Detecting Metallic Inclusions And Defects In Copper Tube

The Victaulic copper connection system complies with EN1057 half hard copper tubing sizes DN50 to DN150 (2 to 6") and can withstand pressures up to 2,450kPa/355psi depending on the type and size of copper tubing. The product line consists of WRAS-approved Style 606 rigid coupling with grade ‘EW’ EPDM gasket for joining copper tubing and a range of full-flow, standard radius wrought copper fittings supplied with grooves.

Planning Ahead for a Successful NDT System

As a start, suppliers should recognize that it is fast becoming mandatory for any long stock producer to pass 100 percent of the product through a test station to assure that customer expected quality levels are met.

Meeting Standards For Testing Large OCTG Tube and Pipe

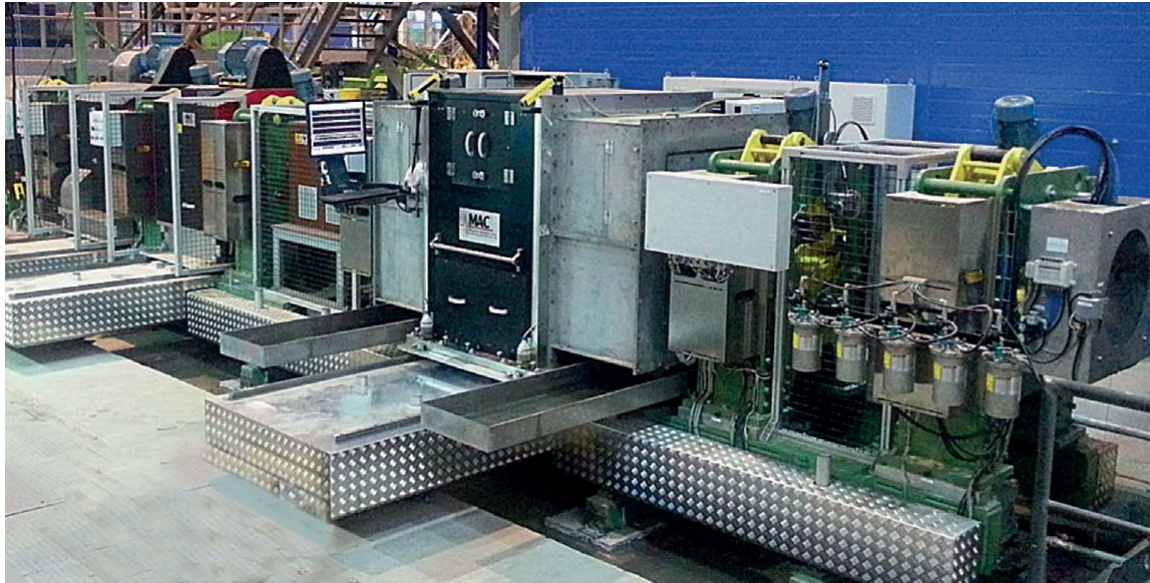

Magnetic Analysis Corp. (MAC) has recently supplied a test system to a Russian mill to inspect tube and pipe, up to 500mm (19.6”) diameter. The system features MAC’S largest ever Echomac® Ultrasonic Rotary tester combined with 500mm Rotoflux® Transverse and Longitudinal testers.

High Performance Testing

MAGNETIC Analysis Corporation (MAC) will feature the new Minimac 55 eddy current tester at this year’s Tube Southeast Asia show in Bangkok, Thailand, in September.

MAC Spotlight Article

Vielseitig, flexibel und nah am Kunden: Die US-amerikanische Magnetic Analysis Corporation (MAC) ist ein führender Anbieter zerstörungsfreier Prüfgeräte. Das Unternehmen, das 1928 gegründet wurde, hat seinen Sitz in Long Island City, New York. In den vergangenen 87 Jahren hat sich das Unternehmen zu einem weltweit tätigen Anbieter zerstörungsfreier Prüfgeräte entwickelt.

MAC So Much More than an Equipment Maker

Since being founded 87 years ago in Long Island City, New York, Magnetic Analysis Corporation (MAC) has become a leader in the nondestructive testing industry. The company was responsible for developing the first American made system using electromagnetic principles for the detection of flaws in steel products.

MAC A Global Partner in NDT SOLUTIONS

Since being founded in Long Island City, New York, in 1928, Magnetic Analysis Corporation (MAC) has grown to become a worldwide leader in the nondestructive testing industry. The company developed the very first American-made nondestructive testing system using electromagnetic principles for the detection of flaws in an assortment of steel products.

MAC Features Tube, Bar And Wire Test Systems

FIVES, an industrial engineering Group with a heritage stretching back more than 200 years, designs and supplies machines, process equipment and production lines for the world’s largest industrial groups, including the aluminum, steel, glass, automotive, aerospace, logistics, cement and energy sectors.

MAC Eddy Current Tester Received Strong Interest

The new high-speed Rotomac® eddy current tester for small diameter wire and rod from Magnetic Analysis Corp. (MAC) received strong interest from wire 2016 attendees.

MAC Introduces Improved Ultrasonic Weld Line Tester

Magnetic Analysis Corp. has recently supplied a new Echomac® WLD ultrasonic weld line test system for an Ohio tube mill. Featuring new operating conveniences for inspecting tube weld zones on-line during continuous production, the system is designed to test for longitudinally oriented defects that are typical of the ERW welding process.

MAC Appoints President/CEO

Mr. Boden is now focused on broadening the firm’s product offering in order to take advantage of new opportunities that have arisen. “Boden’s work in expanding overseas operations and strengthening the sales force and office procedures is providing a firm basis for future successful initiatives under his leadership,” commented MAC chairman William S. Gould 3rd.

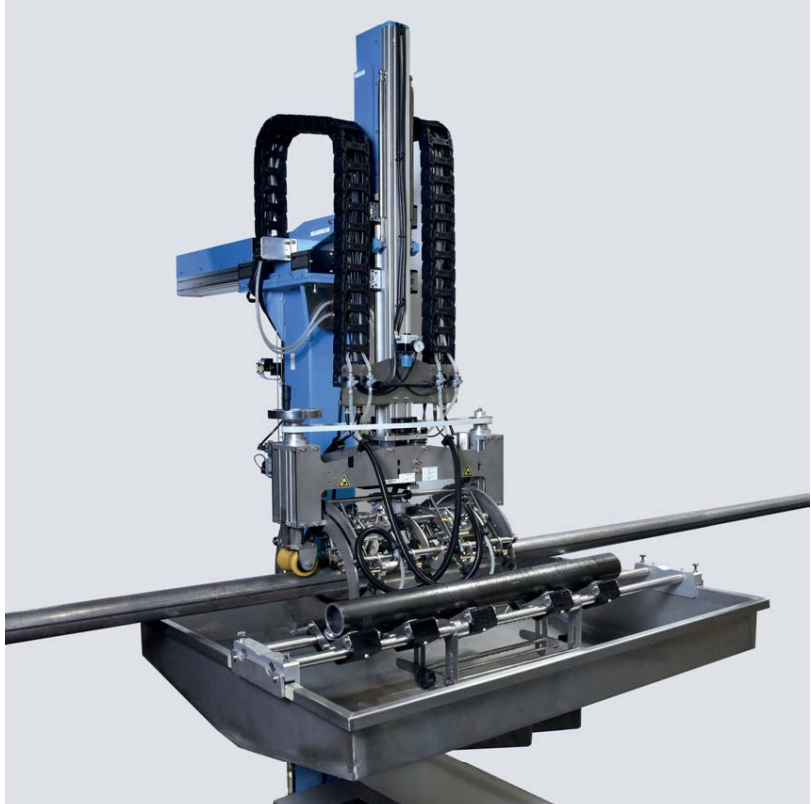

MAC System Tests For Eccentricity During Tube Drawing

MAC system tests for eccentricity during tube drawing ECCENTRICITY, where the OD and ID are not concentric, is a problem that is most often created during extrusion of the billet before being drawn into a tube.