- Staffed with knowledgeable, fully ASNT certified Level II and III engineers.

- Several test lines are equipped to handle material from 0.100” (2.54mm) OD to 3.5” (88.9mm) OD at lengths of 24 feet (7.6 metres) and higher, depending on the application and defects to be detected.

- The facility can accurately detect a wide range of defects in carbon steel, stainless & specialty steel, copper and aluminum tube or bar.

- An overhead crane allows us to handle full truck loads of material, thus making it possible to inspect up to thousands of feet of material per day.

- Turn-around time is usually within one week, with faster times available provided advance notification is given.

Our Products

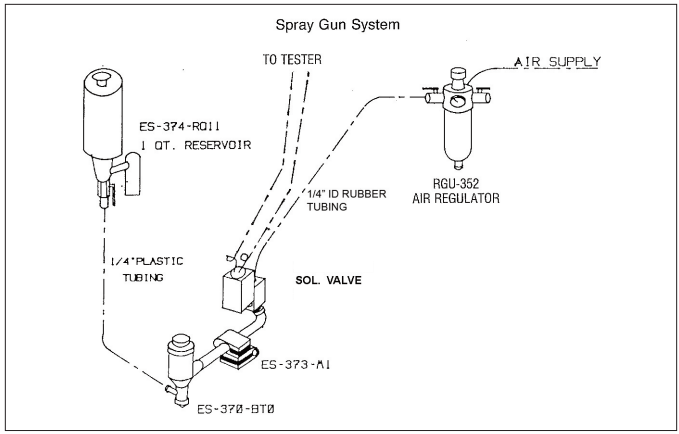

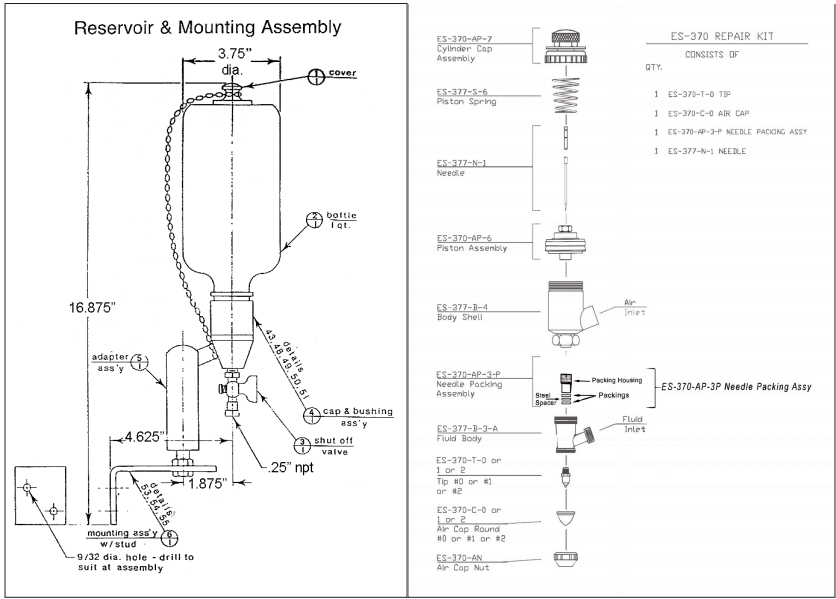

AUTOMATIC MARKER

The Model 800 spray marker is designed for use with MAC inspection systems. W

7RT CABLE ASSEMBLY

SKU: RT7CBL

Engineered for durability and consistent signal/power transmission, these cables are compatible with a wide range of NDT equipment. They are built to withstand the stresses of industrial use while maintaining reliable performance in various testing environments.

75mm UT Rotary

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

CABLE ADAPT,XESST MED/LG COIL SOLD

SKU: CBL1068 MAN

Engineered for durability and consistent signal/power transmission, these cables are compatible with a wide range of NDT equipment. They are built to withstand the stresses of industrial use while maintaining reliable performance in various testing environments.

130MM ROTOFLUX® AC

Flux Leakage Tester for Detecting Surface Defects in Hot Rolled Black Steel Bar

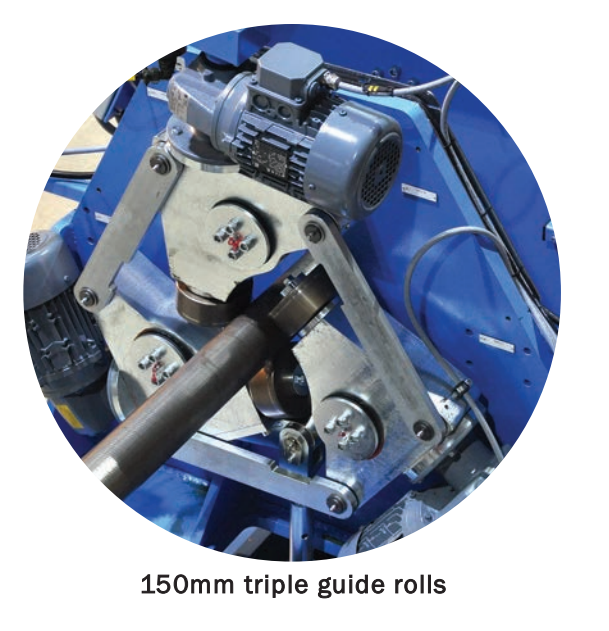

150mm UT Rotary

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products