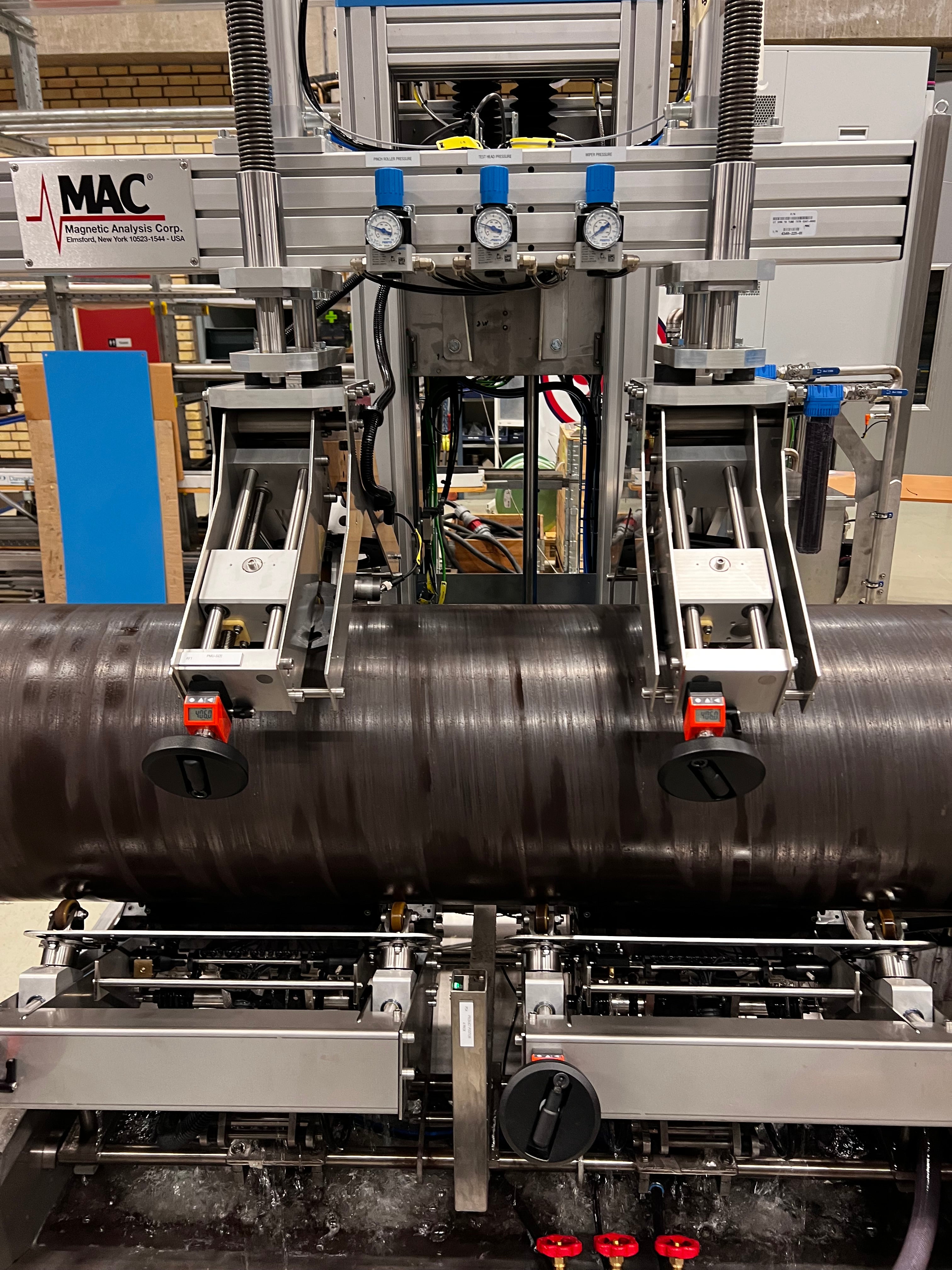

ROTOMAC® EDDY CURRENT ROTARIES

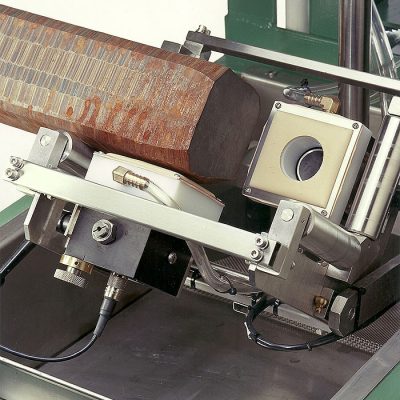

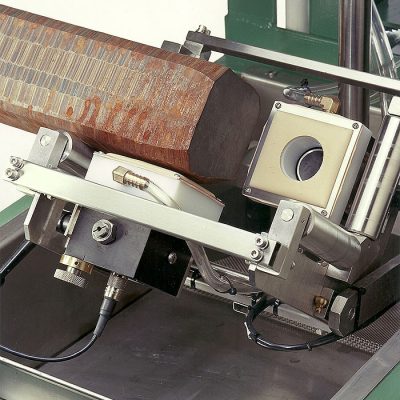

Eddy Current Rotary Mechanism to Detect Seam Type Defects in Tube and Bar

MAC Rotaries use the unique qualities of eddy current rotary probe technology to detect long continuous surface flaws which may not be detected by encircling test coils.

Operate with MultiMac® eddy current electronics.

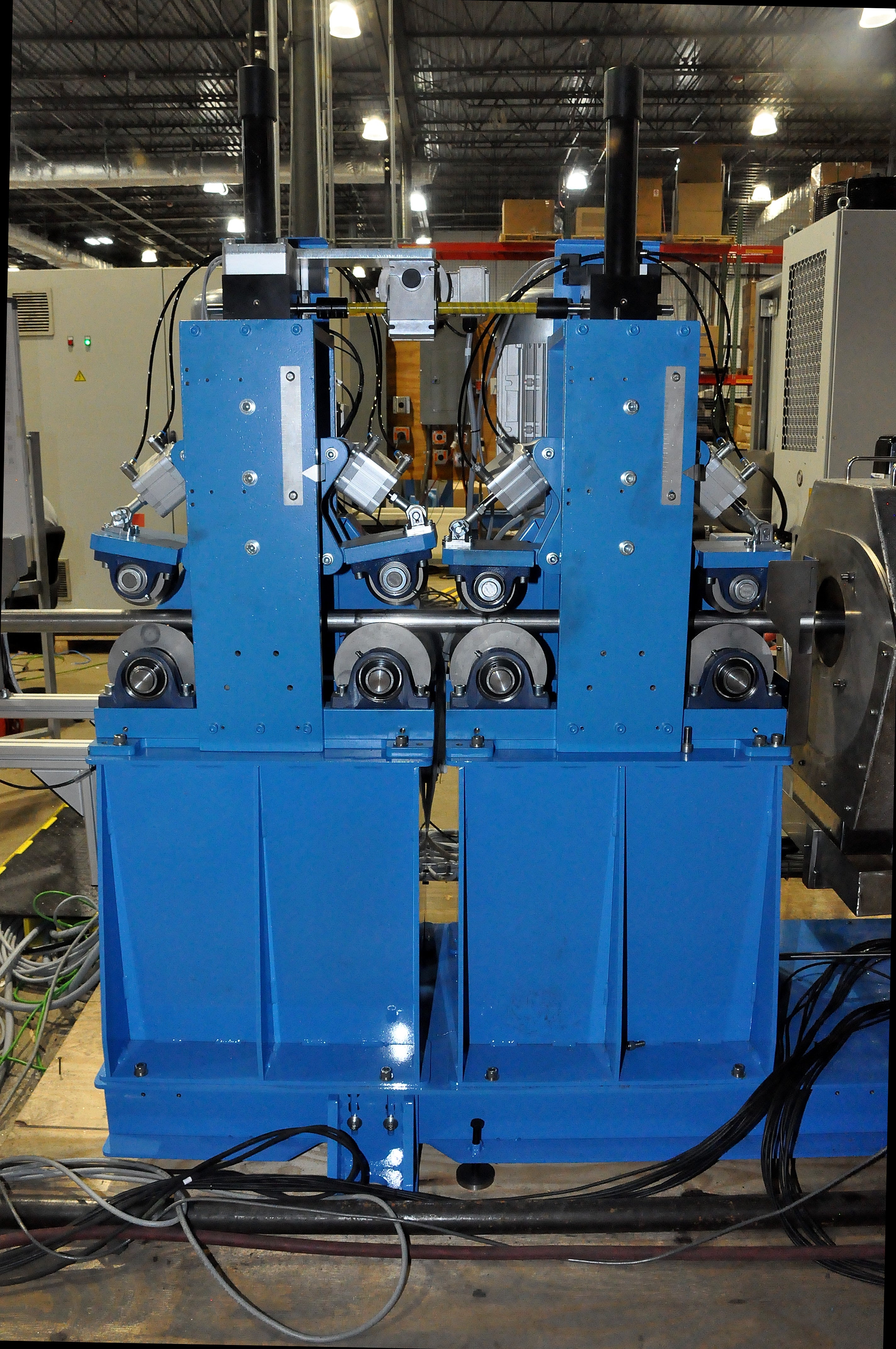

Systems with two, four, or six probes, each with its own detector channel.

Accurate Distance Compensation ensures a uniform defect signal, even with off center or out of round material.

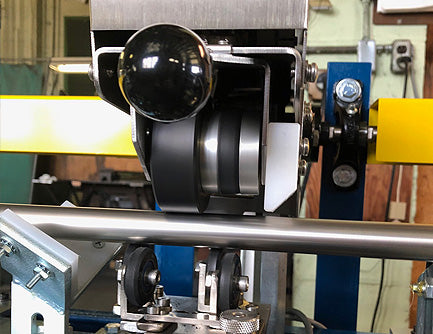

Choose test headplates for surface or air ride configurations, depending on surface conditions, sizes, and test specifications.

Dynamic breaking for quick stop of test probe headplate rotation.

Rotary probes, unlike encircling test coils, are not affected by throughput speed changes such as occur in parts forming, because the probes spin continually around the test material at a fixed speed.

Operates automatically as defects in the bar or wire create flaw signals, activate alarms, paint markers and other devices.

Test magnetic and nonmagnetic material from 1/8″ (3mm) to 7.1″ (180mm) diameter.

Method of Choice for Seam Type Defects

MultiMac® eddy current electronics provide the controls, processing and analysis for the Rotary. MultiMac® can also assign channels to an encircling coil test to detect short, intermittent defects, in combination with the rotary test, where needed.

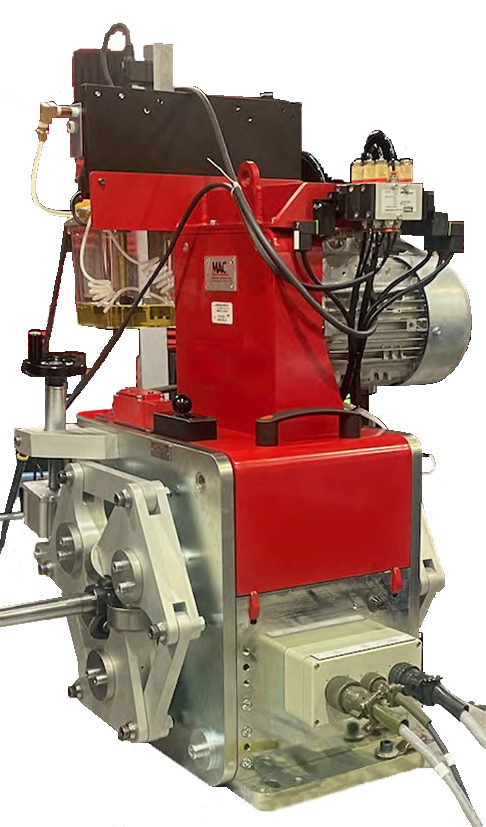

ROTOMAC® 25RM SLOW THROUGHPUT SPEED ROTARY

Cost-Effective Eddy Current Rotary for Testing Wire & Rod

The Rotomac®25 RM is the latest in MAC’s line of eddy current rotaries. Packaged with our Minimac® II eddy current electronics, it provides cost effective, reliable on-line inspection for longitudinal surface defects in wire, rod and heavy wall tube, 3 to 25mm diameter.

It is designed for use in cold header operations, spring making, strut rod production and similar slow throughput operations.

Operates at 1000 RPM.

Throughput speeds up to 12 meters per minute.

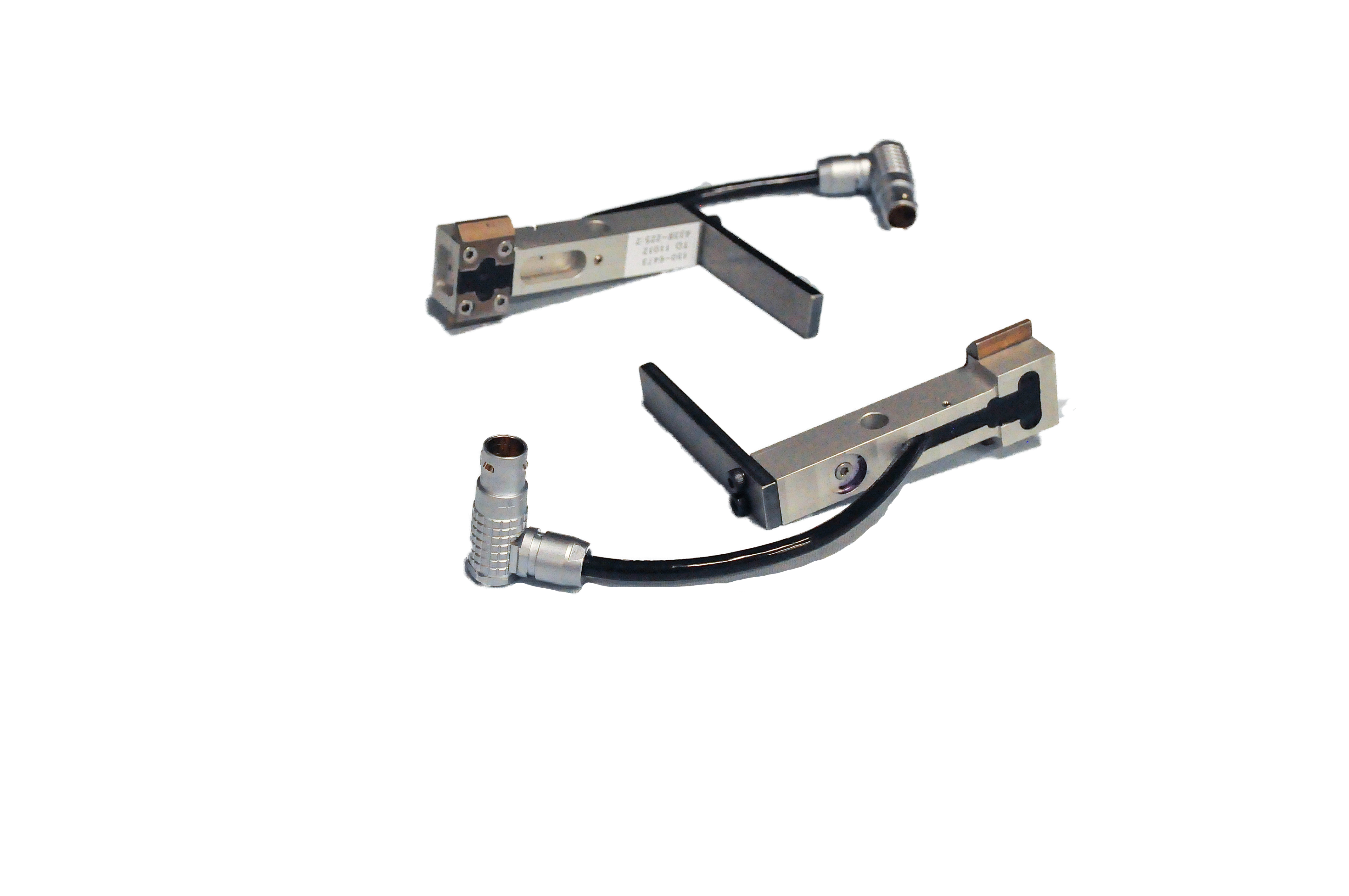

Out-of-round product can be inspected using our highly accurate distance compensation with absolute test probes.

Bushings keep product centered during test.

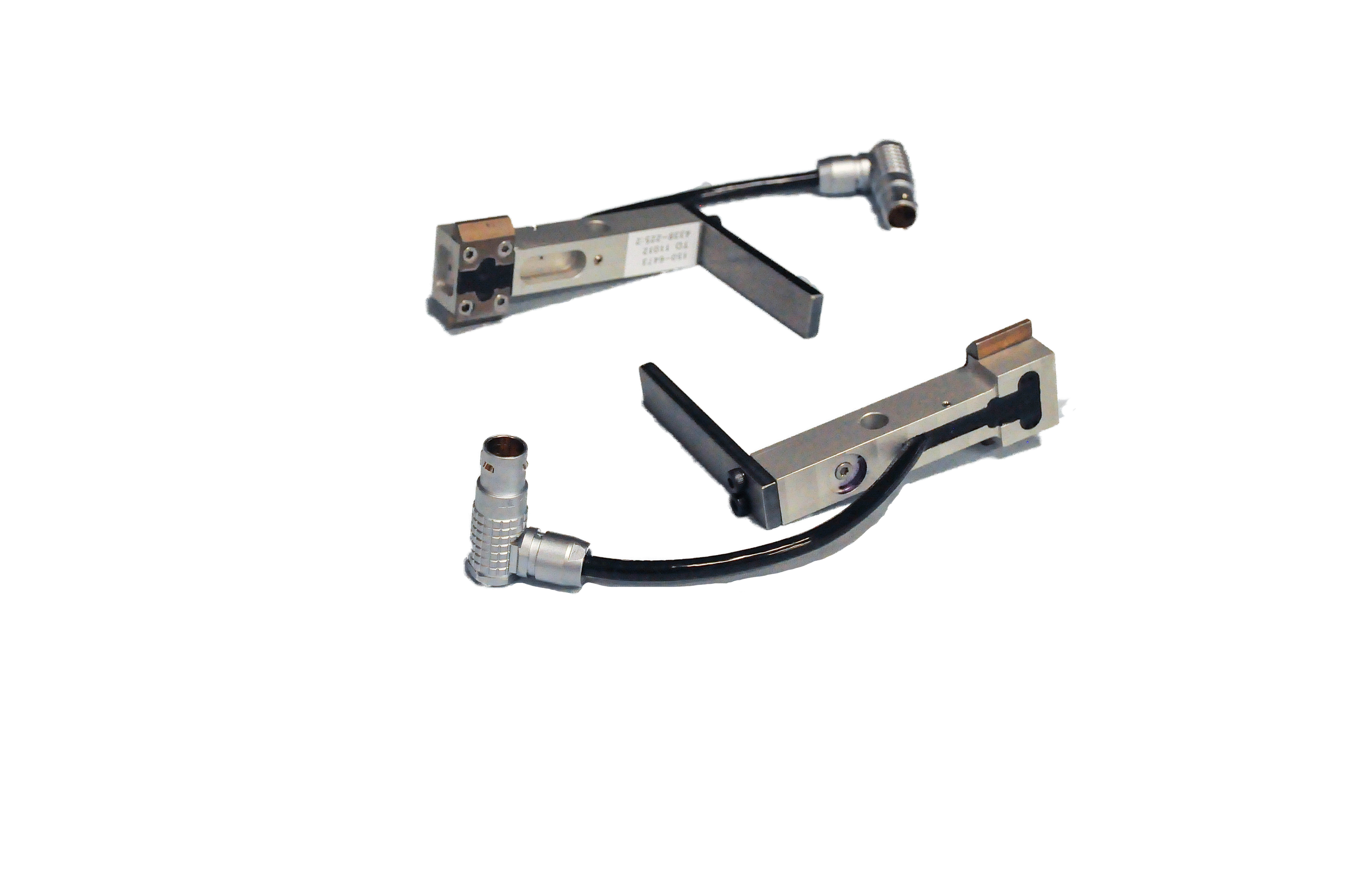

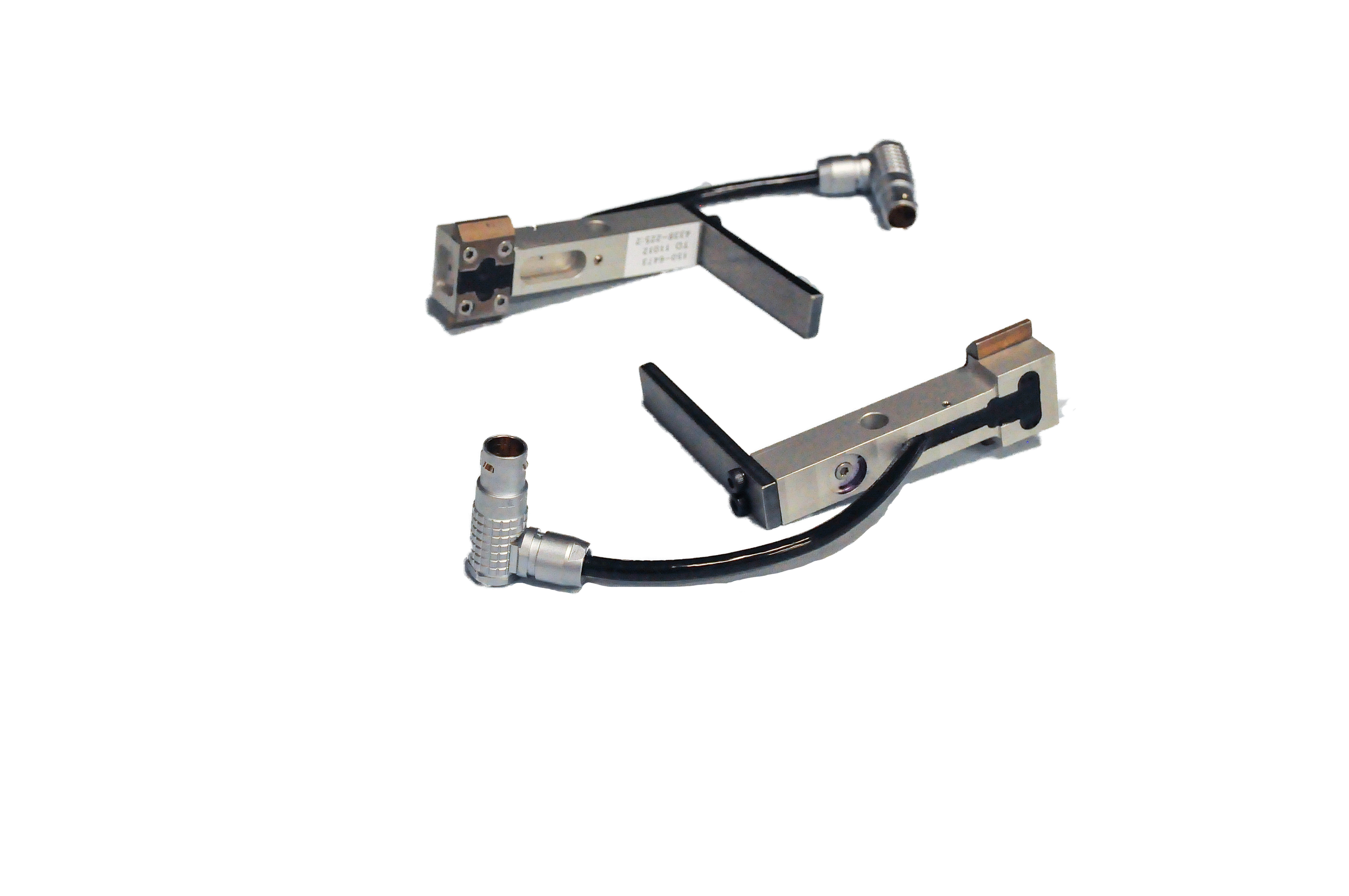

New air ride probe arm design, with convenient, easy access probe adjustment.

Standard singe phase AC power input.

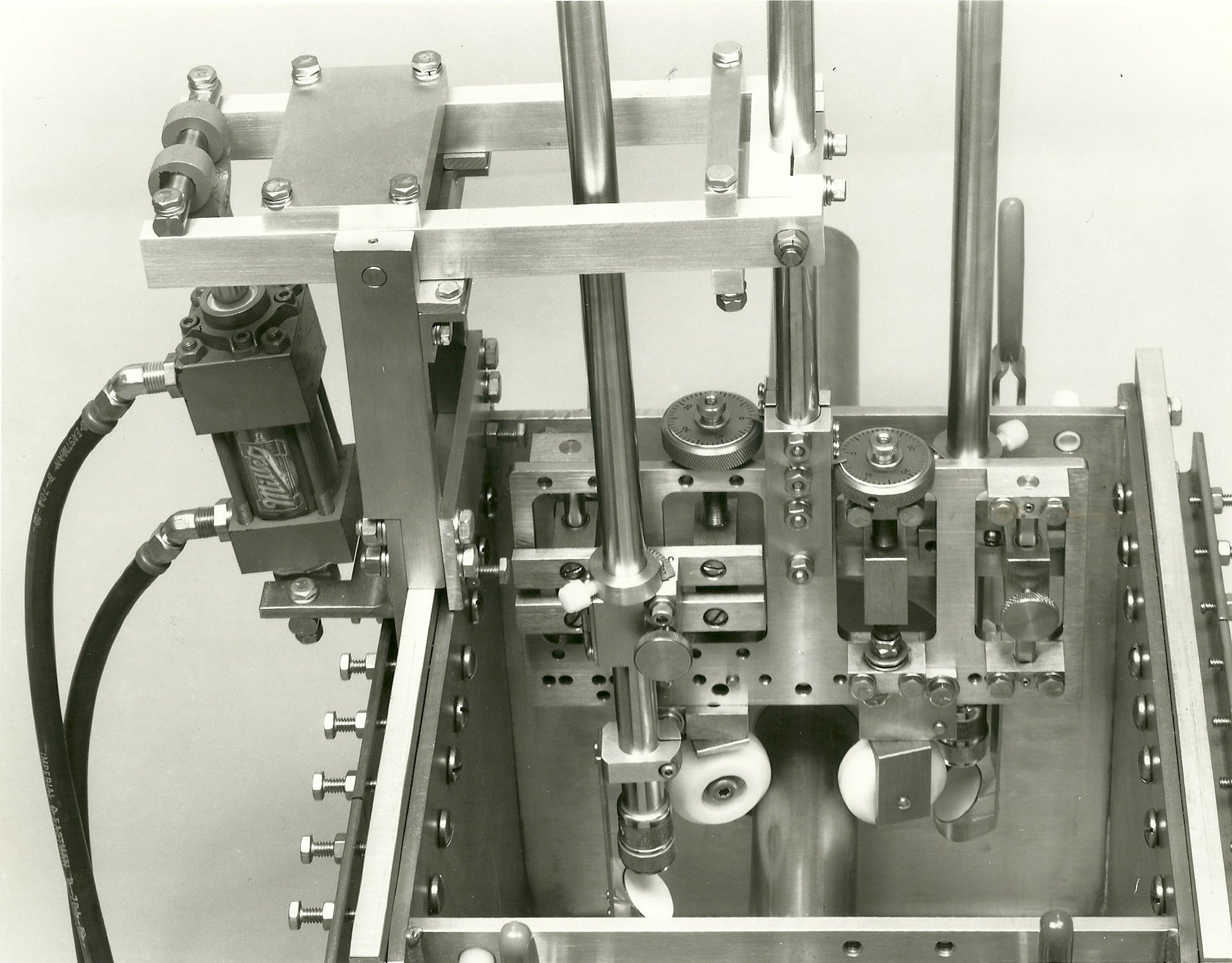

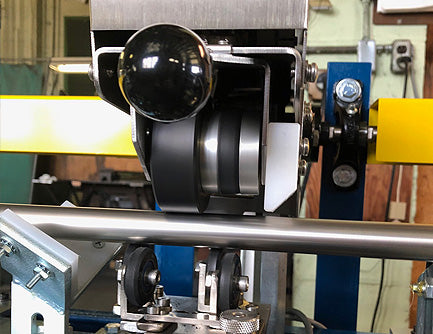

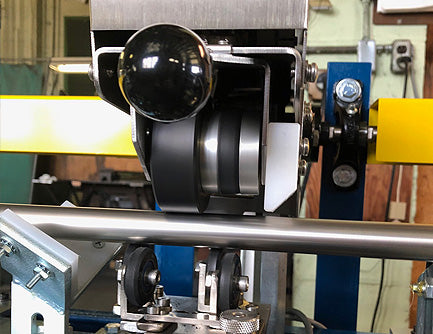

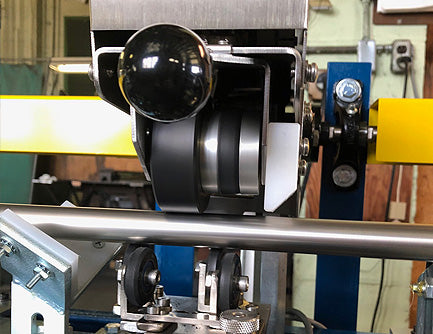

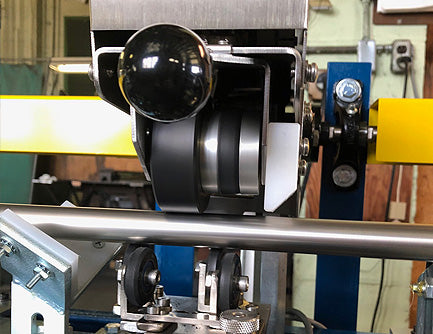

ROTOMAC® 20mm HIGH SPEED ROTARY

High-Speed Testing of Small Diameter Wire, Rod & Tube for Longitudinal Defects

High-speed rotary features include:

Operation at speeds up to 18,000 RPM for high production output.

Highly sensitive non-contact testing with superior results.

New and improved, easy to set up Distance Compensation (a critical factor in testing ovate wire).

Simple adjustment tools, with convenient dial-in diameter guide.

Two spinning test probes that can be adjusted simultaneously for dimensional changes.

Quick twist-on bushing holders.

Probes that can be easily centered on the test product’s center of rotation.

Simple probe replacement.

Meets all applicable safety requirements.

The 20mm Rotomac® HS Rotary delivers high-speed ECT (Eddy Current Testing) for continuous wire operations that include drawing, spring-making, parts forming, and shape and cut. The system is designed to detect longitudinal surface flaws such as seams and laps, in products measuring from 2 to 20mm (0.0787-0.7874”) in diameter

Applications Include:

Continuous wire operations such as drawing, spring-making, and parts forming lines.

Straight and cut operations.

Operates in-line with straighteners, or off-line in a separate test station.

Ferromagnetic, non-ferromagnetic, and austenitic materials.

Tests round and ovate material.