TESTING BAR

Depending on the requirement, situation and the type of material, Eddy Current, Magnetic Flux Leakage and Ultrasonic testing methods can be used together or alone to inspect round, hex, and square bars for defects and integrity. These inspection methods can be applied to carbon steels, stainless alloys, aluminum, titanium, and all other non-ferrous metals. Bars can be as rolled, peeled or drawn and surface improved.

STAINLESS STEEL ALLOYS

Many materials fall into the category of stainless steel alloys, including austenitic, martensitic, duplex, ferritic and other types of stainless steels. These are most easily NDT tested in both tubular form or in bar stock form (long constant cross section).

INSPECTING STAINLESS STEEL WELDED TUBE

MAC’s Minimac® II eddy current instrument is a high performance yet affordable, compact tester that is used to inspect a range of tubing, including stainless steel, copper, cold drawn welded, and seamless.

PHASED ARRAY UT UPGRADE PROGRAM FOR METAL PRODUCERS USING ROWA & BIS NDT SYSTEMS

For ROWA systems that are no longer operating at their desired level, you can rely on MAC for timely delivery of reliable, price-competitive phased array UT transducers, electronics, computers and software. This allows MAC to offer repair, maintenance, and spare parts to bring existing test systems up to the latest standards for detecting flaw/wall thickness/geometry and lamination.

ROUND & SQUARE BILLETS

MAC can offer Phased Array technology to allow simple testing of both round corner square billets and large round billets. MAC has a unique Phased Array cassette system that allows quick change between the two major geometries (round or square). The transducer assemblies follow the product surface and allow the testing to be optimized relative to the bar center.

TESTING PARTS

MAC® offers Eddy Current, Electromagnetic, Flux Leakage and Ultrasonic solutions for on- or off-line testing of hex, round and other dimensions. Typical parts being tested include fasteners, ball bearings, expanders and small tubular components. Parts may be submitted for a free evaluation and analysis conducted by MAC’s certified engineers to determine the best NDT option for your application.

OIL COUNTRY TUBULAR GOODS

Oil Country Tubular Goods (OCTG) are used in oil and gas production. As a rule, these include drill pipe, casing and tubing that are used both onshore and offshore. Producers of OCTG tube must meet the demands of individual client specifications, as well as API 5L & 5CT, ISO, EN and other standards.

NODULARITY INSPECTION

As the use of nodular graphite iron material has expanded in recent years for cast automotive safety parts, ultrasonic velocity measurement is providing a reliable, industry accepted means of verifying material integrity.

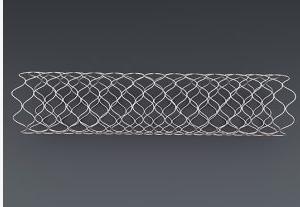

TESTING HIGH PERFORMANCE NITINOL WIRE

Magnetic Analysis Corporation has introduced an eddy current test for detecting cracks and inclusions in Nitinol wire. Surgical applications such as stents and heart valves, where the wire's ability to be deformed at one temperature during insertion, and then recover its original, undeformed shape when heated above its "transformation temperature" after exposure to typical body temperatures of 98.6°F (37°C), is essential.

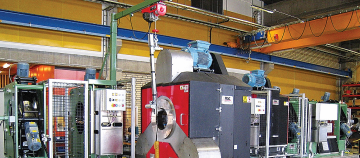

MULTI-TEST SYSTEM FOR AUTOMOTIVE SHOCK ABSORBER TUBING & OCTG

Magnetic Analysis Corp. has supplied a combined ultrasonic/eddy current test system to inspect cold drawn welded tube to be used in manufacturing shock absorbers at a new plant in Monterrey, Mexico, built by Prosankin, formerly known as A-4C-Sankin. The plant’s focus is production and sales of cold drawn tubes primarily for automotive use, although the test system is also designed to provide the future capability of meeting API 5CT testing requirement for oil country tubular goods (OCTG).

MEDICAL TUBE AND WIRE

As NDT techniques have expanded, so have the applications which now encompass many critical products that are being used where it is extremely difficult and expensive to replace or repair, or where failure can cause serious and life threatening consequences.

HEAT EXCHANGER TUBE

These types of tubes are commonly found in heat exchangers used in oil refineries and for other large chemical processes, power generation and many other high liability, high down time cost applications. Many of these situations are also high pressure applications.