For Calibrating Eddy Current Test Instruments

The object of the calibration procedure is to establish an acceptable quality level for a given lot of non-magnetic tubing or bar stock. Eddy current instruments are limited without a precise means of assuring the user of the exact nature or magnitude of the defect being indicated.

Therefore, it has been necessary to machine or drill an artificial defect on a sample of the material to be inspected. This defect had to be carefully calculated and machined to correspond to a minimum acceptable quality level.

Now the calibrating operation is done quickly and easily without any time consuming machine shop operations. The tool itself is simple to use, compact and light-weight at approximately 1.5 lbs. A fitted case is provided for storing it. Due to its portability, this tool is also advantageously used for field inspections to set up a quality standard at a customer plant before the material is shipped. The notching tool offers a simple means of mechanically creating a reproducible, controlled defect for comparison purposes.

The calibration notches most often required in establishing standards for stainless steel, copper, brass, or aluminum bar stock and tubing range between .003” and .015” in depth.

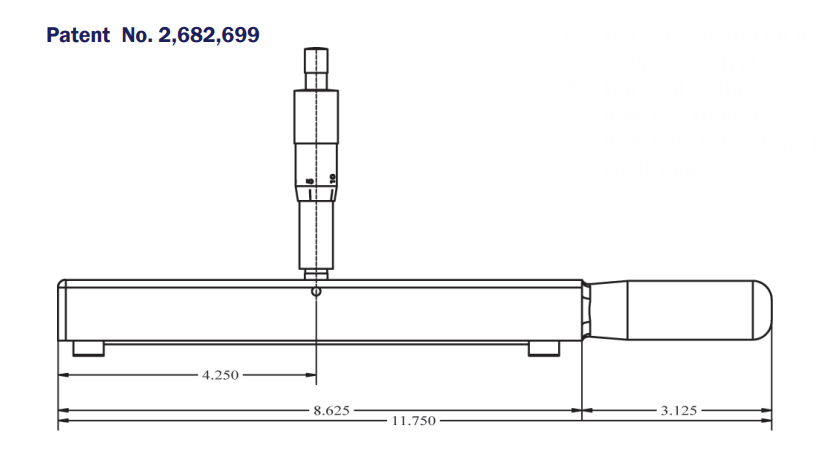

The notching tool was designed to prevent any incidental abrasion or marking of the surface of the material being notched. Two nylon bearing surfaces, placed on either side of the 0.25” round file, accomplish this purpose. The file holder is designed so that the file may be removed easily for cleaning or replacement.

The micrometer, affixed to the upper surface of the file holder, flexes the file beyond the nylon bearing surfaces, to any desired degree. To provide one or a series of notches with it, the operator would proceed in the following manner:

Patent No. 2,682,699

- The micrometer on the tool is set for the desired depth of cut

- The tool is then placed on the material so that it is transverse to the guide and so that one side of the tool butts against the guide end

- The tool is moved back and forth across the material in a straight sawing motion without any rocking or twisting

- This motion is continued until the tool moves freely

- At this point the file has cut a notch of the pre-selected depth

The Eddy Current Instrument is now set up to test the material and its sensitivity adjusted to indicate the presence of the notch. A specified quality level is now established for testing the remaining material.