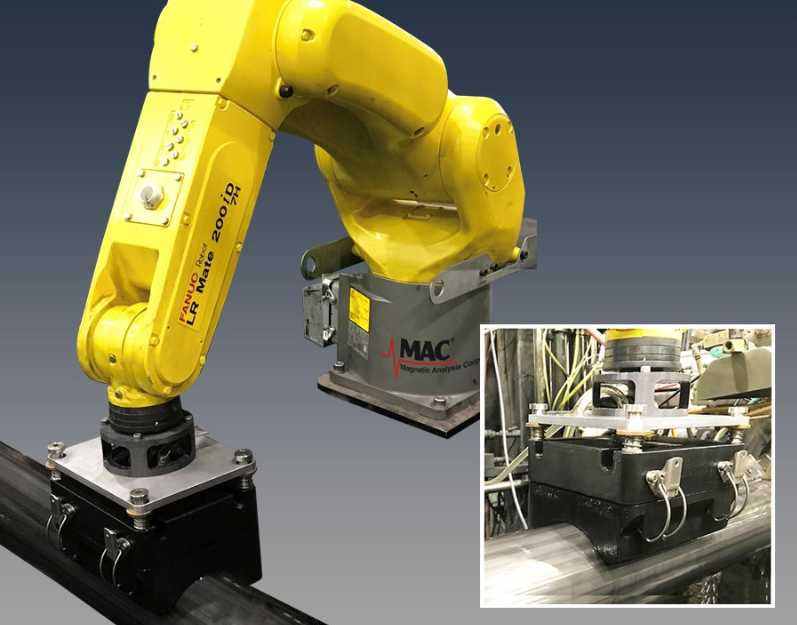

Visitors to Magnetic Analysis Corp.’s Booth #553 at Interwire 2025 May 12 - 15 in Atlanta, GA, will be able to see the Rotomac® 25mm RM, Minimac® II and Quality Grading Software in action via live demonstrations at the booth.

TAKING ULTRASONIC PIPE INSPECTION TO A NEW LEVEL WITH THE ECHOMAC® 500MM TESTER

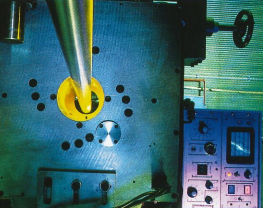

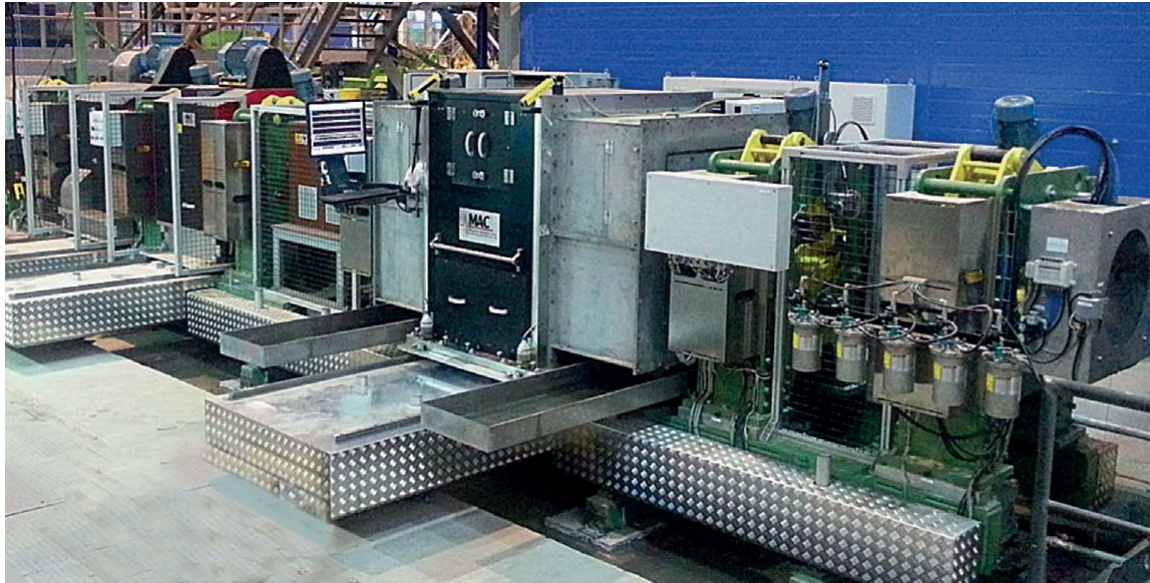

Responding to the expanding supply of natural gas and oil which has spurred a need for larger diameter tube and pipe, Magnetic Analysis Corp. (MAC) has supplied its largest ever model Ultrasonic Rotary tester to a major Russian pipe producer. Part of MAC’s line of Echomac® nondestructive Ultrasonic testers, this model can inspect tube and pipe up to 500mm (19.6”) diameter.

New UT Phased Array Upgrade Program for ROWA & BIS Users

Magnetic Analysis Corp., Sensor Networks, Inc. and Zetec, three NDT leaders, have joined forces to offer the ZMS program, a single alternative for bar and tube producers needing to service and upgrade their phased array systems such as ROWA and BIS for detecting flaw/wall thickness/geometry and lamination.

When It’s Not a Capital Idea, When Leasing Pays Off

A regional environmental analytical laboratory was bidding on a significant piece of new business. The laboratory already had three gas chromatograph systems; however, this job would require a fourth. The director had used the annual capital budget on equipment to upgrade the laboratory’s high-technology equipment to maintain a competitive edge in its markets.

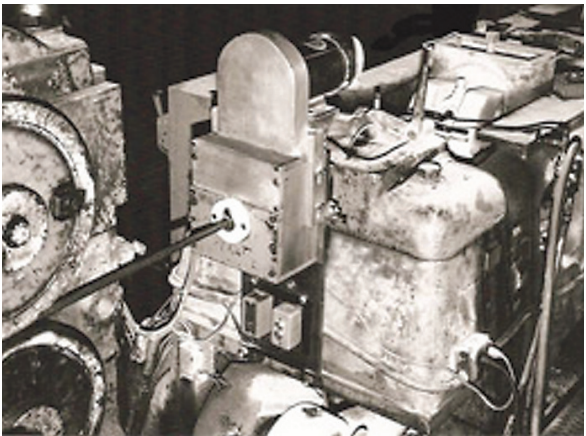

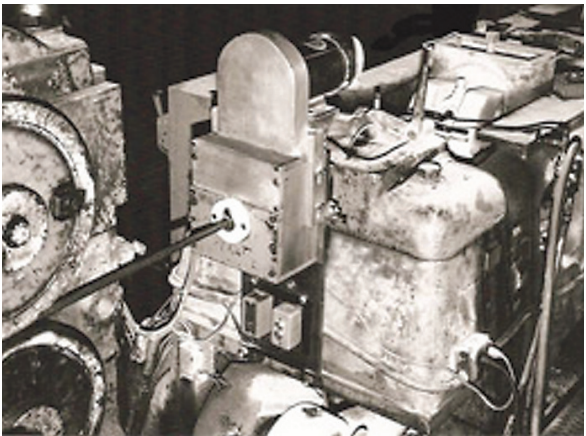

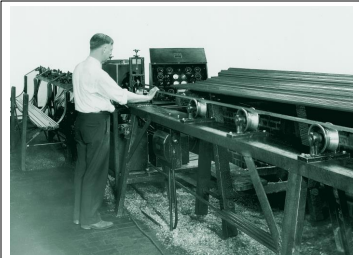

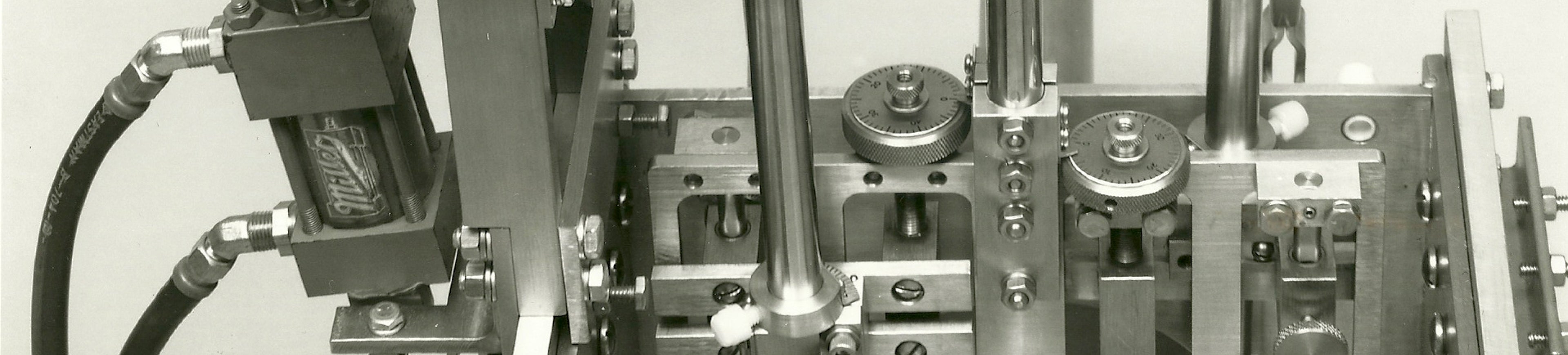

The Origins of Practical EM Testing & the Historical Contributions of MAC to NDT

Magnetic Analysis Corporation, most commonly referred to as MAC, is a major worldwide source of NDT equipment including eddy current, flux leakage, and ultrasonic inspection systems. Since its beginnings to present day, MAC has been the first to market with various types of groundbreaking NDT equipment.

A Look at NDT Testing

Non-destructive testing or NDT has become the go-to quality assurance management tool for the examination of materials and components. Perhaps the best feature about this form of testing is that it allows materials to be examined without changing or destroying their usefulness.

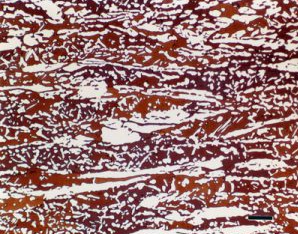

NDT of Duplex Stainless Steel

This paper will discuss the selection of inspection methods for testing Super Duplex stainless product for the offshore energy exploration, petrochemical, food & beverage, and power generation industry. We will show how Eddy Current and Ultrasonics will meet requirements set up by ASTM, and EN standards in regards to Super Duplex stainless steel.

Modern Comparators

Rapid inspection of fasteners and metal parts for properties such as heat treatment, hardness, and alloy is a key requirement in meeting today’s stringent specifications in the automotive, aerospace, nuclear, and similar demanding industries. Improperly heat-treated parts can result in costly machining issues, rework, lost production time, and product failure.

Testing Wire & Rod

Eddy current technology is the go-to wire and cable testing method for checking continuity, alloy, and other conditions as well as for locating welds and splices.

Advances in Large Diameter Pipe Inspection

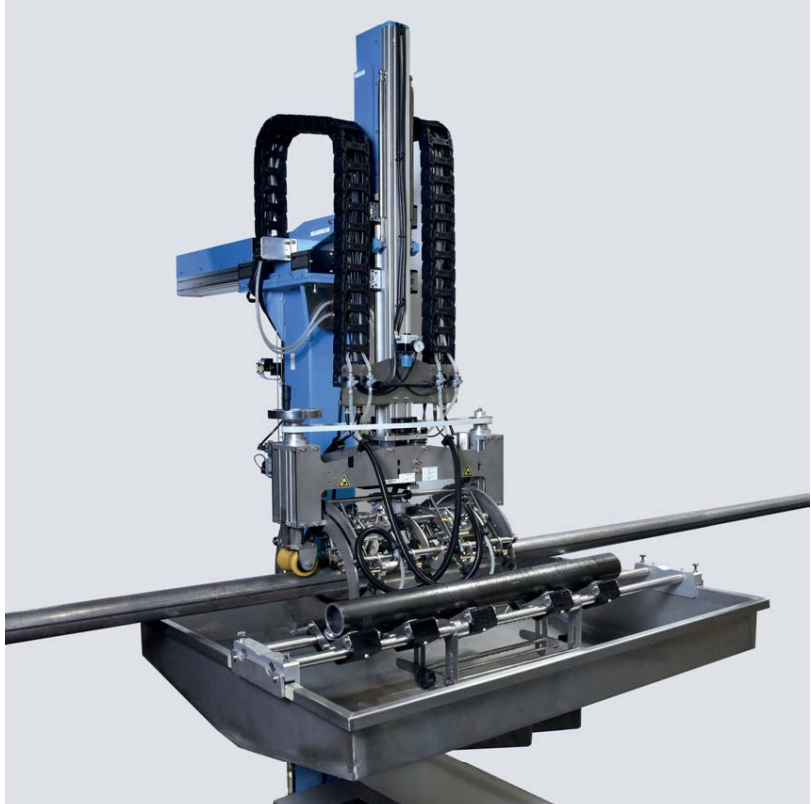

A new design has been developed for the ultrasonic testing (UT) of drawn over mandrel seamless carbon steel tube and pipe that enables manufacturers to test with fewer adjustments to accommodate varying diameters of material, without the need for time-consuming configuration changes.

MAC A Major Player in the NDT Industry

Since being founded in 1928 in Long Island City, New York, Magnetic Analysis Corporation (MAC) has 85 years of experience in the nondestructive testing (NDT) industry. As one of the first companies in the world to develop a fully computerized rotary eddy current tester, MAC is truly a world-class NDT pioneer.

MAC TO EXHIBIT AT INTERWIRE 2025

Visitors to Magnetic Analysis Corp.’s Booth #553 at Interwire 2025 May 12 - 15 in Atlanta, GA, will be able to see the Rotomac® 25mm RM, Minimac® II and Quality Grading Software in action via live demonstrations at the booth.

TAKING ULTRASONIC PIPE INSPECTION TO A NEW LEVEL WITH THE ECHOMAC® 500MM TESTER

Responding to the expanding supply of natural gas and oil which has spurred a need for larger diameter tube and pipe, Magnetic Analysis Corp. (MAC) has supplied its largest ever model Ultrasonic Rotary tester to a major Russian pipe producer. Part of MAC’s line of Echomac® nondestructive Ultrasonic testers, this model can inspect tube and pipe up to 500mm (19.6”) diameter.

New UT Phased Array Upgrade Program for ROWA & BIS Users

Magnetic Analysis Corp., Sensor Networks, Inc. and Zetec, three NDT leaders, have joined forces to offer the ZMS program, a single alternative for bar and tube producers needing to service and upgrade their phased array systems such as ROWA and BIS for detecting flaw/wall thickness/geometry and lamination.

When It’s Not a Capital Idea, When Leasing Pays Off

A regional environmental analytical laboratory was bidding on a significant piece of new business. The laboratory already had three gas chromatograph systems; however, this job would require a fourth. The director had used the annual capital budget on equipment to upgrade the laboratory’s high-technology equipment to maintain a competitive edge in its markets.

The Origins of Practical EM Testing & the Historical Contributions of MAC to NDT

Magnetic Analysis Corporation, most commonly referred to as MAC, is a major worldwide source of NDT equipment including eddy current, flux leakage, and ultrasonic inspection systems. Since its beginnings to present day, MAC has been the first to market with various types of groundbreaking NDT equipment.

A Look at NDT Testing

Non-destructive testing or NDT has become the go-to quality assurance management tool for the examination of materials and components. Perhaps the best feature about this form of testing is that it allows materials to be examined without changing or destroying their usefulness.

NDT of Duplex Stainless Steel

This paper will discuss the selection of inspection methods for testing Super Duplex stainless product for the offshore energy exploration, petrochemical, food & beverage, and power generation industry. We will show how Eddy Current and Ultrasonics will meet requirements set up by ASTM, and EN standards in regards to Super Duplex stainless steel.

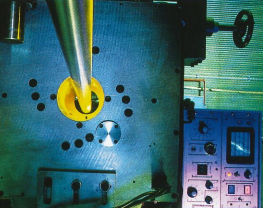

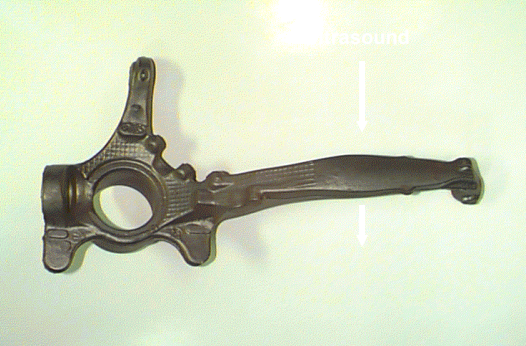

Modern Comparators

Rapid inspection of fasteners and metal parts for properties such as heat treatment, hardness, and alloy is a key requirement in meeting today’s stringent specifications in the automotive, aerospace, nuclear, and similar demanding industries. Improperly heat-treated parts can result in costly machining issues, rework, lost production time, and product failure.

Testing Wire & Rod

Eddy current technology is the go-to wire and cable testing method for checking continuity, alloy, and other conditions as well as for locating welds and splices.

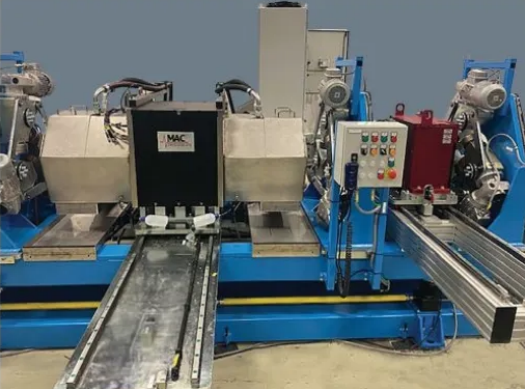

Advances in Large Diameter Pipe Inspection

A new design has been developed for the ultrasonic testing (UT) of drawn over mandrel seamless carbon steel tube and pipe that enables manufacturers to test with fewer adjustments to accommodate varying diameters of material, without the need for time-consuming configuration changes.

MAC A Major Player in the NDT Industry

Since being founded in 1928 in Long Island City, New York, Magnetic Analysis Corporation (MAC) has 85 years of experience in the nondestructive testing (NDT) industry. As one of the first companies in the world to develop a fully computerized rotary eddy current tester, MAC is truly a world-class NDT pioneer.

Detecting Metallic Inclusions And Defects In Copper Tube

The Victaulic copper connection system complies with EN1057 half hard copper tubing sizes DN50 to DN150 (2 to 6") and can withstand pressures up to 2,450kPa/355psi depending on the type and size of copper tubing. The product line consists of WRAS-approved Style 606 rigid coupling with grade ‘EW’ EPDM gasket for joining copper tubing and a range of full-flow, standard radius wrought copper fittings supplied with grooves.

Planning Ahead for a Successful NDT System

As a start, suppliers should recognize that it is fast becoming mandatory for any long stock producer to pass 100 percent of the product through a test station to assure that customer expected quality levels are met.

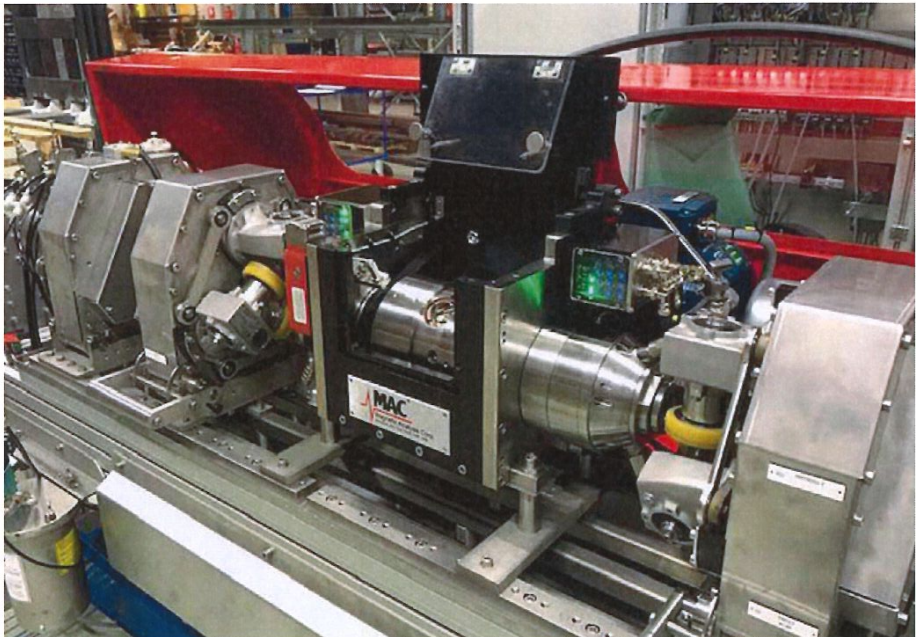

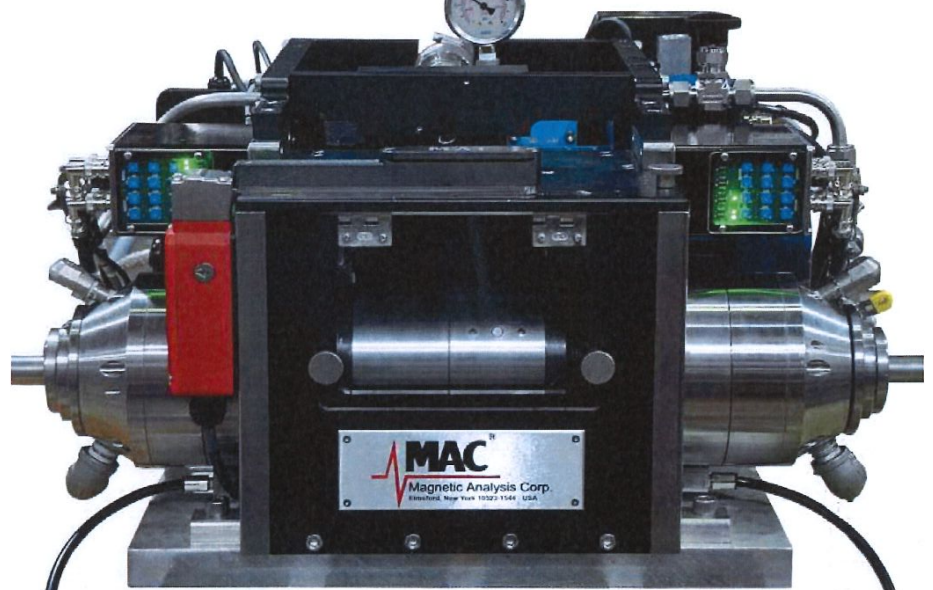

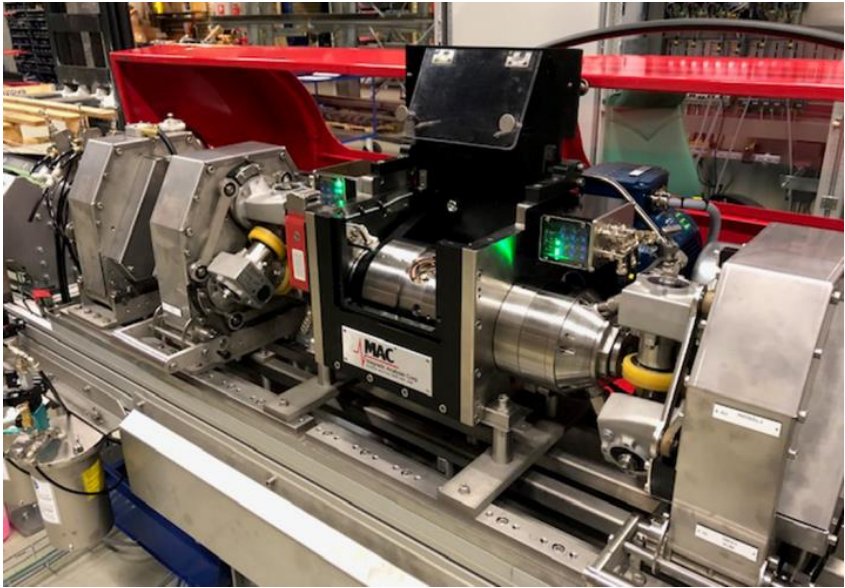

Meeting Standards For Testing Large OCTG Tube and Pipe

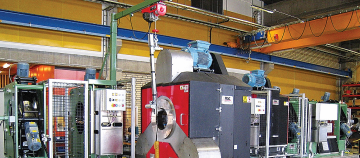

Magnetic Analysis Corp. (MAC) has recently supplied a test system to a Russian mill to inspect tube and pipe, up to 500mm (19.6”) diameter. The system features MAC’S largest ever Echomac® Ultrasonic Rotary tester combined with 500mm Rotoflux® Transverse and Longitudinal testers.

High Performance Testing

MAGNETIC Analysis Corporation (MAC) will feature the new Minimac 55 eddy current tester at this year’s Tube Southeast Asia show in Bangkok, Thailand, in September.

MAC Spotlight Article

Vielseitig, flexibel und nah am Kunden: Die US-amerikanische Magnetic Analysis Corporation (MAC) ist ein führender Anbieter zerstörungsfreier Prüfgeräte. Das Unternehmen, das 1928 gegründet wurde, hat seinen Sitz in Long Island City, New York. In den vergangenen 87 Jahren hat sich das Unternehmen zu einem weltweit tätigen Anbieter zerstörungsfreier Prüfgeräte entwickelt.

MAC So Much More than an Equipment Maker

Since being founded 87 years ago in Long Island City, New York, Magnetic Analysis Corporation (MAC) has become a leader in the nondestructive testing industry. The company was responsible for developing the first American made system using electromagnetic principles for the detection of flaws in steel products.

MAC A Global Partner in NDT SOLUTIONS

Since being founded in Long Island City, New York, in 1928, Magnetic Analysis Corporation (MAC) has grown to become a worldwide leader in the nondestructive testing industry. The company developed the very first American-made nondestructive testing system using electromagnetic principles for the detection of flaws in an assortment of steel products.

MAC Features Tube, Bar And Wire Test Systems

FIVES, an industrial engineering Group with a heritage stretching back more than 200 years, designs and supplies machines, process equipment and production lines for the world’s largest industrial groups, including the aluminum, steel, glass, automotive, aerospace, logistics, cement and energy sectors.

MAC Eddy Current Tester Received Strong Interest

The new high-speed Rotomac® eddy current tester for small diameter wire and rod from Magnetic Analysis Corp. (MAC) received strong interest from wire 2016 attendees.

MAC Introduces Improved Ultrasonic Weld Line Tester

Magnetic Analysis Corp. has recently supplied a new Echomac® WLD ultrasonic weld line test system for an Ohio tube mill. Featuring new operating conveniences for inspecting tube weld zones on-line during continuous production, the system is designed to test for longitudinally oriented defects that are typical of the ERW welding process.

MAC Appoints President/CEO

Mr. Boden is now focused on broadening the firm’s product offering in order to take advantage of new opportunities that have arisen. “Boden’s work in expanding overseas operations and strengthening the sales force and office procedures is providing a firm basis for future successful initiatives under his leadership,” commented MAC chairman William S. Gould 3rd.

MAC System Tests For Eccentricity During Tube Drawing

MAC system tests for eccentricity during tube drawing ECCENTRICITY, where the OD and ID are not concentric, is a problem that is most often created during extrusion of the billet before being drawn into a tube.

Full Body Ultrasonic Inspection Of Spinning Tube

Magnetic Analysis Corp. (MAC) has developed an Ultrasonic Spin-the-Tube inspection system utilizing MAC’s Automated Pitch Control (APC) Technology, and a premium grade conveyor designed specifically for testing applications.

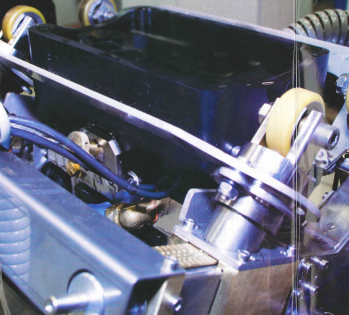

Top Products Of 2016: Rotary Eddy Current Tester

The high-speed Rotomac® rotary eddy current tester for small diameter wire and rod is available from Magnetic Analysis Corp., Elmsford, NY, USA. The Rotomac eddy current tester is designed for ease of use and superior performance in detecting longitudinal, seam-type defects in small diameter wire and bar from 2 to 20 mm diameter.

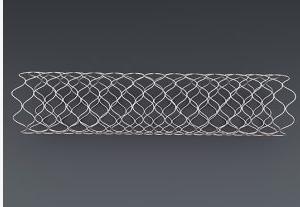

Testing Small Diameter Nitinol Wire

Magnetic Analysis Corp. has introduced an eddy current test for detecting cracks and inclusions in Nitinol wire. An alloy made of approximately equal parts nickel and titanium, Nitinol is referred to as a SMA (shape memory alloy). It is often used in critical surgical applications such as stents and heart valves

There’s Optimism In the Air: Magnetic Analysis Corporation

Dudley Boden, president and CEO of Magnetic Analysis Corporation, believes the steel industry is at the beginning of a recovery. Activity levels in the OCTG sector are beginning to increase and, despite the obvious challenges presented by the current economic and geopolitical climate, there’s light at the end of the tunnel.

Ultrasonic/Eddy Current System for Automotive Shock Absorber Tubing

Magnetic Analysis Corp. (MAC) has supplied an ultrasonic/eddy current multi-test system to inspect cold-drawn welded tube used in the production of shock absorbers at a Monterrey, Mexico plant operated by Prosankin (formerly A-4C-Sankin).

MAC To Exhibit Latest Echomac® UT Instrument At Fabtech

MAGNETIC Analysis Corp (MAC) will be featuring its Echomac® FD-6/6A ultrasonic test equipment at booth 810018 at the FABTECH 2017 show. Information will be available on a variety of applications, ranging from full-body testing for spinning tube and weld zone inspection during production to 500mm ultrasonic/flux leakage multi-test systems for large-diameter pipe.

Critical NDT Applications

Nondestructive testing, commonly referred to as NDT, was first developed in the late 1800s. In the years since, a variety of technologies have been developed, including Eddy Current Testing (ECT) and Ultrasonic Testing (UT), which will be our focus. These two methods often complement one another when used together.

Exploring NDT options for energy-related tube, pipe products, Authored by Joseph Baldauff, VP Technology

As the oil and gas industry has changed over the years, the quality standards for tube and pipe have gained in importance. Drilling is taking place in more remote locations, often many miles offshore; horizontal drilling capability allows drilling at ever-greater distances; and to find new sources, drilling is going deeper than ever before.

Velocity Measurement for Determining Ductility and Nodularity in Cast Iron, Authored by Zhongqing You, PhD, VP Eng.

Traditional Ultrasonic Testing • Sound travels into the part, reflecting from a defect – “Flaw Detection” • Reflector size is also determined by signal amplitude – “Flaw Sizing” • Sound travels into the part and returns after a measurable length of time – “Thickness Gaging”

The Test of Time: Magnetic Analysis Corp. Celebrates 90 Years

ELMSFORD, NY, June 11, 2018—Magnetic Analysis Corporation (MAC), a leader in nondestructive testing, is celebrating 90 years of designing and supplying innovative inspection instruments and systems for metal manufacturers throughout the world.

NDT for Stainless Steel Tube and Bar, Authored by Joseph Baldauff, BDM

Nondestructive Testing (NDT) has been around for many years, but what we are seeing today is a swift growth in when it needs to be used. More and more makers of stainless steel products are finding they must insist on the highest quality possible raw stock for their production needs.

MAC’s Echomac® FD-6A and TACTIC UT Immersion System for Critical Applications

A recent test system supplied to a producer of titanium tubes for nuclear applications incorporates MAC’s (Magnetic Analysis Corp.) Echomac® FD-6A ultrasonic instrumentation with TACTIC’s (TAC Technical Instrument Corp.) ultrasonic transducer immersion tank, mechanical handling, controls, and “spin the tube” conveyors to provide a complete turnkey installation.

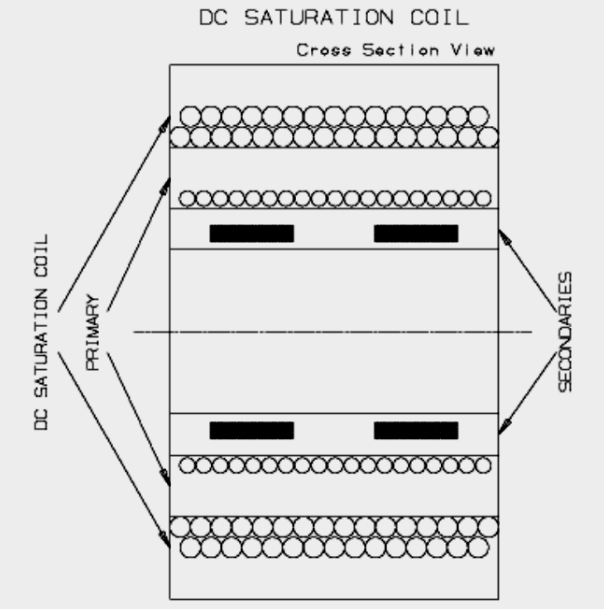

MAC’s New Rotoflux® AC Tester for Testing Hot Rolled Bar

Magnetic Analysis Corp. has recently introduced a new Rotoflux® AC flux leakage tester. The highly sensitive AC Flux Leakage technology is especially well suited to test hot rolled black steel bars and rods that have surface conditions which used to make finding shallow defects very difficult, if not impossible.

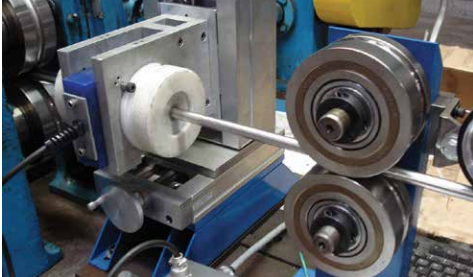

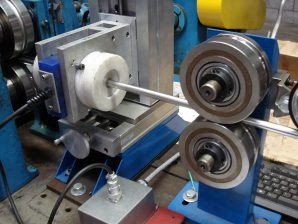

Ultrasonic Rotary to Test Small Diameter Bar

Capable of detecting the very small mandated notches dictated by the aerospace, nuclear, and medical industries. Magnetic Analysis Corporation (MAC) has recently supplied an ultrasonic test system to a major finishing processor of bars for medical components.

William S. Gould, 3rd

Magnetic Analysis Corporation is sad to report the passing of our Chairman and long-time President, William S. (“Bill”) Gould on March 14th. Bill Gould succeeded his father as President of Magnetic Analysis Corp. (MAC) in 1964 and remained in that role until 2007, a remarkable 42-year run in which he successfully built MAC from a small, U.S.-oriented eddy current testing company into a global leader in eddy current, ultrasonic, and flux leakage equipment and services.

MAC Introduces New Echomac® 25mm UT Rotary Tester

The Echomac® 25mm Rotary provides 100% coverage at high throughput rates on thin wall product ranging from 5 to 25mm diameter, and is especially well suited for challenging applications requiring high performance, such as tubular product for nuclear and aerospace installations.

Increasing Repeatability, Reliability and Productivity in Small Diameter SS

With the ever-increasing demand for small diameter stainless and specialty bars, tubes, and wires for critical applications such as automotive, medical, and aerospace, specifications are becoming more restrictive, therefore placing extreme pressure on the productivity of nondestructive testing (NDT) equipment.

MAC Delivers Eddy Current Test System for High Performance Stainless Steel Pipe

Magnetic Analysis Corp. has just delivered a single channel Multimac eddy current off-line test system designed to meet ASTM 999 (American Society for Testing Materials) specifications for testing welded stainless steel pipe.

Choosing and Applying NDT Methods for Round Stock During Production Authored by Joseph Baldauff, VP Technology

Automotive manufacturers require that all mission-critical parts must be manufactured from the highest quality material available to the raw material purchaser. Many ASTM (American Society for Testing Materials), API (American Petroleum Institute), and EN (European) specifications exist because the manufacturers of these parts must assure their customers that they meet all quality requirements.

Testing A-286 Alloy Wire for High Temperature Applications

rum Manufacturing, Inc. has been a trusted supplier of Quality Checking Fixtures and Gages for more than 35 years. Crum Manufacturing specializes in custom quality check Fixtures and Gages for many different products across a wide range of industries including automotive, aerospace and defense, industrial, appliance, plastic injection molding, etc., just to name a few.

MAC to Feature NDT Instruments & Systems at Tube 2020 Düsseldorf

Magnetic Analysis Corp. will feature NDT instruments and systems for testing tube, pipe, bar, and wire at Stand #6/H20 at Tube 2020 Düsseldorf. Highlights include MAC’s latest developments in Eddy Current, Magnetic Flux Leakage (AC and DC), and Ultrasonic technology, including the new Phased Array systems.

Testing Small Diameter, High Precision Tubes

Magnetic Analysis Corporation provides advanced inspection technologies, including eddy current and ultrasonic techniques, for accurate testing of small-diameter, high-performance tubes used in critical applications such as aerospace and nuclear industries.

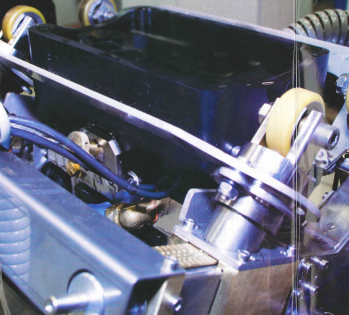

Rotomac® 40mm Eddy Current Rotary to Test Rod

Magnetic Analysis Corp.’s new 40mm Rotomac® Eddy Current Rotary offers enhanced convenience for detecting seam-type surface defects in cold-drawn wire, cut-length bar stock, and parts forming. A single-handle external probe adjustment allows quick, safe dimensional changes without opening the rotary.

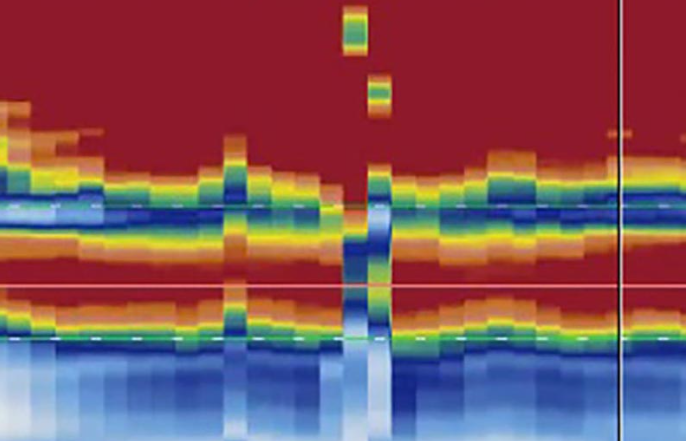

New Turnkey Phased Array Ultrasonic Solution for Evaluating ERW Welded Tube

Magnetic Analysis Corp’s Echomac® Phased Array system offers mechanical, OCTG, and automotive tube manufacturers a high-performance, automated solution to detect longitudinal weld zone defects and/or monitor weld profiles with minimal operator interaction.

The Advantages of Phased Array Technology when Evaluating Welded Tubes Authored by Michael Moist, PAUT Global Sales Manager

Ultrasonic technology has been used for testing ERW welded pipe at various points in the manufacturing process for many years. ERW pipes are manufactured by cold forming a strip of steel into a cylindrical shape using forming rolls, and then having a high frequency electrical current pass between the strip edges increasing the temperature of the steel to its melting point.

Quality Control for Copper Alloys

Magnetic Analysis Corp. offers a range of eddy current test instruments and systems for detecting surface and sub-surface defects in copper and copper alloy wire and bar. This versatile and generally cost-effective technology is being used in a broad range of wire and rod applications.

Testing Small Diameter Copper Rod & Wire During Drawing

A turn-key eddy current test system has been installed at a large copper rod and wire producer in China. The system is fully integrated with the company’s production line, and the quality of each coil of wire is accurately graded, allowing the manufacturer to match the coil quality with a specific customer’s needs and applications.

Testing Wire and Rod Over the Years

Magnetic Analysis Corp., (MAC) joins in congratulating WIRE on its 70 years covering the growth of the wire industry. A designer and manufacturer of nondestructive test systems, MAC was founded in 1928 and since then has made important contributions to testing technology for wire, cable and bar.

Supplying Testing Systems to the Industry Since 1928

Magnetic Analysis Corp (MAC), founded in 1928, offers a full range of eddy current test instruments and systems for detecting surface and sub-surface defects, including laps, slivers, and cracks in non-ferrous and ferrous wire and bar.

Choosing an NDT Process for Tube, Pipe Production Authored by Phil Meinczinger

As market pressures compel tube and pipe manufacturers to search for ways to increase productivity while maintaining adherence to strict quality standards, choosing the optimal inspection method and support system are more critical than ever.

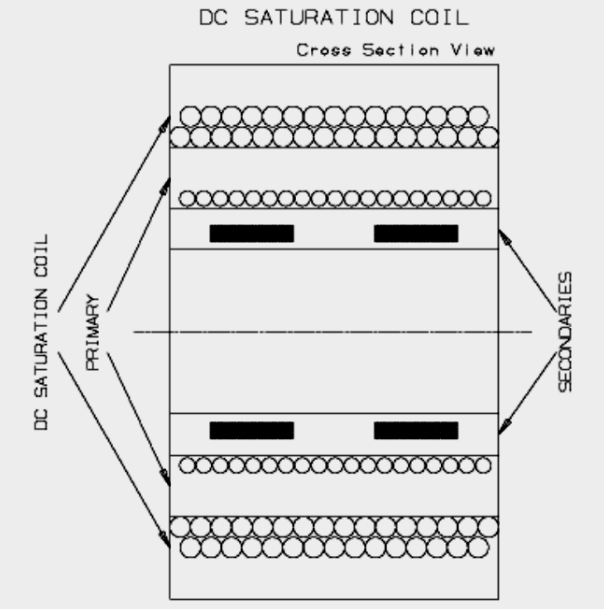

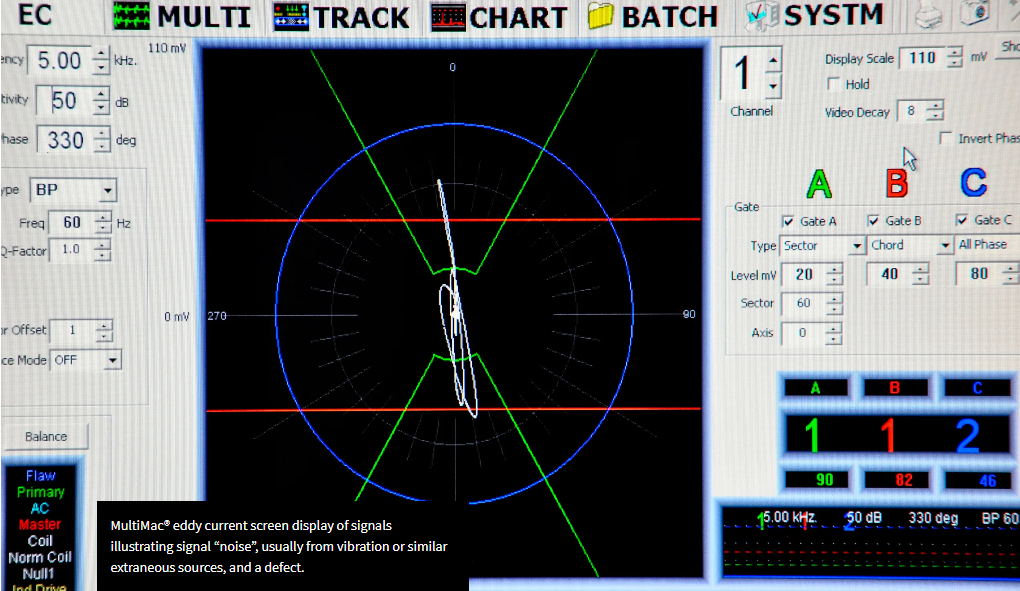

What Can Eddy Current Testing Do for Me Authored by Dean Isbell, ASNT Level III ET & UT

Since the development of eddy current testing in the early to mid-1900s this method has been used to detect defects and properties of many types of metals. The most common applications are testing tubular products for transverse defects, testing bar or wire products for longitudinal surface defects, and testing parts for defects and properties such as hardness.

Magnetic Analysis Corp. Acquires TacTic™ Ultrasonic NDT Systems

Magnetic Analysis Corporation (MAC®), a designer and producer of nondestructive test instruments and systems since 1928, is pleased to announce the asset acquisition of TacTic™, a Division of Laboratory Testing Inc. (LTI), effective February 28, 2022. Originally founded as TAC Technical Instrument Corp.

Magnetic Analysis Corp. to Feature NDT Instruments at Tube 2022 in Germany

MAGNETIC Analysis Corp will feature non-destructive testing instruments and systems for testing tube, pipe, and bar at stand number 6H20 at Tube 2022 Düsseldorf in Germany in June. Highlights at the booth will include MAC’s latest Echomac® Systems for testing ERW welded tube.

Interview with MAC’s Vice President of Sales, Michael Moist

Magnetic Analysis Corp. (MAC) is a company established over 90 years ago providing non-destructive testing (NDT) equipment for the metals industry, primarily producers of tube, pipe, bar, wire, and parts. The company’s focus is in-line automated testing systems ensuring the identification of defects that would impair the functionality of the product.

Automated Test System for Cold Finishing Specialty Steel Mill

Increasing demands for high-quality steel rod and bar requires effective nondestructive (NDT) testing to ensure producers can meet their customer’s needs. As specifications become ever more stringent, NDT technology is consistently evolving new capabilities, adapting to new conditions and improving integration with mill operations.

Using NDT to Ensure Product Quality Authored by Joseph Baldauff, ASNT Level III ET and UT

Industrial heat exchanger users, aerospace, medical, and some military applications require the highest quality materials and also demand high inspection levels for long intermediate products (wire, tube, and bars). Surprisingly, automotive materials can also require the highest quality because defects in safety-critical components or parts integral to engine lifetime or fuel systems can lead to huge expenses.

How to Use Eddy Current Technology to Test Ferrous and Non-Ferrous Wire” Authored by Troy Libby, Engineering Manager

Eddy Current inspection is a technique used for detecting surface seams, cracks, pits, slivers, and internal discontinuities in ferrous and non-ferrous wire. Different test sensor configurations, including encircling coil and rotary probes, can be used. When using encircling coil eddy current testing, the wire passes through the coil excited by an alternating current with one or more drive signals.

Magnetic Analysis Corp. Announces New CEO

Magnetic Analysis Corp., a global leader in instruments and systems for the nondestructive testing of metals, is pleased to announce the appointment of Daniel Lawrence as President and Chief Executive Officer effective November 6th, 2023.

Latest Eddy Current Testing Model to be Showcased at Düsseldorf 2024

Magnetic Analysis Corp. will feature the Minimac® II at its booth. This latest addition to MAC’s range of eddy current test instruments for detecting surface and sub-surface defects such as laps, slivers and cracks in nonferrous and ferrous wire and rod, features an embedded processor host computer, and can be supplied with one or two test channels.

Test Systems for the Wire and Cable Industry

Magnetic Analysis Corp. will be featuring the “Minimac II” at its booth which is to find in the tube section. Wire producers are invited to come over to see products that are applicable to both wire and tube.

Vendors that Become Partners: Collaborate on Effective NDT to Ensure High-Quality Products

One small handful of rejected materials, identified during a run of 30,000 high-precision components, is one handful too many,” asserts John Pechan, Chief Operating Officer at Round Ground Metals® (RGM®).

MAC to Exhibit at Wire Expo 2024

Minimac® II, Magnetic Analysis Corp.’s latest eddy current tester, will be featured at Booth #607 at Wire Expo. This addition to MAC’s range of eddy current test instruments for detecting surface and sub-surface defects such as laps, slivers and cracks in non ferrous and ferrous wire and rod, features an embedded processor host computer, and can be supplied with one or two test channels.

MAC® & Inmar to Feature NDT Test Systems for Tube, Bar and Wire at Tube India 2024

MAC is pleased to announce its participation in Tube India, one of the premier trade shows for the tube and pipe industry. NDT Test instruments and systems for inspecting tube, pipe, bar, and wire will be featured at our booth B 30 in Hall 2.

MAC® at the 2024 Pipe and Tube Conference in Omaha

Magnetic Analysis Corporation (MAC®) is excited to announce its participation in the 2024 Pipe and Tube Conference, taking place on November 13-14 at the Kimpton Cottonwood Hotel in Omaha, Nebraska. This year’s conference promises to be a dynamic gathering for industry professionals, featuring insightful sessions on cutting-edge technologies and networking opportunities.

AUTOMOTIVE TUBE

Precision tubes for the automotive industry must meet the highest performance requirements. MAC’s® Eddy Current, Flux Leakage and Ultrasonic systems are often used to inspect tubes destined to be cut into short lengths to be fabricated into a critical automotive component.

WIRE AND ROD

Eddy Current technology is the go-to wire and cable testing method for checking continuity, alloy, surface flaws and other conditions as well as for locating welds and splices. MAC® instruments can handle a range of metal wire including cut lengths, continuous production, stranded, multi-conductor and insulated cable.

WELDED TUBE

There are many welding processes and many tubing configurations and sizes. MAC has extensive experience testing tubes and pipes using eddy current, ultrasonic, and flux leakage technologies. We have a large base of testing equipment lines being used to meet the many different ASTM, API, EN, ISO and other industry quality standards and or customer driven quality requirements.

TUBE ENDS

All nondestructive test (NDT) methods have some limitation in regard to testing to the very end of a tube. These “untested ends” must be cut off, resulting in a substantial loss of product and revenue. To avoid this loss, a manufacturer needs to develop a method to test these ends to meet the tube integrity requirement.

TESTING BAR

Depending on the requirement, situation and the type of material, Eddy Current, Magnetic Flux Leakage and Ultrasonic testing methods can be used together or alone to inspect round, hex, and square bars for defects and integrity. These inspection methods can be applied to carbon steels, stainless alloys, aluminum, titanium, and all other non-ferrous metals. Bars can be as rolled, peeled or drawn and surface improved.

STAINLESS STEEL ALLOYS

Many materials fall into the category of stainless steel alloys, including austenitic, martensitic, duplex, ferritic and other types of stainless steels. These are most easily NDT tested in both tubular form or in bar stock form (long constant cross section).

INSPECTING STAINLESS STEEL WELDED TUBE

MAC’s Minimac® II eddy current instrument is a high performance yet affordable, compact tester that is used to inspect a range of tubing, including stainless steel, copper, cold drawn welded, and seamless.

PHASED ARRAY UT UPGRADE PROGRAM FOR METAL PRODUCERS USING ROWA & BIS NDT SYSTEMS

For ROWA systems that are no longer operating at their desired level, you can rely on MAC for timely delivery of reliable, price-competitive phased array UT transducers, electronics, computers and software. This allows MAC to offer repair, maintenance, and spare parts to bring existing test systems up to the latest standards for detecting flaw/wall thickness/geometry and lamination.

ROUND & SQUARE BILLETS

MAC can offer Phased Array technology to allow simple testing of both round corner square billets and large round billets. MAC has a unique Phased Array cassette system that allows quick change between the two major geometries (round or square). The transducer assemblies follow the product surface and allow the testing to be optimized relative to the bar center.

TESTING PARTS

MAC® offers Eddy Current, Electromagnetic, Flux Leakage and Ultrasonic solutions for on- or off-line testing of hex, round and other dimensions. Typical parts being tested include fasteners, ball bearings, expanders and small tubular components. Parts may be submitted for a free evaluation and analysis conducted by MAC’s certified engineers to determine the best NDT option for your application.

OIL COUNTRY TUBULAR GOODS

Oil Country Tubular Goods (OCTG) are used in oil and gas production. As a rule, these include drill pipe, casing and tubing that are used both onshore and offshore. Producers of OCTG tube must meet the demands of individual client specifications, as well as API 5L & 5CT, ISO, EN and other standards.

NODULARITY INSPECTION

As the use of nodular graphite iron material has expanded in recent years for cast automotive safety parts, ultrasonic velocity measurement is providing a reliable, industry accepted means of verifying material integrity.

TESTING HIGH PERFORMANCE NITINOL WIRE

Magnetic Analysis Corporation has introduced an eddy current test for detecting cracks and inclusions in Nitinol wire. Surgical applications such as stents and heart valves, where the wire's ability to be deformed at one temperature during insertion, and then recover its original, undeformed shape when heated above its "transformation temperature" after exposure to typical body temperatures of 98.6°F (37°C), is essential.

MULTI-TEST SYSTEM FOR AUTOMOTIVE SHOCK ABSORBER TUBING & OCTG

Magnetic Analysis Corp. has supplied a combined ultrasonic/eddy current test system to inspect cold drawn welded tube to be used in manufacturing shock absorbers at a new plant in Monterrey, Mexico, built by Prosankin, formerly known as A-4C-Sankin. The plant’s focus is production and sales of cold drawn tubes primarily for automotive use, although the test system is also designed to provide the future capability of meeting API 5CT testing requirement for oil country tubular goods (OCTG).

MEDICAL TUBE AND WIRE

As NDT techniques have expanded, so have the applications which now encompass many critical products that are being used where it is extremely difficult and expensive to replace or repair, or where failure can cause serious and life threatening consequences.

HEAT EXCHANGER TUBE

These types of tubes are commonly found in heat exchangers used in oil refineries and for other large chemical processes, power generation and many other high liability, high down time cost applications. Many of these situations are also high pressure applications.

FINNED TUBE

Metallic inclusions in copper tubing can be caused by two major sources. The first comes from the material itself which can contain residual impurities from continuous casting. The second, and major source of metallic inclusions in finned copper tubes, occurs during the manufacturing process. Inclusions that are the results of the manufacturing process can appear in the tube when the tool used to make the fins is breaking.

FERRITIC INCLUSIONS IN NON-FERRITIC TUBE, BAR AND WIRE

Inclusions are small particles or linear ferrite residuals that are usually considered to be undesirable. They may be spherical or elongated. They may originate from two major sources.

ECHOMAC® ULTRASONIC SYSTEMS FOR ERW TESTING

Magnetic Analysis Corp.’s line of Echomac® systems for testing ERW tube during production now includes Phased Array ultrasonic models as well as conventional ultrasonic systems.

ECCENTRICITY INSPECTION

Eccentricity, where the OD and ID of a tube are not concentric, is a problem that is most often created during extrusion of the tube from billet. Eccentricity in the finished product can mean wall thicknesses that don’t meet specifications, causing problems during further processing downstream. The Echomac® FD, 4 Channel is an ultrasonic equipment used for detecting eccentricity.

DETECTING SIGMA PHASE

Sigma Phase is a brittle, nonmagnetic phase of tetragonal structure occurring in many transition metal alloys. It is frequently encountered in high chromium stainless steels. The test consists of a two channel MultiMac® eddy current tester. One channel is used for the detection of typical defects, while the other absolute channel is used for finding Sigma Phase.

MAC® Is Celebrating Its 95th Anniversary

Operating on an international scale, MAC assists metal manufacturers the world over in meeting demands and specifications that require multiple technologies. With the support of our subsidiaries and field engineering network, the company is proud to serve customers throughout the Americas, Europe, Scandinavia, Eastern Europe, India, Korea, China and Australia.

William S. Gould, 3rd in Memoriam

Bill Gould succeeded his father as President of Magnetic Analysis Corp. (MAC) in 1964 and remained in that role until 2007, a remarkable 42 year run in which he successfully built MAC from a small, U.S. oriented eddy current testing company into a global leader in eddy current, ultrasonic and flux leakage equipment and services. Bill remained Chairman until his death and was honored as a fifty year member of the American Society for Nondestructive Testing in 2016.

For Immediate Release March 1, 2022

Magnetic Analysis Corporation, (MAC®) a designer and producer of nondestructive test instruments and systems since 1928, is pleased to announce the asset acquisition of TacTic™, a Division of Laboratory Testing Inc. (LTI), effective February 28, 2022.