To Cut Notches For Calibrating Ultrasonic & Eddy

Current Test Instruments

Portable, Time-Saving Tool for Cutting Precision Notches in Pipe and Bar

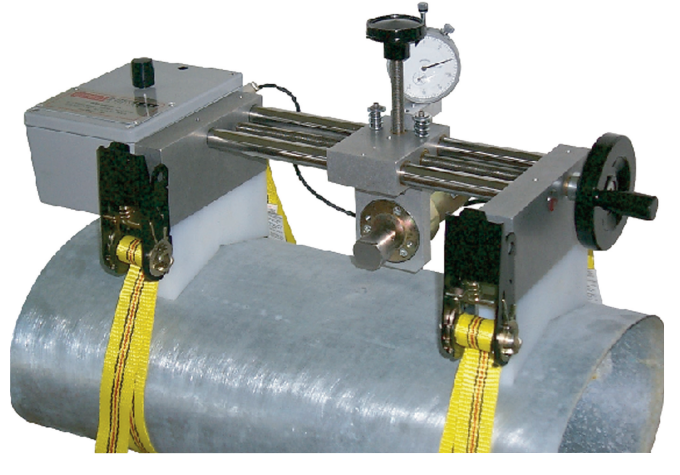

The MicroBite TNC-1000 powered notching tool is a portable tool designed to cut precision test calibration notches on the OD of pipe and bar. It uses a 2” blade to cut straight notches up to 9” long and as deep as 0.5” with 0.001” accuracy.

MicroBite Features

- Powered drive spins the 2” diameter blade.

- Cut notches up to 9” long and as deep as 0.5”.

- Maintains desired depth with 0.0010” accuracy.

- Convenient knob and readout for blade depth adjustment.

- Supplied with tungsten Saw Blade 2"OD x .500"ID x .006" Thk 36 teeth.

- Blade widths available: 0.006”, 0.008” 0.010”, 0.014”, 0.020” and 0.025”.

- Blades interchange easily.

- Handles stock ranging from 1” - 24” diameter.

- Works on most common metals and alloys.

- High-speed/high-torque motor

For accurate nondestructive tests on tube and bar stock, a calibration procedure is used to establish an acceptable quality level for a given lot of material. An artificial defect on a sample of the material to be inspected is machined or drilled. This defect has to be carefully calculated and machined to correspond to a minimum acceptable quality level.

To cut precision EC calibration notches in pipe and bar stock:

Saw operates dry; do not use cutting oil.

• Strap MicroBite securely to pipe or bar stock measuring 1” to 24” in outer diameter.

• Zero blade against pipe surface.

• Adjust blade speed knob using knob.

• With blade spinning, turn depth screw until integral micrometer shows desired depth.

• Advance blade with hand crank.