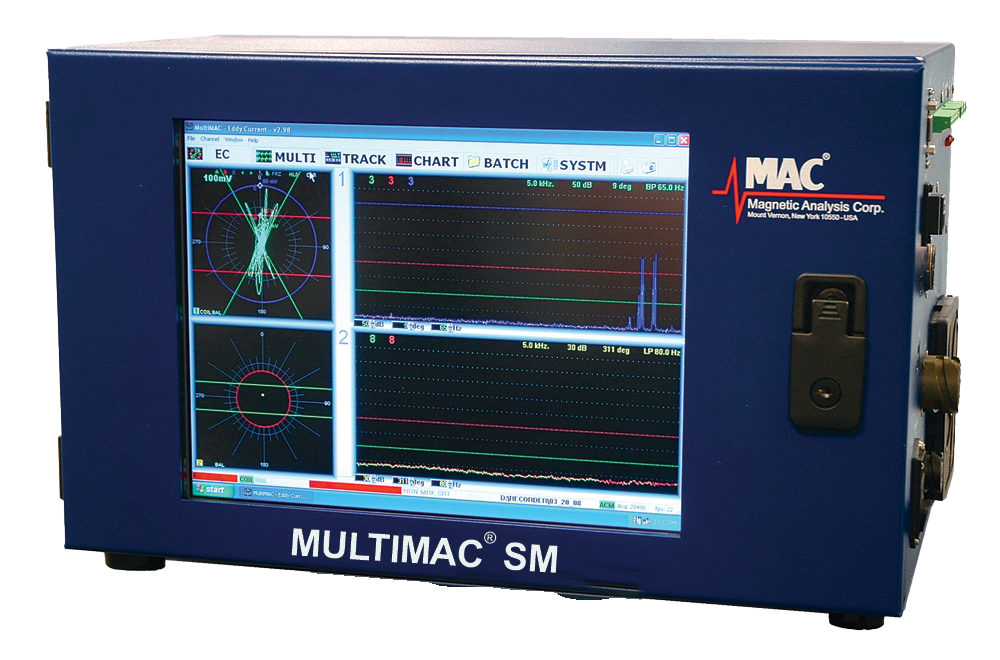

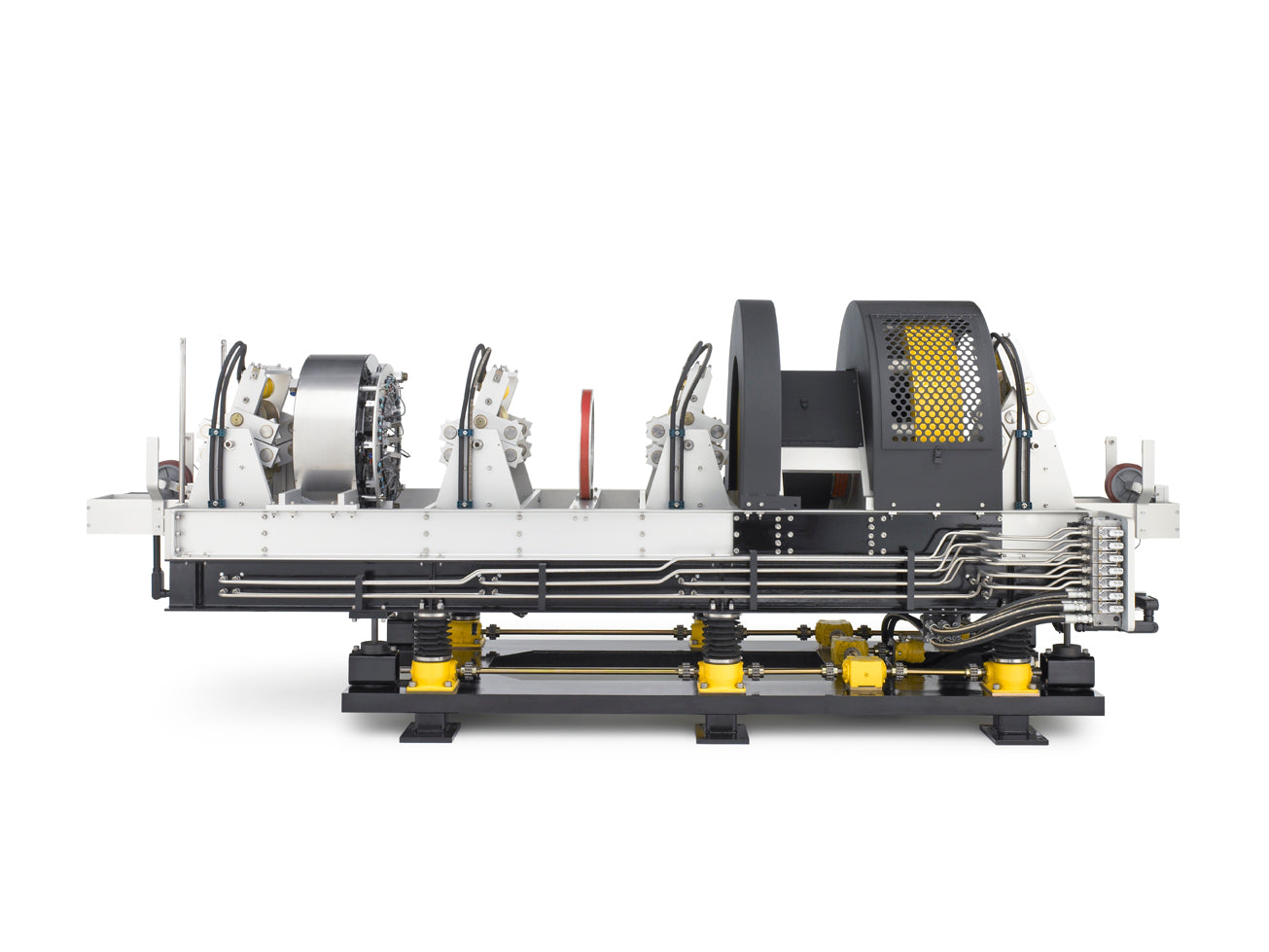

Transverse & Longitudinal Rotoflux® 500mm Multi-Channel System

Applications

- MFL test methods are used for the detection of outer surface, inner surface and subsurface discontinuities in magnetic steel tubular products of uniform cross section, such as seamless and welded tubing.

- Flux leakage technology can also be used for inspecting ferrous parts, and products such as wire rope, sucker rods and coupling stock.

- When properly applied, MFL can detect the presence and location of significant longitudinally or transversely oriented discontinuities such as pits, scabs, slivers, gouges, roll-ins, laps, seams, cracks, holes and improper welds.

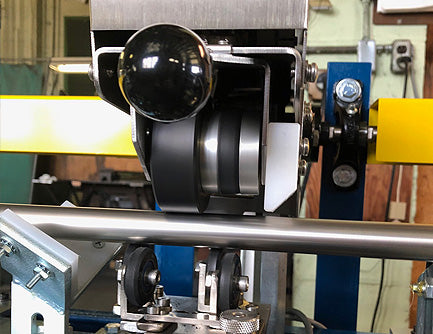

14″ Pipe Recording, Transverse Defect Detection