Assesses Nodularity in Ductile Iron Cast Automotive Components

- Ultrasonic velocity measurement provides an industry accepted, reliable means of testing the integrity of automotive parts.

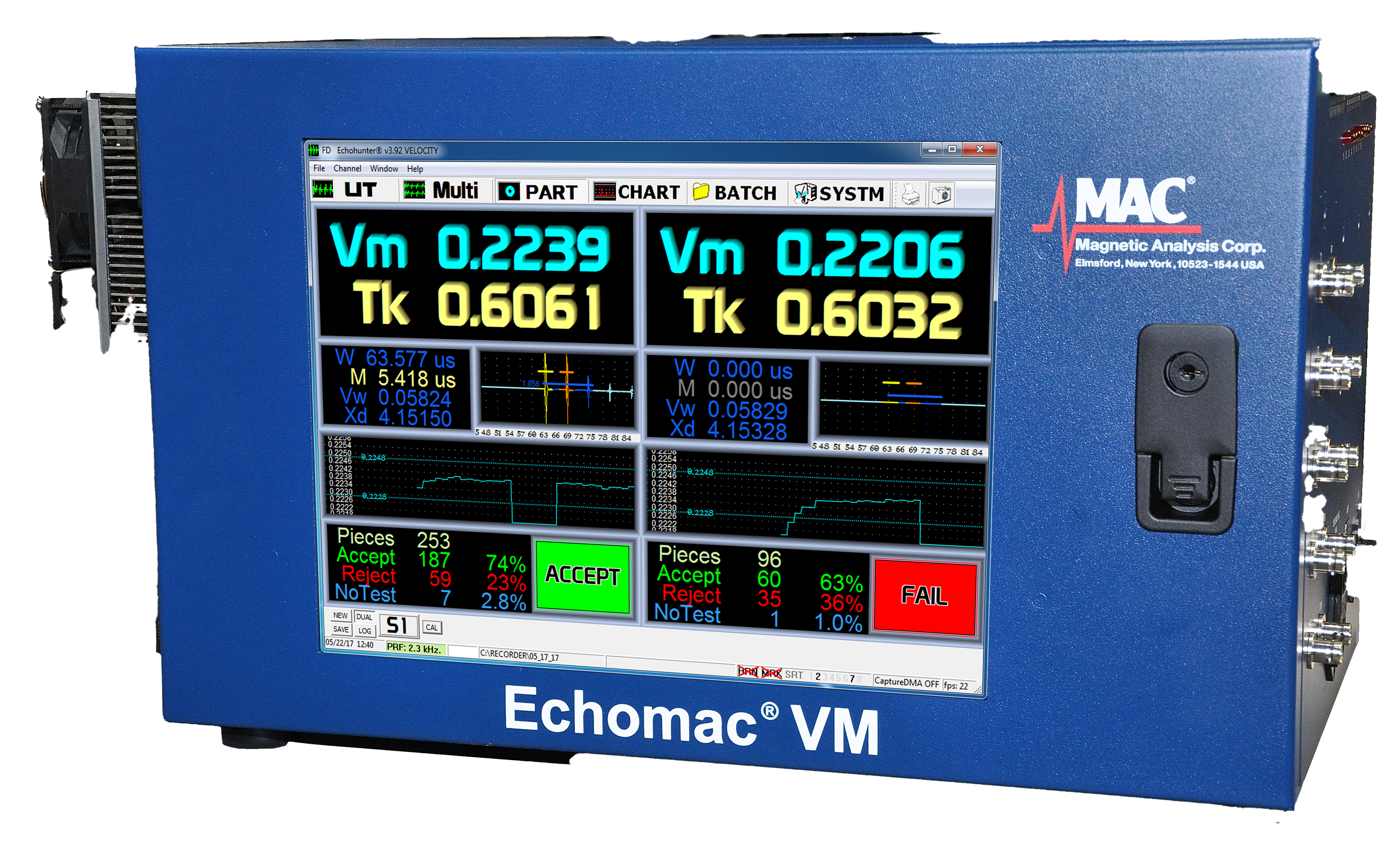

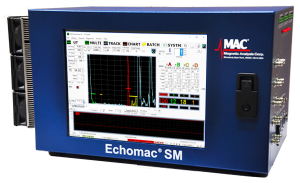

- Echomac®VM evaluates velocity, thickness or flaw detection.

- Operates with either full immersion or bubbler couplant technology.

- Enables the testing of two parts simultaneously–from separate test stations—using only one instrument.

- Standard configuration features two channels for Velocity and two for Flaw testing, with the option to add four additional Flaw channels.

- Industrial hardened I/O connections are protected from the environment.

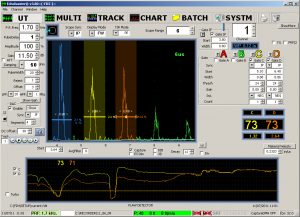

Variations in Nodularity, a type of graphite structure that can develop during the production process, can attenuate the velocity of sound waves passing through the automotive component being tested. Echomac VM measures the sound velocity and, using known limits, reports whether the part is acceptable.

Additional Features:

- Evaluations in less than 2 seconds.

- Enclosure includes a closed loop heat exchanger to

ensure proper operating temperature and protection from the

outside environment. - Dual Screen view displays test results for two parts.

- Easy to read Velocity Application screen.

- Trend Chart display and built in Data Logger.

- Adapts for automatic or manual testing.

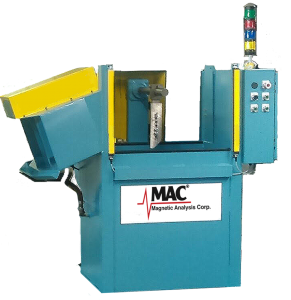

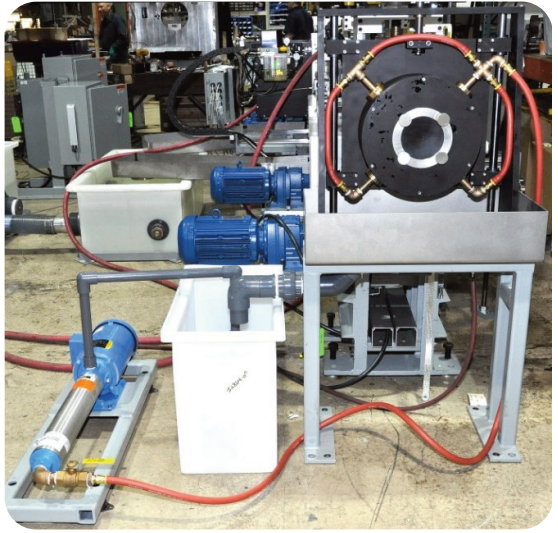

Also available is an Echomac® VM Test Tank system consisting of a heavy duty steel immersion tank, removable part fixture, automatic part ejection mechanism, air stamper for marking good parts, and full PLC control for managing the system and ensuring operator safety.

You may also like

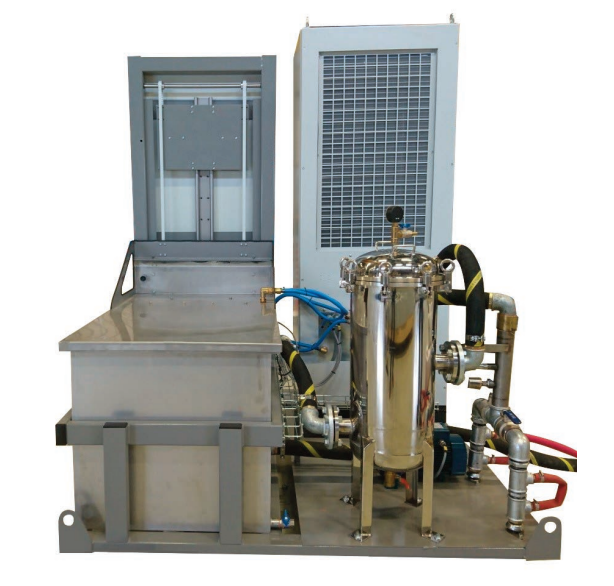

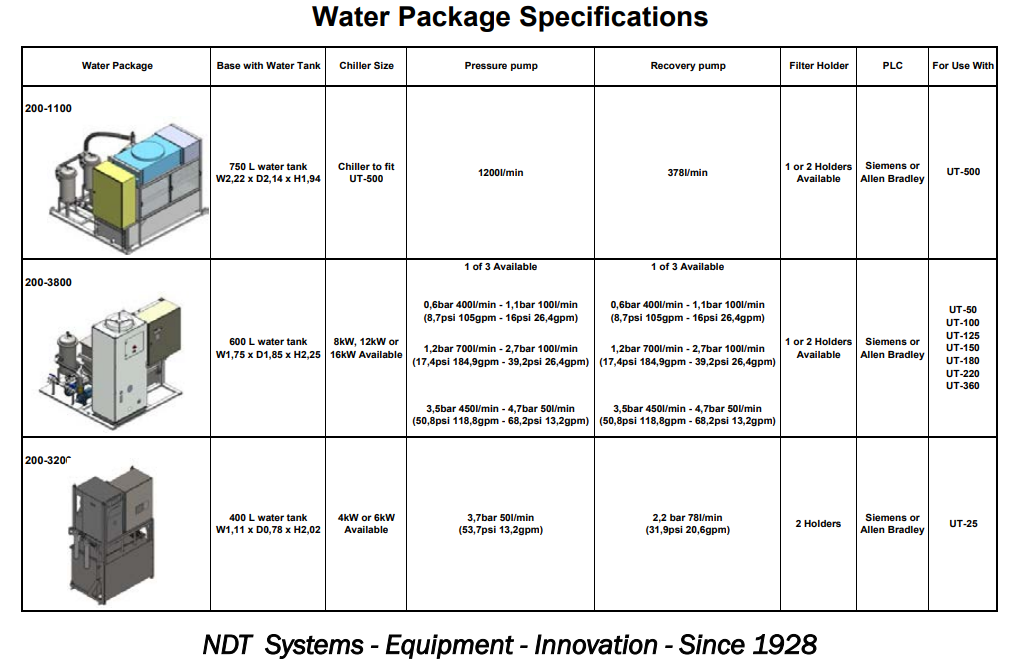

For use with Magnetic Analysis Test Systems

Prevent False Test Signals from Contaminated Bar & Tube Surfaces & Reduce Rotary Cleaning Downtime.

Simple, Effective Ultrasonic Instrument With up to 6 Channels

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar