At Magnetic Analysis Corporation, we understand the importance of precision and reliability in testing tube and pipe products. Our Spin-the-Tube systems, integrated with ultrasonic and/or magnetic flux leakage technologies, are one of our comprehensive solutions for detecting a wide range of defects and conditions in tube and pipe products.

Whether it's detecting longitudinal and transverse flaws, measuring, wall thickness, identifying lamination, or testing through-drilled holes, our systems deliver reliable performance for the integrity of your products.

Three Spin the Tube system options:

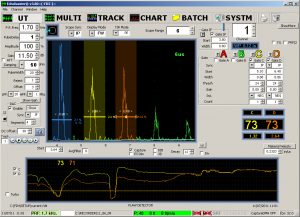

Using Echomac® FD6 Technology

For Flaw Detection, Thickness & Dimensional Measurement in Tube & Bar

- Versatile Ultrasonic tester with superior performance and versatile, intuitive operation.

- For full inspection of tubes, pipes and bars, plate and weld.

- Operate on or off line

- Upgrade and/or replace older ultrasonic testers

- Use with rotary, spin-the-tube, squirter and bubbler installations.

You may also like

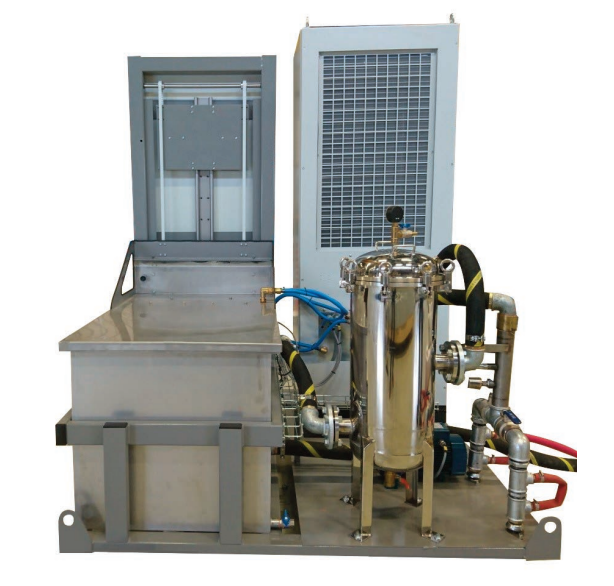

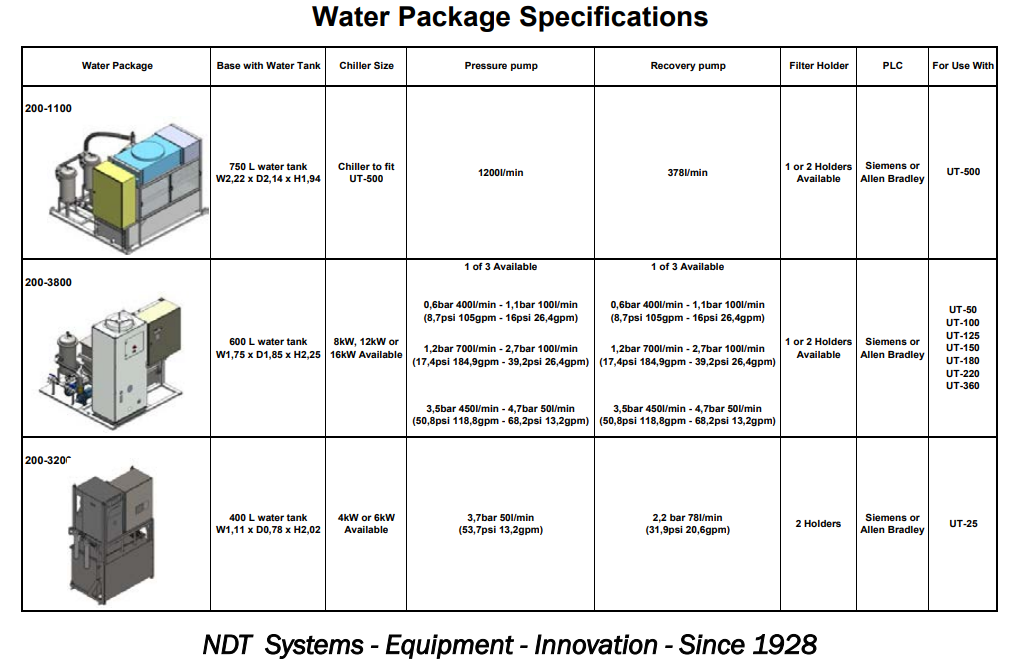

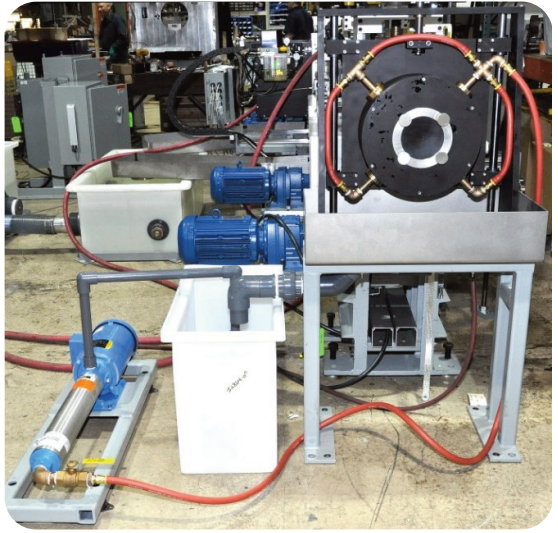

WATER PACKAGE

For use with Magnetic Analysis Test Systems

MAC BAR WASH

Prevent False Test Signals from Contaminated Bar & Tube Surfaces & Reduce Rotary Cleaning Downtime.

ECHOMAC® FULL BODY TESTER

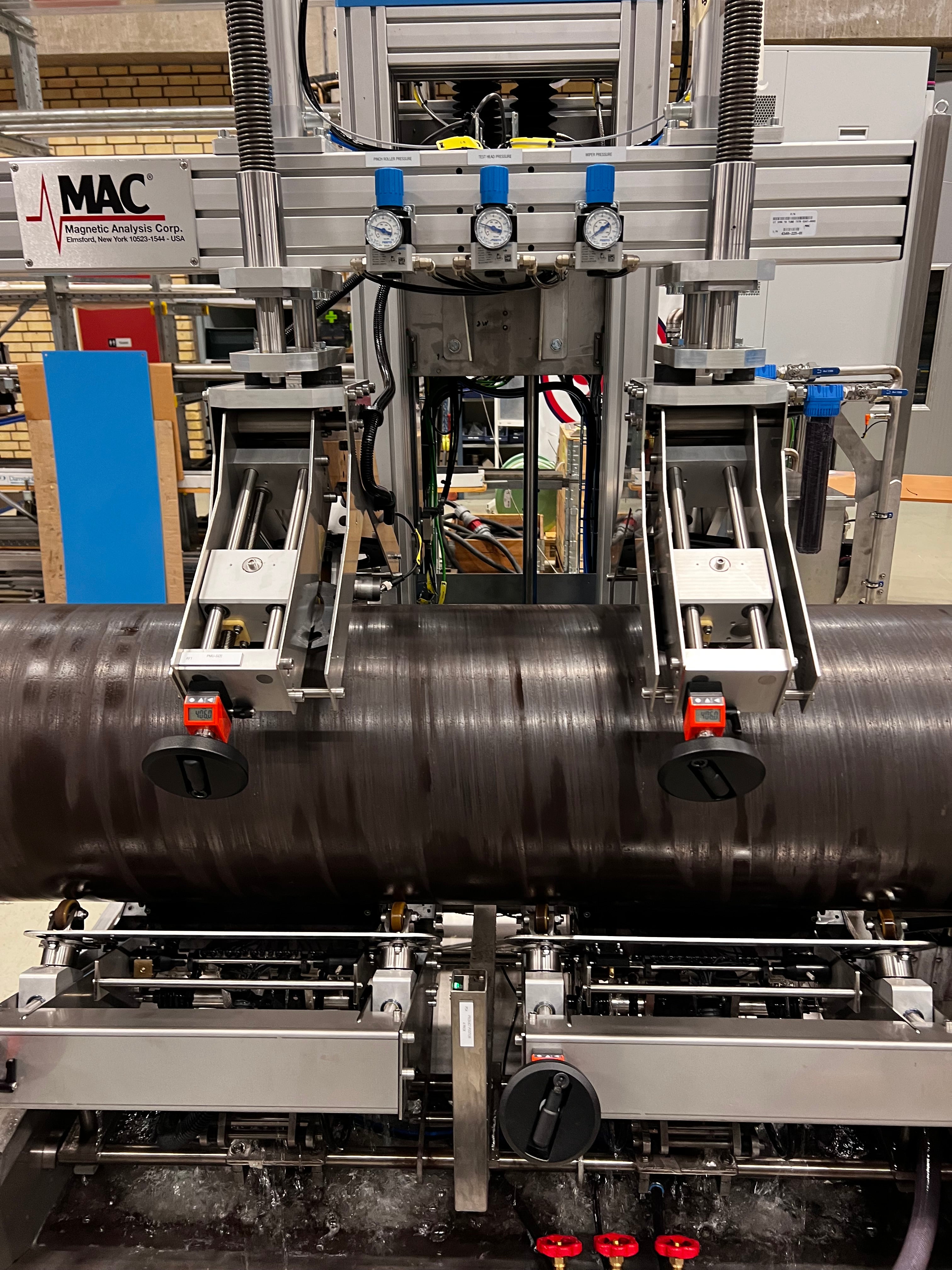

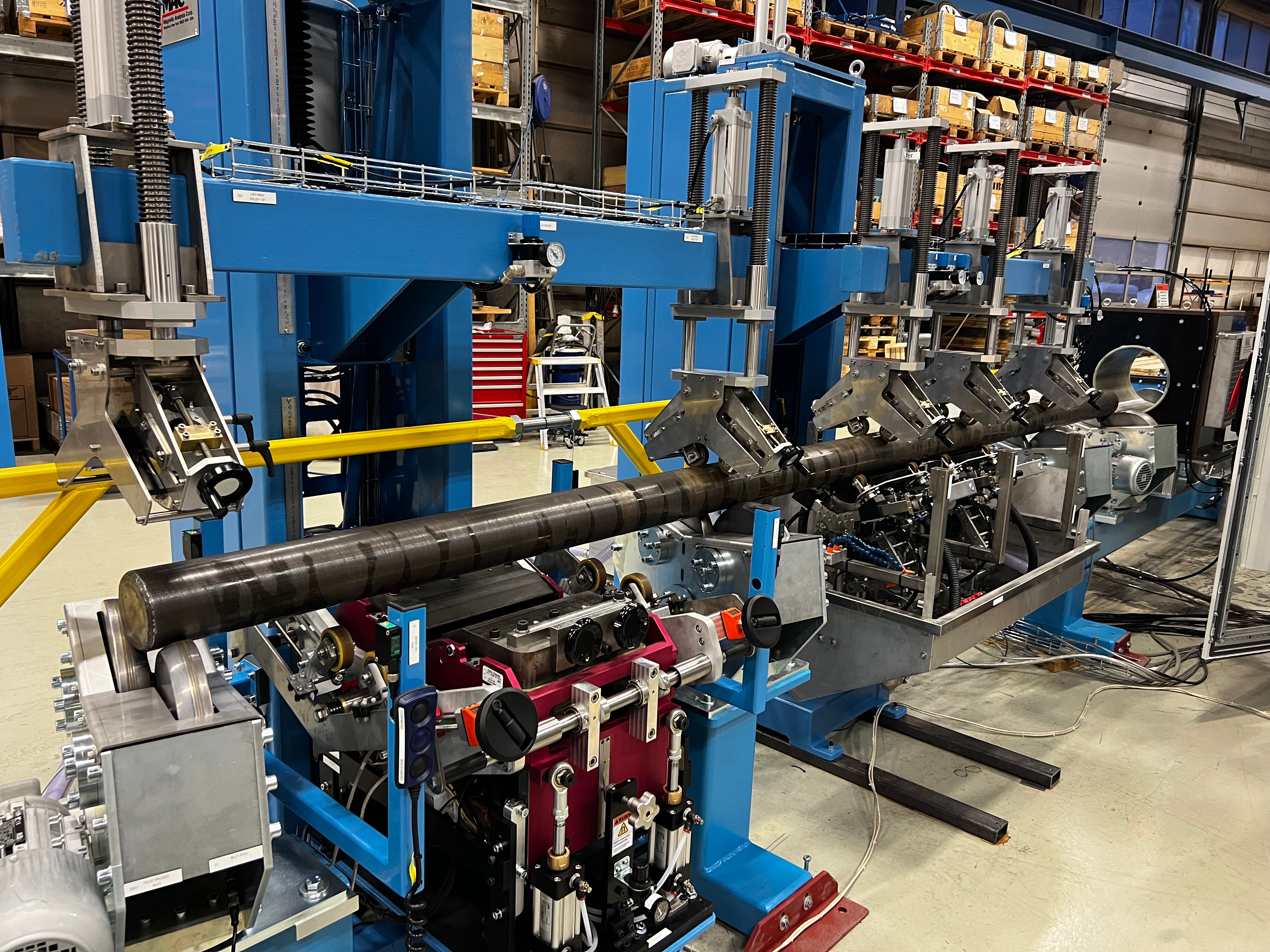

Ultrasonic Spin-the-Tube Inspection System with APC Pitch Control Technology

ECHOMAC® FD6 MULTICHANNEL UT

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar