User Configured Grading of Rod & Wire Segments or Coils During Production

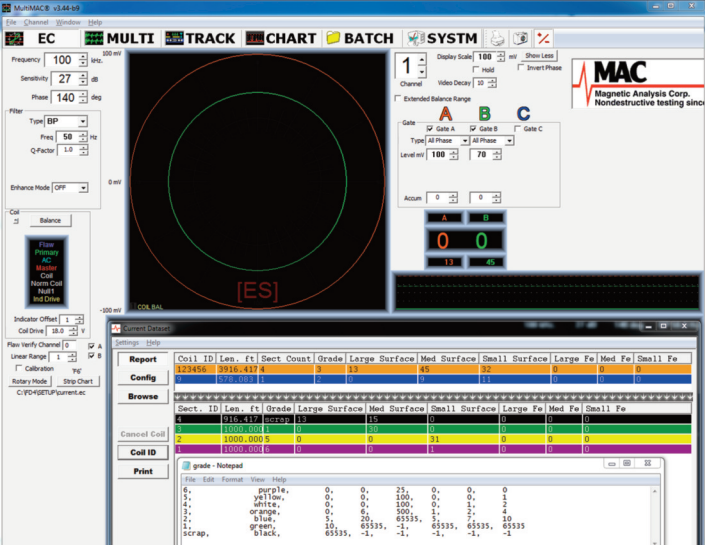

MAC’s Grading Software option provides a convenient, efficient means of automatically categorizing the quality level of individual segments and entire coils of metal wire, rod and bar during production. Using the Multimac® or Minimac® 55 eddy current instrument, the customer can customize the defect types, each based on a specific threshold gate, specify the maximum number of defects for each grade level, and configure reports. Surface defects as well as inclusions are detected and categorized.

- Use with Multimac® or Minimac® 55 eddy current testers.

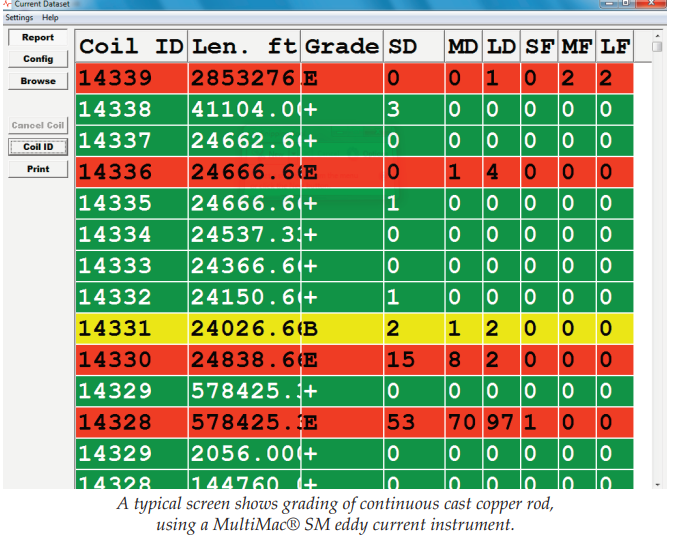

- Characterize the product based on the number and type of surface defects and inclusions in a given segment or coil.

- Customer specifies the maximum number, type of defect signals, and a color code for each grade level.

- Each type of defect is detected by a specific gate in the instrument, and is counted in a separate counter (up to 24).

- At the end of a shift or day, the grade data for each coil tested can be reported.

- Each coil can be tagged with a unique coil ID and grade.

- Section length can be defined in metric or english mode.

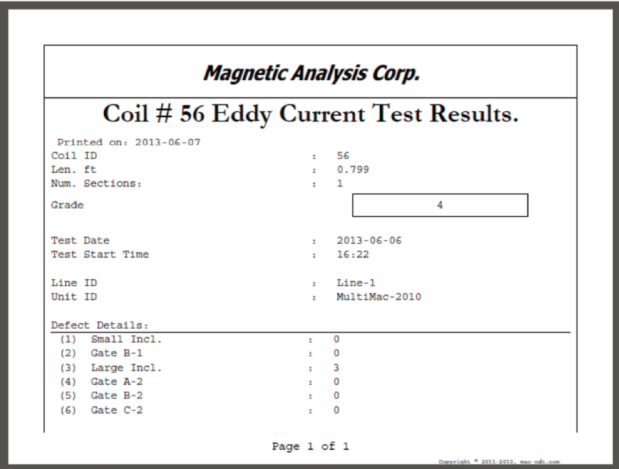

- Reports including coil ID, grade, date, time, production line, test instrument, and total defect count for each designated type are provided in a CSV file, easily interfaced with customer databases. Multilingual support is available.

- Automatically print a simple Coil Report Label after completion of each coil test.

- Manually print customer selected data, such as coils tested during the current shift, configuration, number, grade and type of defects found.

You may also like

Economic, Single or Two Channel Full Feature Digital Eddy Current Tester for Tube, Bar, Wire

Eddy Current Instrument for Encircling Coil, Sector and Rotary Probe Testing of Tube, Bar, & Wire