MAC’s New Rotoflux® AC Tester for Testing Hot Rolled Bar

Magnetic Analysis Corp. has recently introduced a new Rotoflux® AC flux leakage tester. The highly sensitive AC Flux Leakage technology is especially well suited to test hot rolled black steel bars and rods that have surface conditions which used to make finding shallow defects very difficult, if not impossible.

Ultrasonic Rotary to Test Small Diameter Bar

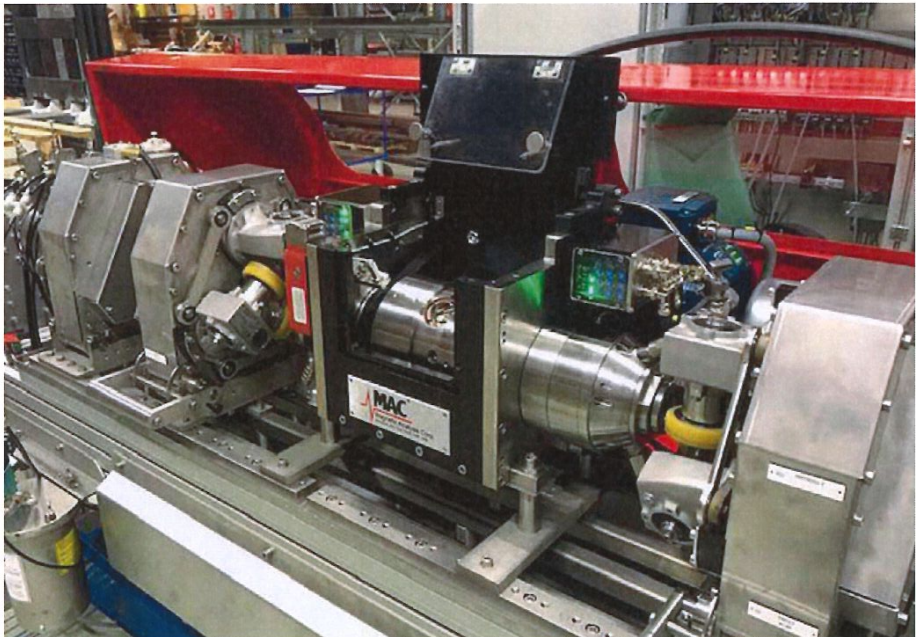

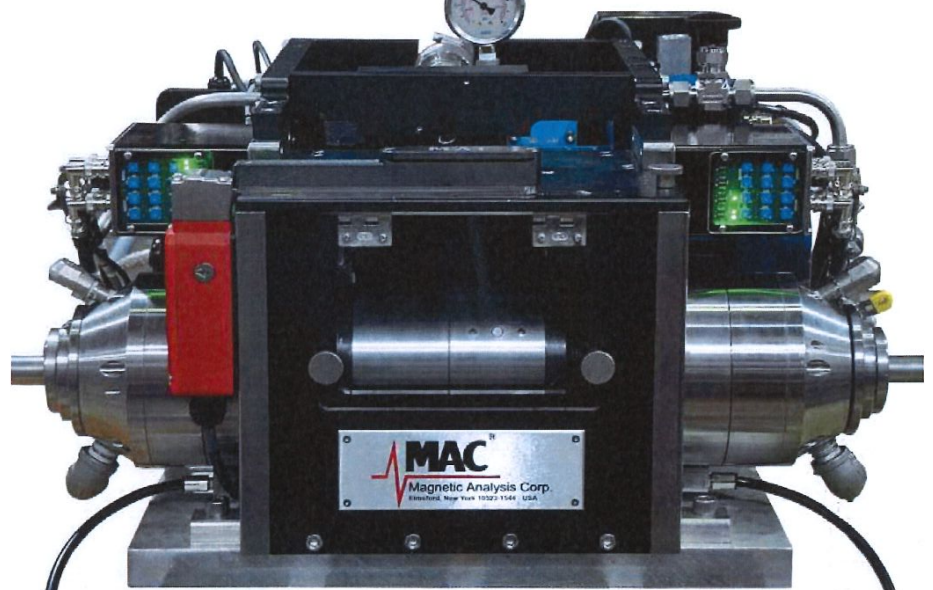

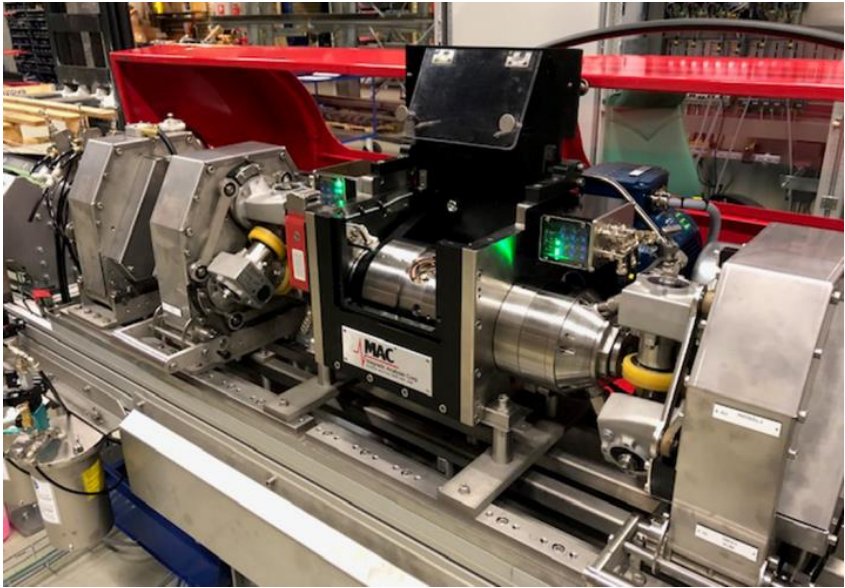

Capable of detecting the very small mandated notches dictated by the aerospace, nuclear, and medical industries. Magnetic Analysis Corporation (MAC) has recently supplied an ultrasonic test system to a major finishing processor of bars for medical components.

William S. Gould, 3rd

Magnetic Analysis Corporation is sad to report the passing of our Chairman and long-time President, William S. (“Bill”) Gould on March 14th. Bill Gould succeeded his father as President of Magnetic Analysis Corp. (MAC) in 1964 and remained in that role until 2007, a remarkable 42-year run in which he successfully built MAC from a small, U.S.-oriented eddy current testing company into a global leader in eddy current, ultrasonic, and flux leakage equipment and services.

MAC Introduces New Echomac® 25mm UT Rotary Tester

The Echomac® 25mm Rotary provides 100% coverage at high throughput rates on thin wall product ranging from 5 to 25mm diameter, and is especially well suited for challenging applications requiring high performance, such as tubular product for nuclear and aerospace installations.

Increasing Repeatability, Reliability and Productivity in Small Diameter SS

With the ever-increasing demand for small diameter stainless and specialty bars, tubes, and wires for critical applications such as automotive, medical, and aerospace, specifications are becoming more restrictive, therefore placing extreme pressure on the productivity of nondestructive testing (NDT) equipment.

MAC Delivers Eddy Current Test System for High Performance Stainless Steel Pipe

Magnetic Analysis Corp. has just delivered a single channel Multimac eddy current off-line test system designed to meet ASTM 999 (American Society for Testing Materials) specifications for testing welded stainless steel pipe.

Choosing and Applying NDT Methods for Round Stock During Production Authored by Joseph Baldauff, VP Technology

Automotive manufacturers require that all mission-critical parts must be manufactured from the highest quality material available to the raw material purchaser. Many ASTM (American Society for Testing Materials), API (American Petroleum Institute), and EN (European) specifications exist because the manufacturers of these parts must assure their customers that they meet all quality requirements.

Testing A-286 Alloy Wire for High Temperature Applications

rum Manufacturing, Inc. has been a trusted supplier of Quality Checking Fixtures and Gages for more than 35 years. Crum Manufacturing specializes in custom quality check Fixtures and Gages for many different products across a wide range of industries including automotive, aerospace and defense, industrial, appliance, plastic injection molding, etc., just to name a few.

MAC to Feature NDT Instruments & Systems at Tube 2020 Düsseldorf

Magnetic Analysis Corp. will feature NDT instruments and systems for testing tube, pipe, bar, and wire at Stand #6/H20 at Tube 2020 Düsseldorf. Highlights include MAC’s latest developments in Eddy Current, Magnetic Flux Leakage (AC and DC), and Ultrasonic technology, including the new Phased Array systems.

Testing Small Diameter, High Precision Tubes

Magnetic Analysis Corporation provides advanced inspection technologies, including eddy current and ultrasonic techniques, for accurate testing of small-diameter, high-performance tubes used in critical applications such as aerospace and nuclear industries.

Rotomac® 40mm Eddy Current Rotary to Test Rod

Magnetic Analysis Corp.’s new 40mm Rotomac® Eddy Current Rotary offers enhanced convenience for detecting seam-type surface defects in cold-drawn wire, cut-length bar stock, and parts forming. A single-handle external probe adjustment allows quick, safe dimensional changes without opening the rotary.

New Turnkey Phased Array Ultrasonic Solution for Evaluating ERW Welded Tube

Magnetic Analysis Corp’s Echomac® Phased Array system offers mechanical, OCTG, and automotive tube manufacturers a high-performance, automated solution to detect longitudinal weld zone defects and/or monitor weld profiles with minimal operator interaction.