MAC’s Bar Wash Systems

When contaminants such as rust, steel chips, debris, and rolled in scale accumulate on a test product’s surface, false test signals can occur.

A Bar Wash unit lowers the number of false signals, reduces downtime for cleaning out rotaries, bearings or other affected parts, and cuts down on the amount of scrap from false signals, especially if the test is running automatically.

Applications

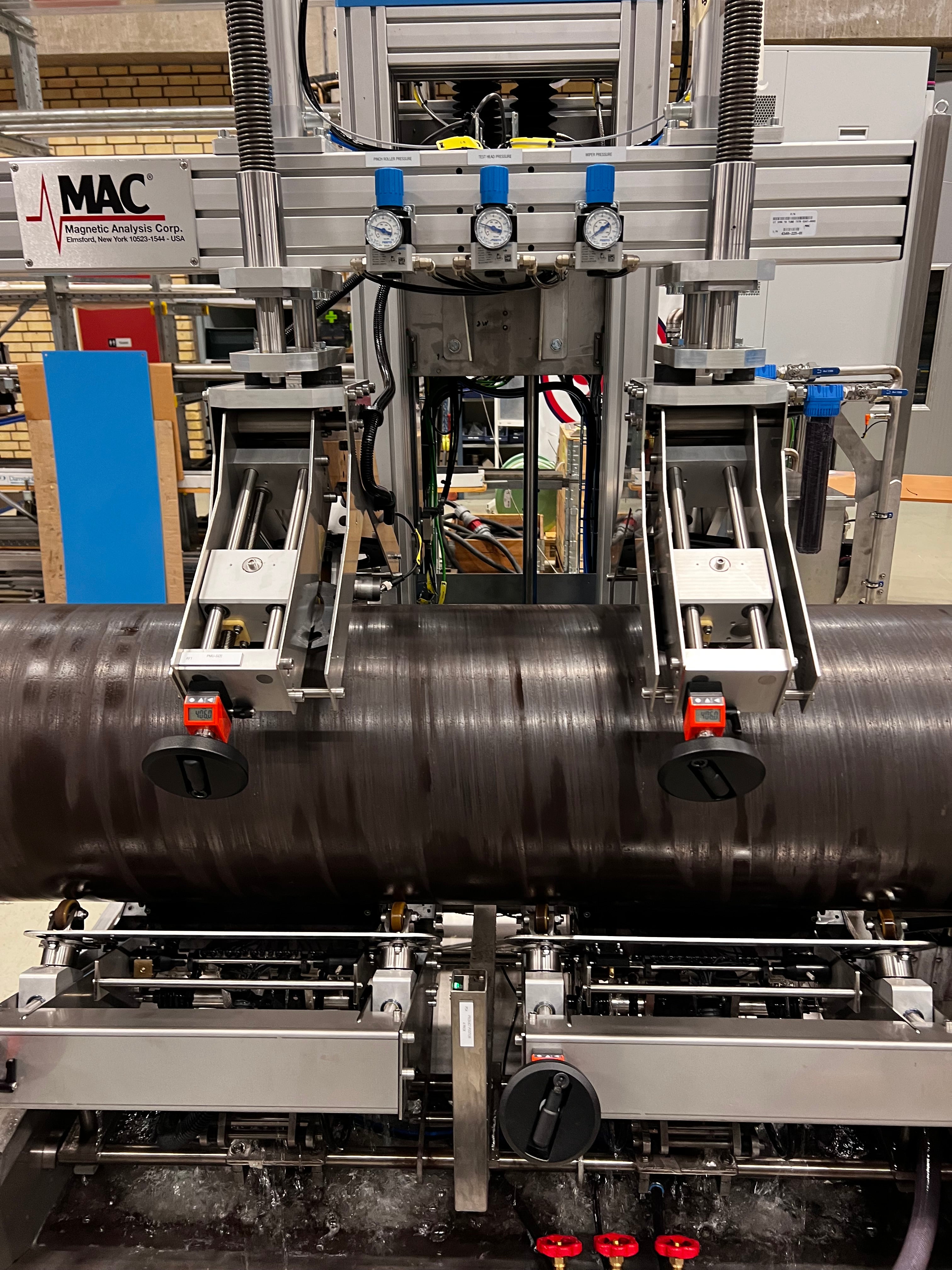

- Rotary ultrasonic test systems where debris in the water medium interferes with the test results and can also cake up the ultrasonic transducers.

- Rotary eddy current test systems where noise signals can occur when testing hot rolled bars that have rolled-in scale on their surface.

- Customer’s existing ultrasonic test systems such as ROWA.

- Installations where fluid from bar straighteners need to be cleaned off before going through an eddy current or ultrasonic rotary.

- Bars or bundles of bars with rust from having been left outside.

- Use with Echomac® UT and Rotomac® EC system rotaries

Description

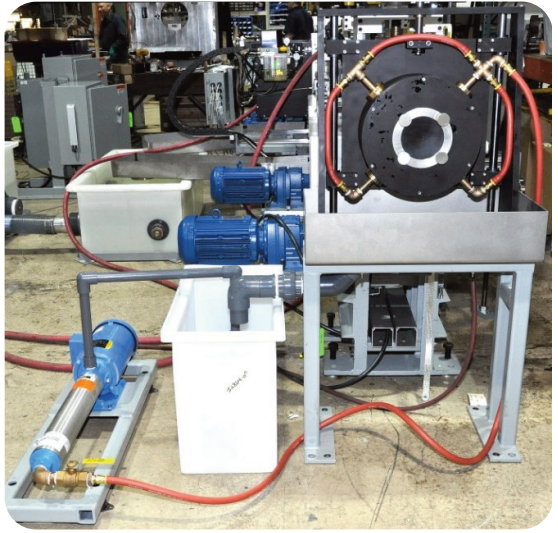

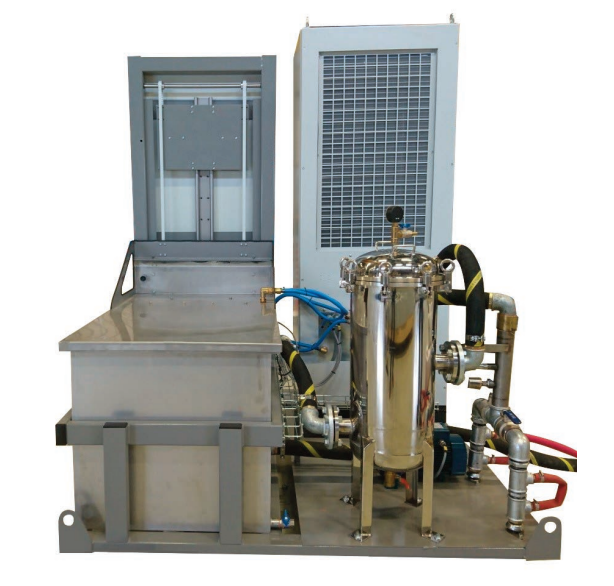

- A closed loop recycling water system.

- Bar wash spray head with 4 air nozzles.

- 200 psi water pressure pump

- 22 gallon stainless steel catch basin.

- Settling tank to collect large particles, where

needed. - Return tank

- Starter/disconnect control panel

- Current models can handle up to 0.5”or up to 5” (12.7mm or 127mm) diameter. Other sizes may be available upon request.

Advantages

- Reduce false test signals.

- Decrease downtime for cleaning out test rotaries, bearings or other affected parts.

- Reduce scrap from false reject signals

You may also like

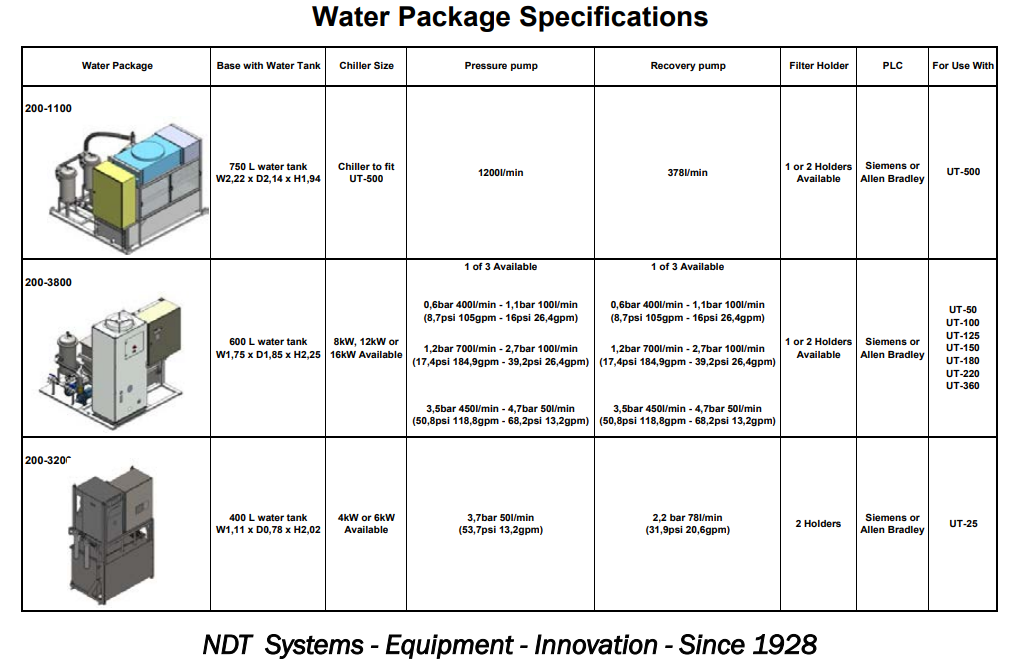

WATER PACKAGE

For use with Magnetic Analysis Test Systems

SPIN THE TUBE TEST

Spin-The-Tube systems for testing product used for transporting gases and fluids in oil, gas and mining operations.

ECHOMAC® FULL BODY TESTER

Ultrasonic Spin-the-Tube Inspection System with APC Pitch Control Technology