Coil Platforms Provide Proper Alignment

Proper positioning of the test coil with respect to the material being tested is a key ingredient of any eddy current inspection system. The test material must be mechanically and electrically centered when it passes by or through coils and tangent (sector) type coils.

COIL PLATFORMS FOR “V” ROLL TEST BENCHES

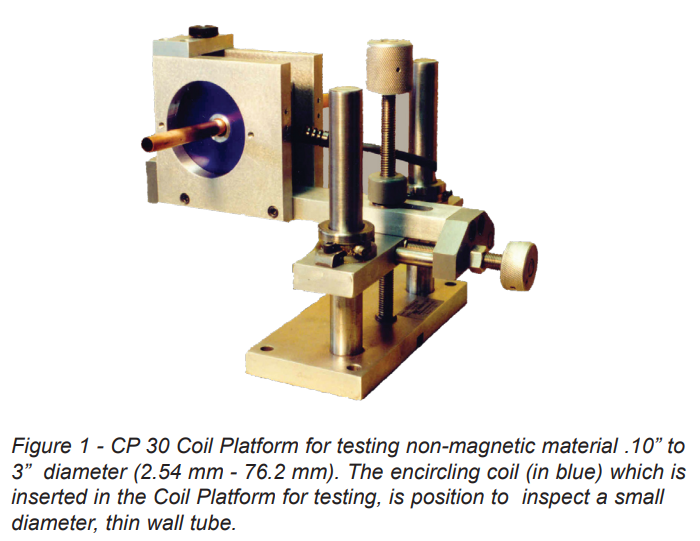

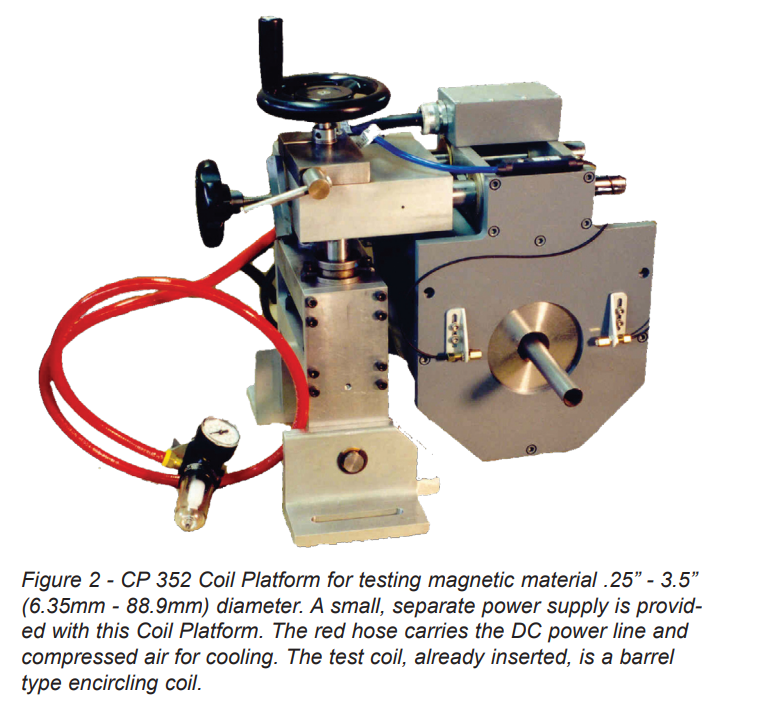

Most MAC Coil Platform Models can be adjusted vertically and horizontally to provide the proper centering. Typically, these Coil Platforms are designed to be mounted on welded “V” roll test benches. Figure 1 illustrates a typical Coil Platform for testing non magnetic material and Figure 2 shows a saturation Coil Platform for magnetic material testing.

COIL PLATFORMS FOR CONSTANT CENTER TRIPLE DRIVE BENCHES

Coil Platforms for use with constant center triple drive roll benches are also available. Because the entire bench can be adjusted up and down to align the test coils and heads with the level of the incoming test material, separate horizontal and vertical adjustments are not needed. The triple drive roll pinches also center the test material, and a “floating option” (see page 4) is available.

Saturation Coil Platforms for Testing Magnetic Material

Saturation Coil Platforms are specially designed to include a source of magnetization in order to inspect magnetic material. Most MAC saturation coil platforms incorporate a direct current encircling saturation coil such as shown in the CP 352 at right. These CP’s use a lower voltage, higher current (100 to 800 amps.) powersupply. A means of cooling, such as air or water is needed.

MAC also has saturation coil platforms that use higher voltage and lower current (1 to 5 amps.). Because of the lower current, these platforms do not need cooling.

MAC’S WIDE RANGE OF COIL PLATFORMS

- Precision engineered for MAC NDT systems

- Accurate positioning of test coils

- Test Magnetic or Non-Magnetic Material

- Models for Encircling/Segment (throughput) or Tangent (sector) coils

- Test cylindrical, square, hex, rectangular bar, wire and tube

COIL PLATFORMS WITHOUT DC SATURATION FOR NON-MAGNETIC OR MAGNETIC TUBING OR BAR

Standard Encircling Coil Platforms

Standard non saturation coil platforms are typically used for test applications such as copper, aluminum, and most stainless, where there are minimal or no permeability variations in the test material. However, some magnetic material can be tested in Standard Coil Platforms using magnet test coils.

Coil Platforms are available to mount all coil sizes and types. Molded plastic encircling test coils are easily inserted in the Coil Platform, and are available in a wide variety of types and sizes, including long life titanium lined coils. Stock sizes range from 1/8” up to 7 3/4” ID. (3.175mm - 196.85mm). MAC Coil Platforms are generally used in conjunction with MAC Drive Mechanisms designed to drive and center the material in the test coil.

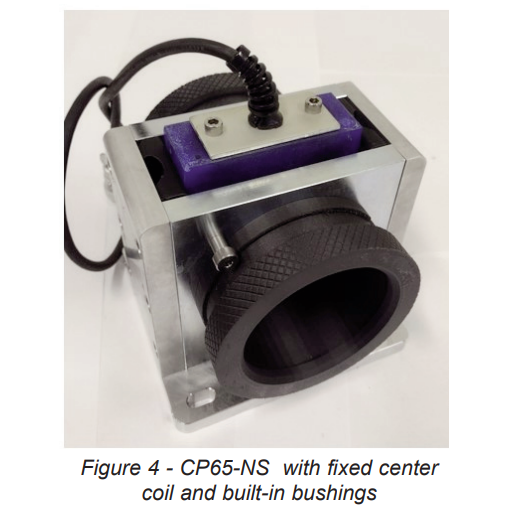

For applications such as production lines with straighteners and similar processes where a Drive Mechanism is not generally used, a Coil Platform such as the CP-65 NS (Figure 4) may be the best choice.

Fixed Center Coil Platform with Bushings

The CP 65 NS is a non saturating robust unit with a fixed center test coil and easy insert bushings on either side to stabilize the material and provide a constant center configuration during the test. All CP 65 coil platforms are designed to test tube and pipe up to 65mm (2.56”) diameter. Additional CP 65 models include:

CP 65 VNS - includes vertical adjustment.

CP 65 PM - includes permanent magnet for some saturation.

CP 65 VPM - includes vertical adjustment and permanent magnet for some saturation.

Tangent Coil Platforms

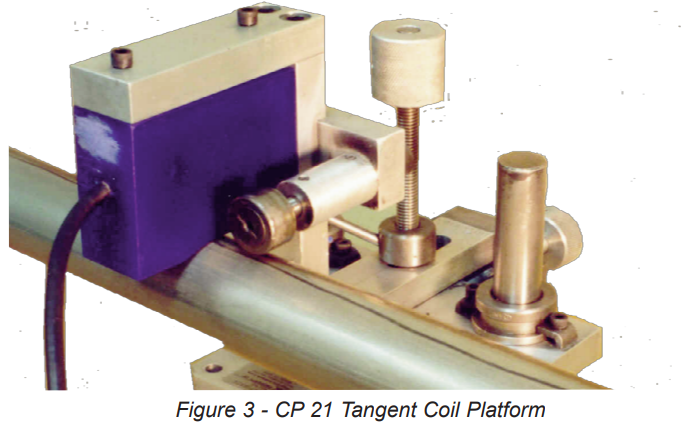

MAC has designed Coil Platforms for holding tangent (or sector) coils for some on-line applications, such as weld lines, where threading the material through a standard encircling coil is a problem and only the weld zone or a similar localized area requires inspection. Because they cover a limited test area of the tube under inspection, an improved signal-to-noise ratio may result.

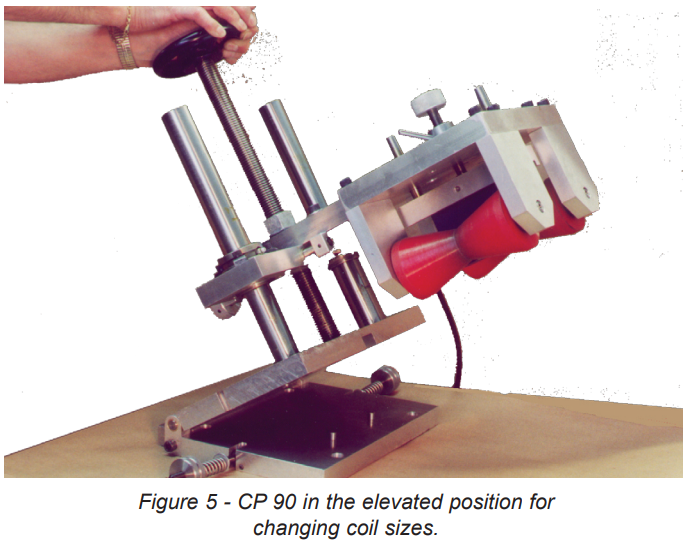

The CP21 Coil Platform (Figure 3) and CP 90 (Figure 5) are typical of non saturating coil platforms used for testing non-magnetic material. The CP 21 is shown with a tangent coil for testing a tube weld. The small guide roll helps to maintain the coil in the correct position for testing. The CP 90, is shown below in an elevated position. Changes of coil size can be conveniently handled in this position with the Coil Platform raised off of the test material. When testing, the coil platform is lowered and the guide rolls on either side of the test coil surface ride the material, thus maintaining the proper positioning.

Direct Current saturation is required to inspect ferromagnetic material that contains permeability variations. MAC DC Coil Platforms incorporate suitable DC saturation as part of the Coil Platform design. The saturation reduces the permeability variations in the test material that would otherwise interfere with the eddy current test.

Typically, DC saturation is required on carbon steel, certain grades of stainless and even cupro nickel, where permeability variations can develop from cold working the material.

The Series 352 Platform, shown in Figure 2, page 1, is typical of those DC platforms that are air cooled and come supplied with a low voltage, DC power supply for the saturation coil system. This CP is suitable for testing thin and medium wall carbon steel tubing and surface inspection of bar stock, and utilizes a barrel type encircling coil, inserted in the coil platform.

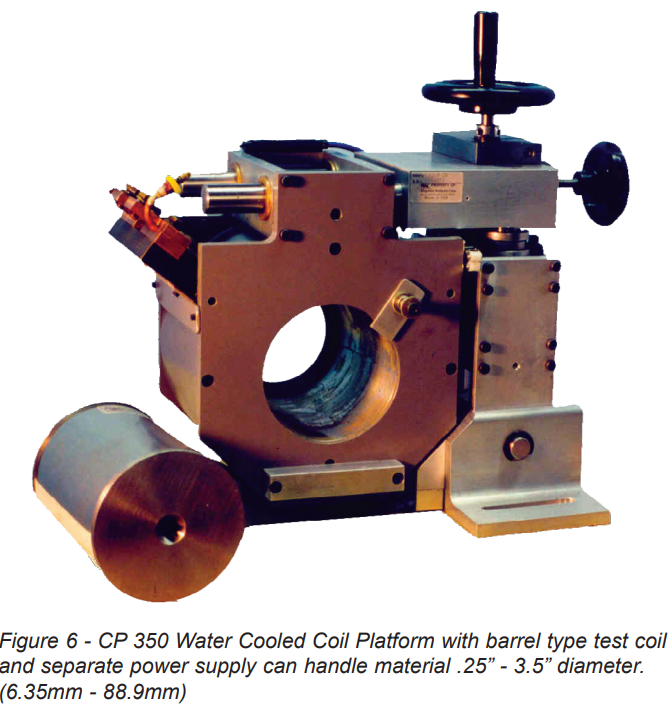

Water cooling is utilized for more powerful, larger size, saturation Coil Platforms such as the CP 350, (Figure 6) and CP 500 (not shown) which might be used on heavier wall tubing, for example. These heavy duty Coil Platforms also require stronger solid state power supplies which are not included in the CP package and must be ordered separately. The 65/125/225 mm Coil Platforms, however, (see page 4) do not require water cooling because they use high voltage, low current for saturation.

For light wall, smaller diameter tube or bar, a magnet type test coil, such as a model 65 PM can be used instead of the barrel type. The magnet test coil uses a permanent magnet to provide the necessary field for testing. Usually, these coils are used on thin wall material up to 1-1/2” (38.1 mm) diameter, however, the 65 PM can handle material up to 2.56” (65mm)

Tangent Coil Platforms for Magnetic Material

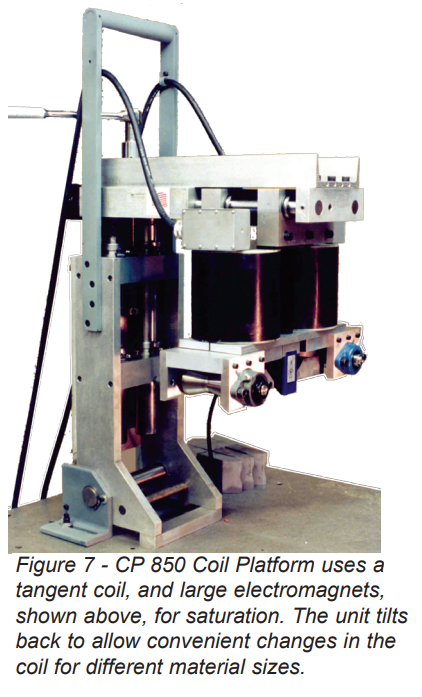

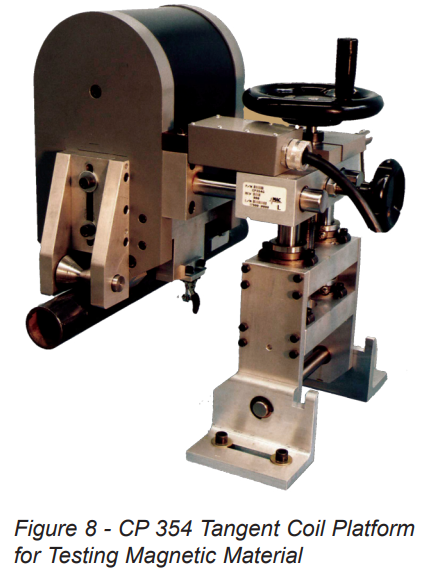

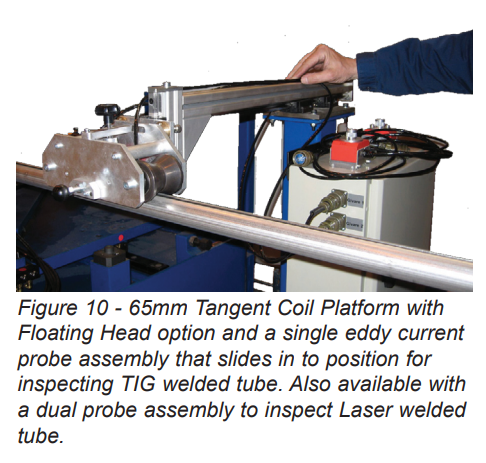

When tangent coils are used on large diameter or heavy wall magnetic material, special Coil Platforms such as the CP 850 (Figure 7) or the CP 354 (Figure 8) are used. Both platforms have large electromagnet saturation capability. A tangent Coil Platform with floating head is also available.(see Figure 10, page 4).

Slide and Elevate Platforms

Larger, heavier duty Coil Platforms are often mounted on a Slide and Elevate Platform to allow the unit to be raised, lowered, and moved horizontally to center the test coil accurately around the test material.

Slide and Elevate Platforms are also needed where a 65/125/or 225 mm CP is used with a “V” roll drive welded test bench. Since the 65/125/225 mm CPs do not include built-in horizontal and vertical adjustments, the Slide and Elevate Platform provides the positional adjustment needed.to center the coil with respect to the test material size and location.

ENCIRCLING, SEGMENT & TANGENT COIL PLATFORMS WITH SATURATION FOR MAGNETIC OR NONMAGNETIC MATERIAL

FLOATING HEAD OPTION

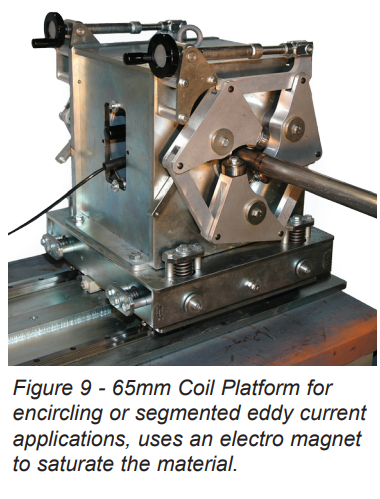

By using a floating head option, the 65/125/225 coil platforms can follow the movement of the tube or bar under test. This feature is useful for tube weld mills and bar and wire drawing benches The 65mm Coil Platform shown in figure 9 uses an electro-magnet to saturate the material and can use standard or segmented encircling coils on magnetic and non-magnetic material. Segmented coils are recommended for larger diameters above 100 mm. Other Coil Platform sizes of this type include the 125 and 225mm.

where the material under test tends to move around. These Coil Platforms are usually mounted on constant center triple drive roll benches which provide the needed adjustments of the Coil Platform for the test material size and location.

TANGENT CP

An advanced tangent weld inspection system shown in figure 10, can include the floating head option to inspect TIG and Laser welded tube. This tangent coil system can detect small pin-holes, typically 0.2 mm in diameter, which are usually impossible to find using standard tangent coils.

| TABLE 1 - TYPICAL TEST COILS & COIL PLATFORMS | ||

|---|---|---|

| Description | Size Ranges | Coil Platforms |

|

STANDARD NULL ENCLRICLING COIL SERIES - FOR INSPECTING NON-MAGNETIC MATERIALXES/ XJS/ XMI Series are typical Null Encircling Coils for flaw detection. They come in a broad range of sizes and types |

0.10” - 7.5” (2.54 - 190.5mm) | 30, 31, 34, 60, 65NS/VNS |

|

STANDARD NULL ENCLRICLING MAGNET COIL SERIES FOR INSPECTING SMALL DIAMETER, THIN WALL MAGNETIC MATERIAL XES/ XJM/ XIM and XJX/ XBI Series are Encircling Coils which provide moderate saturation suited for small diameter and thin wall magnetic material testing |

0.1875” - 6” (4.76 - 152.4mm) | 30, 60, 65PM/VPM, 125, 225 |

|

BARREL COIL SERIES - FOR INSPECTING MAGNETIC MATERIAL XJF/XLF Series Barrel Coils are inserted in the Coil Platform’s Air or Water Cooled DC saturation coil so that permeability differences in magnetic material are minimized to allow accurate eddy current testing. Water cooled DC saturation coils generally require a High Current Power Supply that is not included in the Coil Platform price and must be ordered separately as optional equipment |

0.1” - 9.25” (2.54 - 235mm) | 350, 352, 353, 500, 600, 750, 900 |

|

TANGENT COIL SERIES - FOR INSPECTING SECTORS IN NON-MAGNETIC MATERIALXYA/XYB Series are typically used on welded steel or stainless tube to inspect the weld zone. |

1.0” - 9” (25.4 - 228.6mm) | 21, 90 |

|

TANGENT COIL SERIES - FOR INSPECTING SECTORS IN MAGNETIC MATERIAL XYA/XYB - Series are typically used on welded steel or stainless tube to inspect the weld zone |

0.5” - 12” (12.7 - 304.8mm) | 354, 850 |

|

ENCLRICLING/SEGMENT COIL SERIES - FOR INSPECTING MAGNETIC OR NON-MAGNETIC MATERIAL XES encircling non segment, & SEG segment coils are most used for larger diameters above 100 mm. |

65mm - 225mm | 65, 125, 225 |

|

STANDARD ABSOLUTE ENCLRICLING COIL SERIES - DUAL COILS FOR COMPARATORS XPC/XVM series are absolute coils that are supplied in pairs to allow “comparison” between test material and a known acceptable piece. |

0.5” - 6.5” (25.4 - 152.4mm) | 33, 35, 63 |

Additional sizes of Coils and Coil Platforms are available including more than 50 specialized types of test coil designs. Variations include coils with different internal spacing, overall width, or number of windings, sizes, and shapes, all designed to produce optimum results for specific applications. MAC’s experienced Engineers can help select the most appropriate coil and coil platform for specific test needs.

You may also like

Demagnetizers permit efficient, continuous elimination of unwanted magnetism in ferrous rod, wire, bar and tubing