Full Body Ultrasonic Inspection Of Spinning Tube

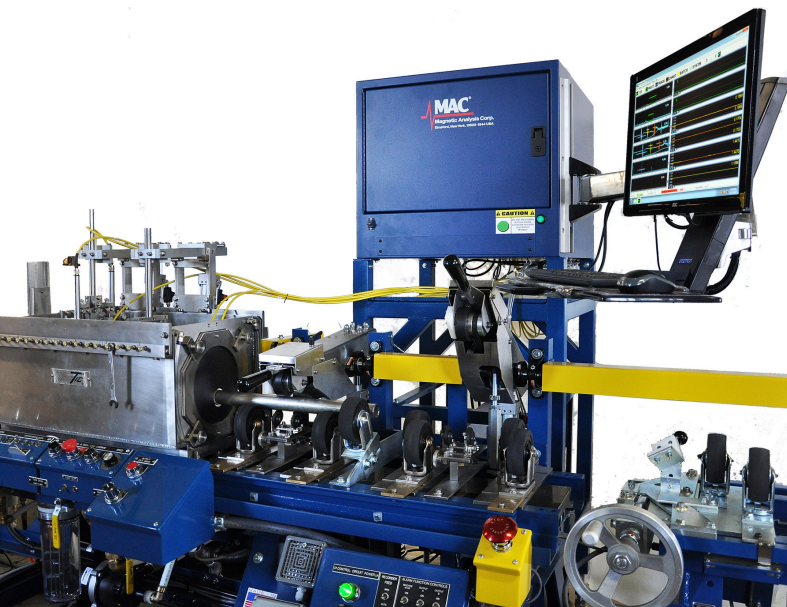

Magnetic Analysis Corp. (MAC) has developed an Ultrasonic Spin-the-Tube inspection system utilizing MAC’s Automated Pitch Control (APC) Technology, and a premium grade conveyor designed specifically for testing applications.

Top Products Of 2016: Rotary Eddy Current Tester

The high-speed Rotomac® rotary eddy current tester for small diameter wire and rod is available from Magnetic Analysis Corp., Elmsford, NY, USA. The Rotomac eddy current tester is designed for ease of use and superior performance in detecting longitudinal, seam-type defects in small diameter wire and bar from 2 to 20 mm diameter.

Testing Small Diameter Nitinol Wire

Magnetic Analysis Corp. has introduced an eddy current test for detecting cracks and inclusions in Nitinol wire. An alloy made of approximately equal parts nickel and titanium, Nitinol is referred to as a SMA (shape memory alloy). It is often used in critical surgical applications such as stents and heart valves

There’s Optimism In the Air: Magnetic Analysis Corporation

Dudley Boden, president and CEO of Magnetic Analysis Corporation, believes the steel industry is at the beginning of a recovery. Activity levels in the OCTG sector are beginning to increase and, despite the obvious challenges presented by the current economic and geopolitical climate, there’s light at the end of the tunnel.

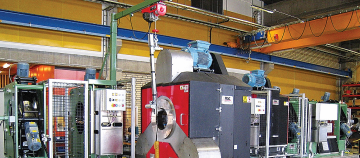

Ultrasonic/Eddy Current System for Automotive Shock Absorber Tubing

Magnetic Analysis Corp. (MAC) has supplied an ultrasonic/eddy current multi-test system to inspect cold-drawn welded tube used in the production of shock absorbers at a Monterrey, Mexico plant operated by Prosankin (formerly A-4C-Sankin).

MAC To Exhibit Latest Echomac® UT Instrument At Fabtech

MAGNETIC Analysis Corp (MAC) will be featuring its Echomac® FD-6/6A ultrasonic test equipment at booth 810018 at the FABTECH 2017 show. Information will be available on a variety of applications, ranging from full-body testing for spinning tube and weld zone inspection during production to 500mm ultrasonic/flux leakage multi-test systems for large-diameter pipe.

Critical NDT Applications

Nondestructive testing, commonly referred to as NDT, was first developed in the late 1800s. In the years since, a variety of technologies have been developed, including Eddy Current Testing (ECT) and Ultrasonic Testing (UT), which will be our focus. These two methods often complement one another when used together.

Exploring NDT options for energy-related tube, pipe products, Authored by Joseph Baldauff, VP Technology

As the oil and gas industry has changed over the years, the quality standards for tube and pipe have gained in importance. Drilling is taking place in more remote locations, often many miles offshore; horizontal drilling capability allows drilling at ever-greater distances; and to find new sources, drilling is going deeper than ever before.

Velocity Measurement for Determining Ductility and Nodularity in Cast Iron, Authored by Zhongqing You, PhD, VP Eng.

Traditional Ultrasonic Testing • Sound travels into the part, reflecting from a defect – “Flaw Detection” • Reflector size is also determined by signal amplitude – “Flaw Sizing” • Sound travels into the part and returns after a measurable length of time – “Thickness Gaging”

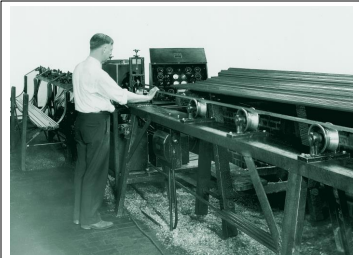

The Test of Time: Magnetic Analysis Corp. Celebrates 90 Years

ELMSFORD, NY, June 11, 2018—Magnetic Analysis Corporation (MAC), a leader in nondestructive testing, is celebrating 90 years of designing and supplying innovative inspection instruments and systems for metal manufacturers throughout the world.

NDT for Stainless Steel Tube and Bar, Authored by Joseph Baldauff, BDM

Nondestructive Testing (NDT) has been around for many years, but what we are seeing today is a swift growth in when it needs to be used. More and more makers of stainless steel products are finding they must insist on the highest quality possible raw stock for their production needs.

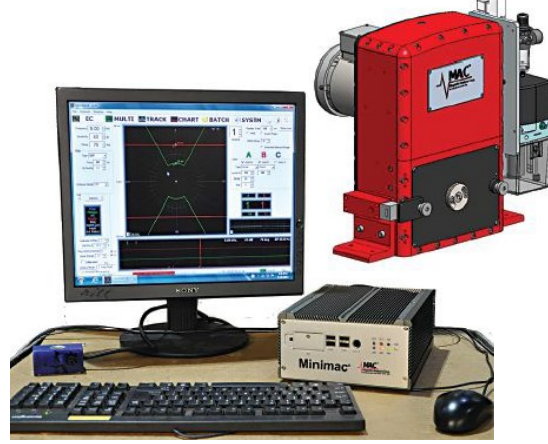

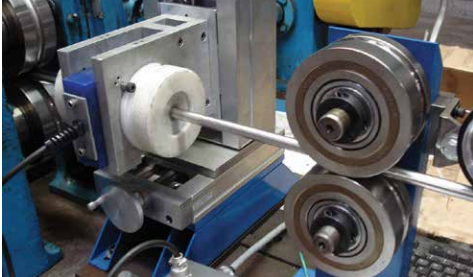

MAC’s Echomac® FD-6A and TACTIC UT Immersion System for Critical Applications

A recent test system supplied to a producer of titanium tubes for nuclear applications incorporates MAC’s (Magnetic Analysis Corp.) Echomac® FD-6A ultrasonic instrumentation with TACTIC’s (TAC Technical Instrument Corp.) ultrasonic transducer immersion tank, mechanical handling, controls, and “spin the tube” conveyors to provide a complete turnkey installation.