Features:

- Handles material size changes with just one knob to adjust the roll separation, using the convenient diameter scale.

- Detects longitudinal and transverse defects, wall thickness and lamination to the 5% and 10% level in tube. Also detects inclusions in bar.

- Tests materials with ovality, and ones that are not as straight as is usually required by other test systems.

- Can be seamlessly installed into an existing production line, whether new or an upgrade of an older unit.

- Eliminates the need to adjust transducers for different tube or bar diameters.

- Ensures that sound entry point and incident angles remain constant for any material size.

- Can be configured for 5-direction capability.

- Uses multiple UT element arrays and/or discrete elements, depending on test specifications.

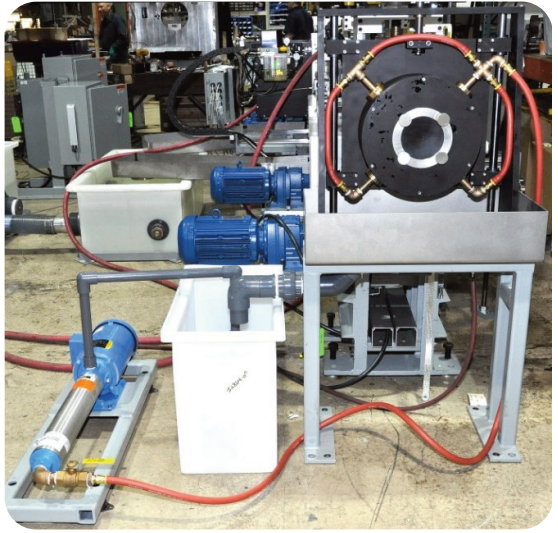

- Includes premium grade precision conveyor, designed from the perspective of nondestructive testing (NDT) for spinning tube or bar applications.

At the heart of the Echomac® Full Body Tester for Ultrasonic (UT) Testing of Spinning Tube and Bar is the unique Adaptive Pitch Control (APC) transducer carrier and the precision design “Spin-The-Tube/Bar” conveyor.

With the use of a simple dial-in pitch controller, the operator can set a precise angle of helical pitch for the conveyor’s rotation of the tube/bar. The conveyor spins the material longitudinally past the ultrasonic transducers at the correct pitch, and the APC follower rolls automatically adapt to this angle.

- Versatile Ultrasonic Inspection system can be applied to tube, pipe and bar-stock applications.

- Precision conveyor with powered roller heads automatically calculates and maintains helical pitch of inspection.

- Multi-channel Test Head Assembly with easy one-knob adjustment for different diameters.

- Tolerates materials with lack of straightness.

- Material diameters between 50mm and 355mm (2”-14”) without changing bushings or glands.

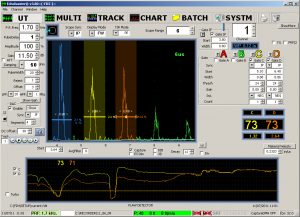

- Uses familiar Echomac® FD electronics.

You may also like

For use with Magnetic Analysis Test Systems

Prevent False Test Signals from Contaminated Bar & Tube Surfaces & Reduce Rotary Cleaning Downtime.

Model 76E “Standard Duty” Testers feature tanks with an inside length from 6″ to 30″ (150-760 mm).

“Heavy Duty” Testers are powered either by a 7.5 HP motor (76F) or by a 10 HP motor (76G).

Ultrasonic Inspection Systems for Flat-Sided Material Squares, Rectangles, Hexagonals, Strip

These rugged conveyor sections are placed at each end of a tester to provide good support for incoming and outgoing pieces.

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar

MAC's modular design Feed Systems provide mechanical handling of bars and tubing as they enter and leave a test station.