Inspection Features

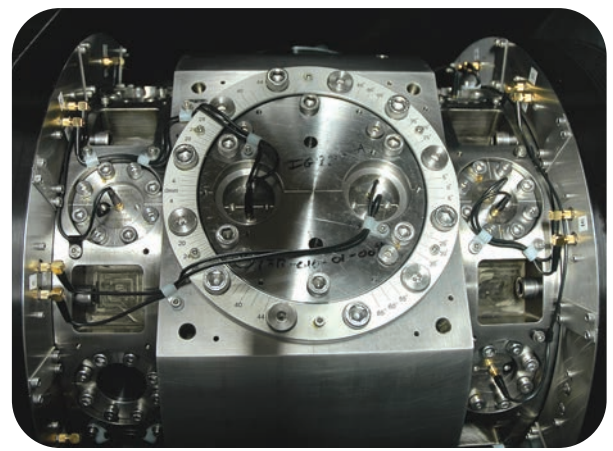

- Size Range 40-220mm (1.5" - 8.6")

- Maximum RPM 850

- Maximum Active Transducers 16 - 32

Superior Performance

- 100% Coverage at high throughput rates.

- 5mm to 500mm diameter models available.

- Multiplex transducer design allows lower noise signals and up to 48 transducer elements.

- Unique rotary mounted transformer and pulser/receivers provide maximum sensitivity and minimum noise.

- Multiple transducer elements can simultaneously test in different directions such as CW, CCW, FWD, REV, as well as measure wall thickness and detect laminations.

- Acid resistant stainless steel is used for all components that come in contact with water.

- Precision test blocks and transducer holders ensure accurate positioning to detect small defects, even at high throughput speeds.

- Seal-less rotaries reduce likelihood of damage from grit and other mill contaminants.

Versatile, Intuitive Operation

- Set up multiple tests quickly and accurately for:

- shear waves for transverse, longitudinal surface and subsurface defects.

- compression waves to detect internal defects and measure wall thickness, OD and ID. - Reconfigure transducers for different diameter material with simple rotational adjustment of the transducer offset.

- Quick access knobs for bushing and diaphragm changes.

- Store and recall an unlimited number of setups

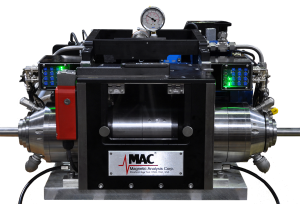

Echomac® Electronics

MAC’s Echomac FD series instruments operating with a UT rotary provide optimum performance. Together, they make up a complete system to test, analyze and control the

inspection operation.

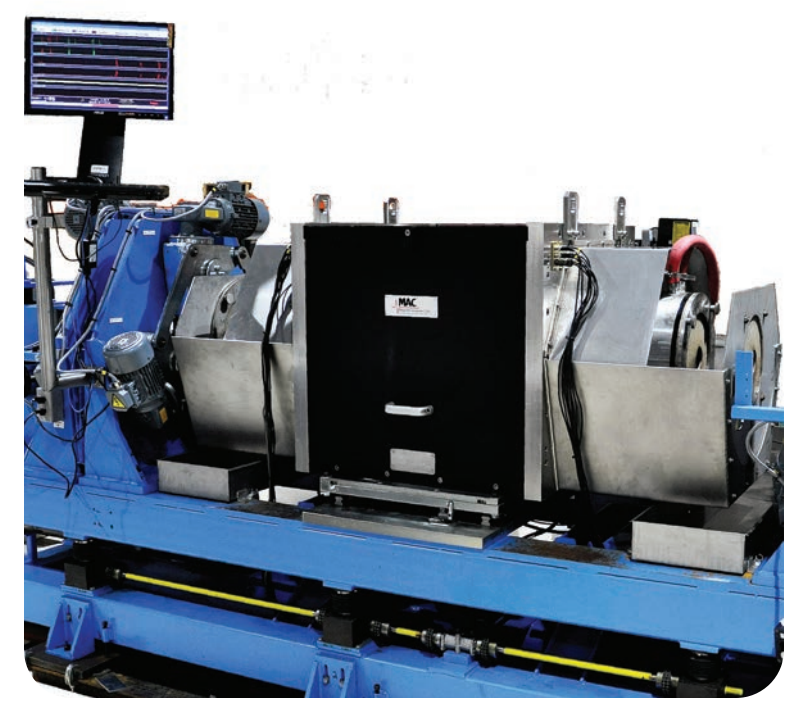

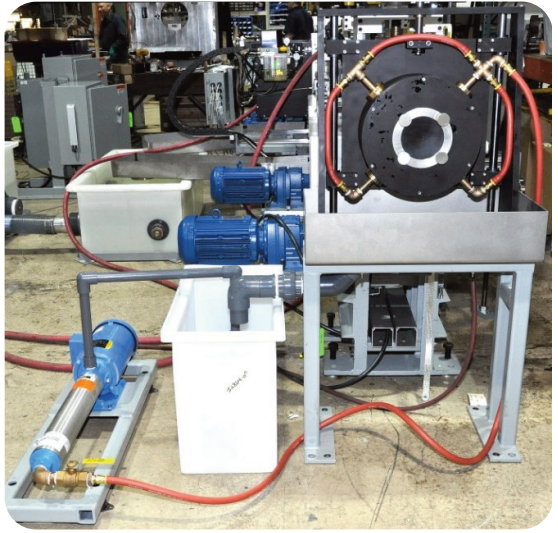

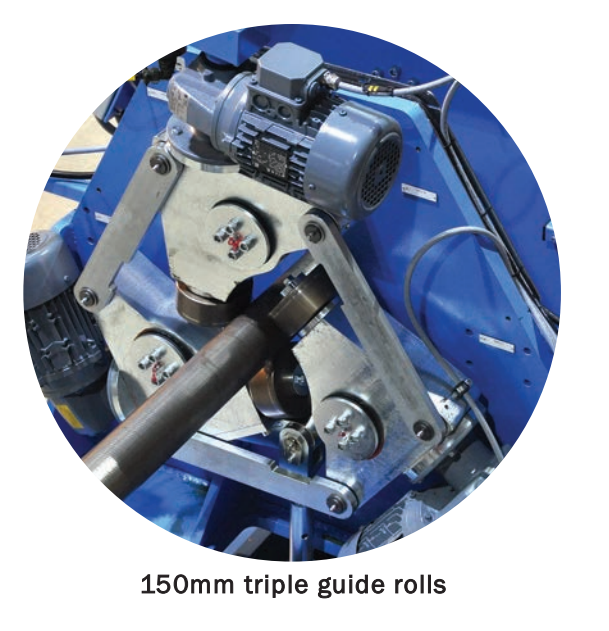

Precision Handling Mechanics

To achieve consistently accurate test results, precision mechanics are needed for proper centering, stability, and consistent speed of the tube or bar passing through the rotary. MAC can provide the right mechanics for the best system to fit your needs and budget:

- Triple guide roll benches with one point adjustment of the table height and diameter of the 3 point drive and centering guides, for the ultimate in automation

and rapid size changeovers. - V-Roll drive benches with AC frequency controlled drive motor and top pinch rolls, plumbing for water supply and drain, and provision for vertical alignment of the UT rotary.

Controls

Sophisticated controls manage the water system, variable frequency drive speed of the UT rotary and the drive bench, defect marking, sorting, and data archiving.

Optional Conductor provides comprehensive control of the entire test system, including unified tube status reporting for installations with multiple test stations.

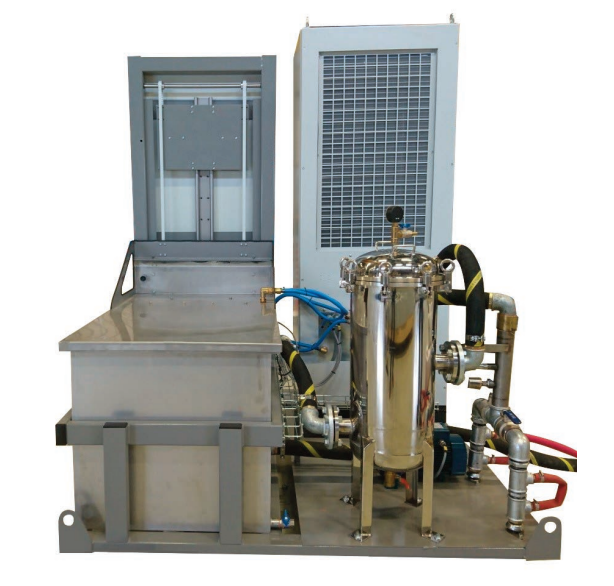

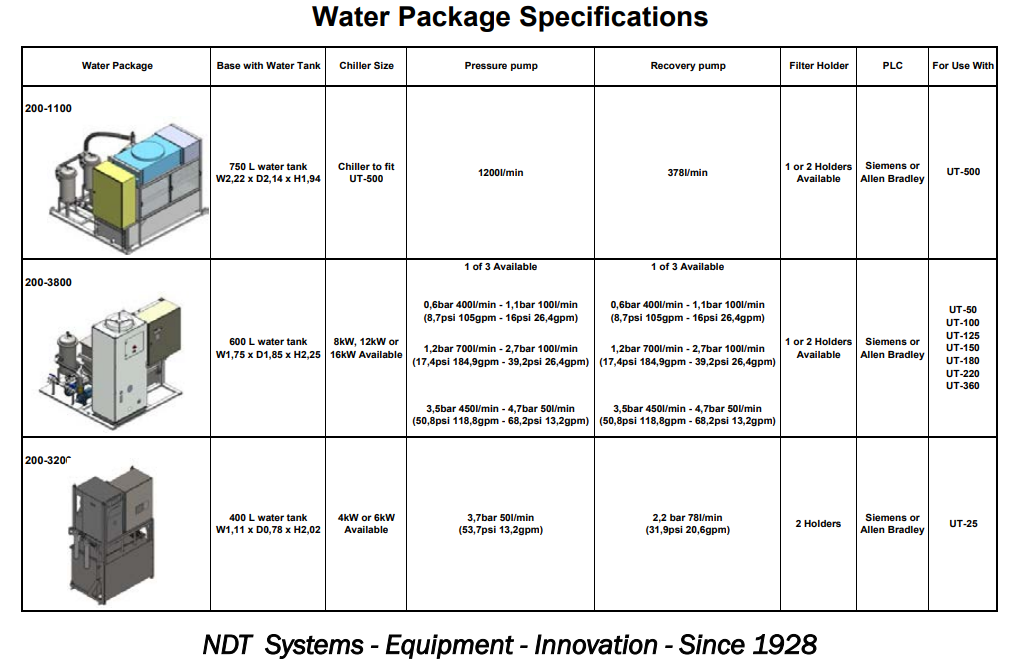

Water Packages

Ultrasonic testing using a rotary requires clean, temperature

controlled water to provide the couplant for transmission of the

ultrasonic waves between the transducers and the product under

test. MAC offers a range of recirculating water packages, sized for

the rotary that is being used.

Rotary UT Applications

- Oil country tubular goods - test to API 5CT and 5L standards

- Seamless and welded tube

- Heat exchanger tube

- Hydraulic boiler tube

- Umbilical tube for off shore installations

- Large round billets during early stages of production

- Hot rolled bar

- Small diameter highly finished bar and wire

- Specialty steel bars

You may also like

For use with Magnetic Analysis Test Systems

Prevent False Test Signals from Contaminated Bar & Tube Surfaces & Reduce Rotary Cleaning Downtime.

For Inspecting High Precision Small Diameter Tube & Bar

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products