Inspection Features:

- 100% test coverage with high throughput rates.

- Handles tube and bar ranging from 5 to 25mm diameter.

- Test wall thickness as thin as 0.3mm.

- Local remote pulser/receiver allows high gain but provides low susceptibility to mill electrical interference.

- Wide band width transformer signal coupling allows for any transducer frequency selection from 5 to 17 MHz.

- Precise thickness resolution (<1 µm) and excellent repeatability and reliability.

- 8,000 RPM running speed.

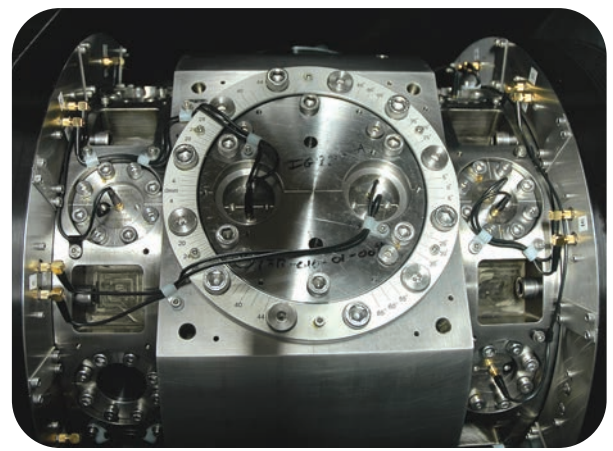

- Precision test blocks & transducer holders.

- Convenient adjustment of the transducer angle.

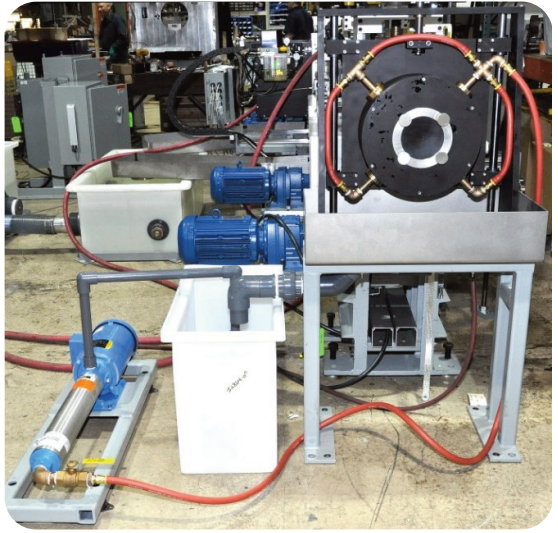

- Unique water flow control loop ensures the correct volume of water flow for coupling.

- Trouble-free upgrades where space may be limited. Tubes as short as 1 meter can be successfully tested. Use with existing instruments.

- Use with MAC’s Echomac® 6/6A instrument for critical applications

Superior Performance

- shear waves for transverse, longitudinal surface and subsurface defects.

- Store and recall an unlimited number of setups

Echomac® Electronics

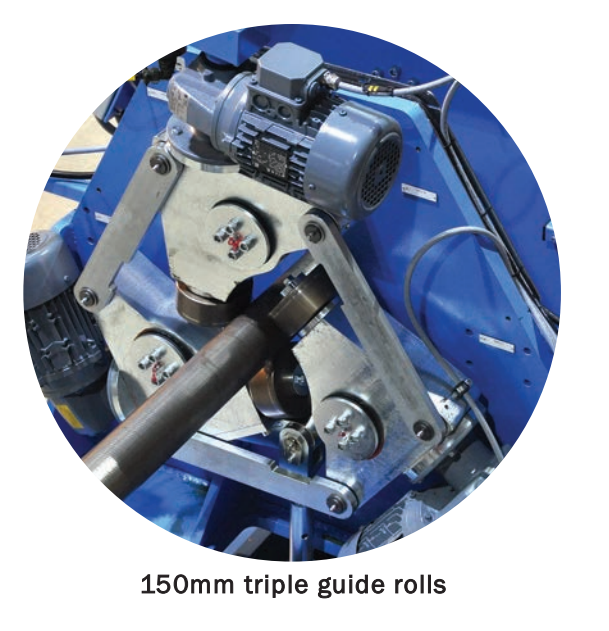

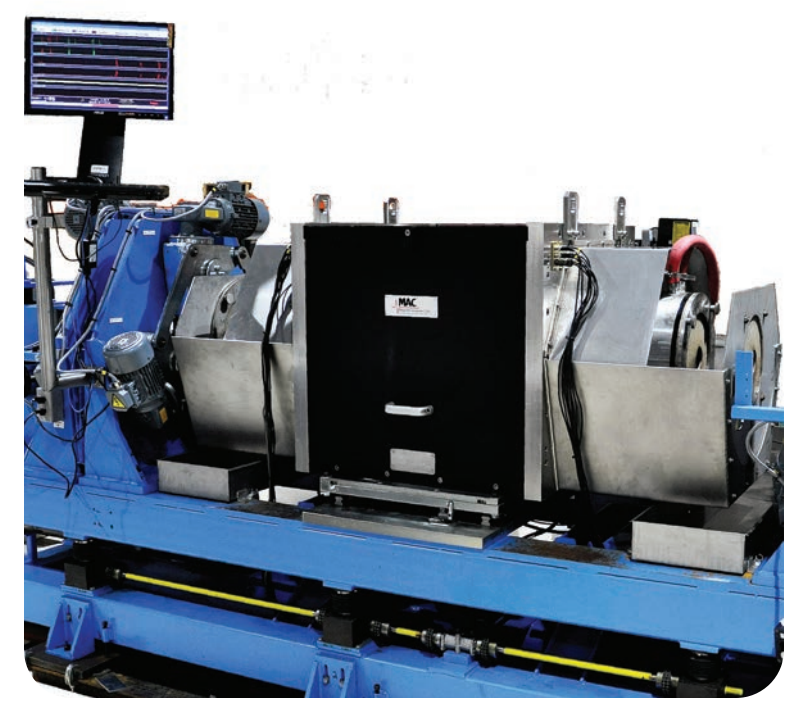

Precision Handling Mechanics

- Triple guide roll benches with one point adjustment of the table height and diameter of the 3 point drive and centering guides, for the ultimate in automation and rapid size changeovers.

- V-Roll drive benches with AC frequency controlled drive motor and top pinch rolls, plumbing for water supply and drain, and provision for vertical alignment of the UT rotary.

- Controls

- Sophisticated controls manage the water system, variable frequency drive speed of the UT rotary and the drive bench, defect marking, sorting, and data archiving.

- Optional Conductor provides comprehensive control of the entire test system, including unified tube status reporting for installations with multiple test stations.

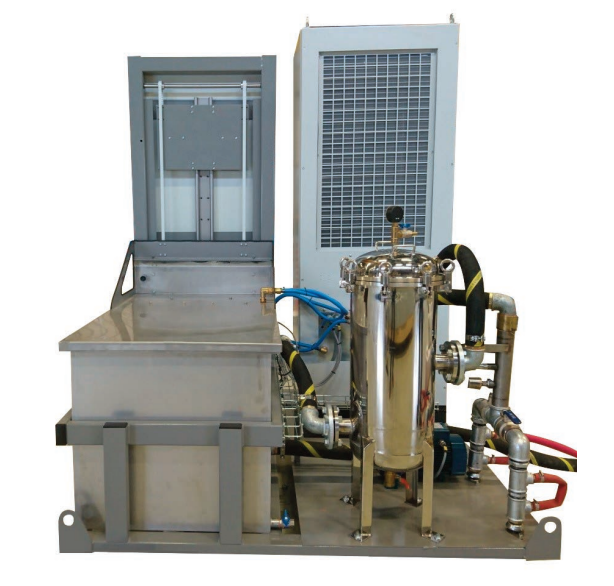

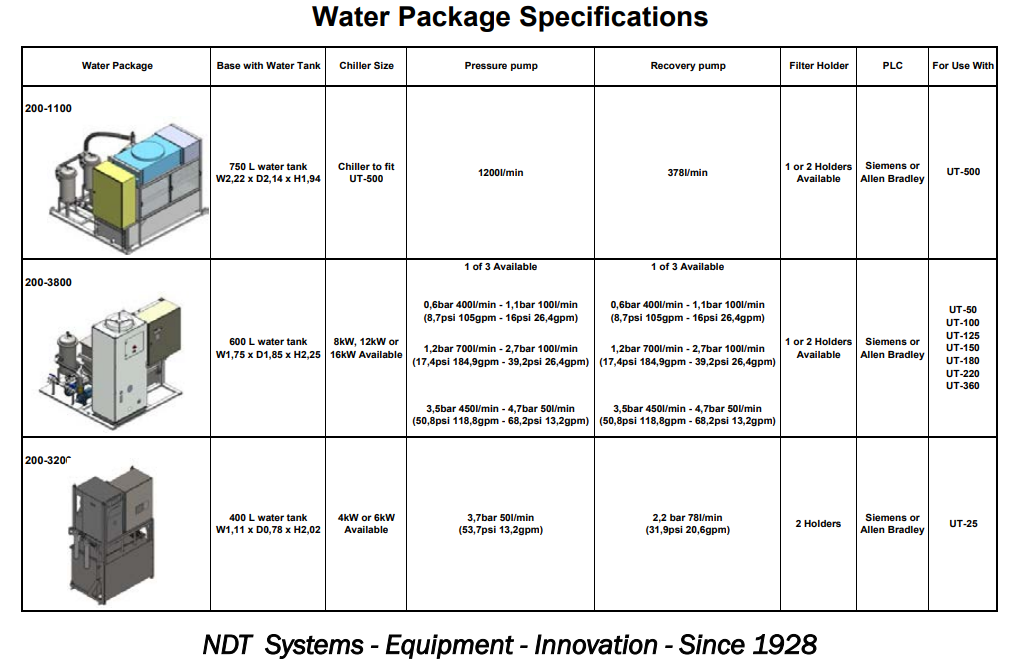

Water Packages

- Ultrasonic testing using a rotary requires clean, temperature

- controlled water to provide the couplant for transmission of the

- ultrasonic waves between the transducers and the product under

- test. MAC offers a range of recirculating water packages, sized for

- the rotary that is being used.

Rotary UT Applications

- Oil country tubular goods - test to API 5CT and 5L standards

- Seamless and welded tube

- Heat exchanger tube

- Hydraulic boiler tube

- Umbilical tube for off shore installations

- Large round billets during early stages of production

- Hot rolled bar

- Small diameter highly finished bar and wire

- Specialty steel bars

You may also like

For use with Magnetic Analysis Test Systems

Prevent False Test Signals from Contaminated Bar & Tube Surfaces & Reduce Rotary Cleaning Downtime.

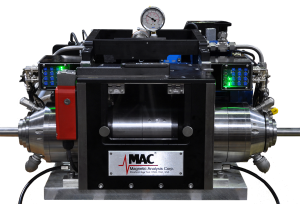

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products