STAINLESS STEEL WORLD AMERICAS CONFERENCE OCTOBER 2012

AUTHORS:

Keith Doughten, District Manager, Magnetic Analysis Corporation, ASNT NDT Level III ET, UT

David Bauer, Marketing and Training Manager, Magnetic Analysis Corporation, ASNT NDT Level III ET

Michael Rakos, Field Engineer, Magnetic Analysis Corporation, ASNT NDT Level III ET

Paloma Domenico, Advertising Manager, Magnetic Analysis Corporation

CONTACT INFORMATION:

Keith Doughten: kdoughten@mac-ndt.com

David Bauer: dbauer@mac-ndt.com

Mike Rakos: mrakos@mac-ndt.com

Paloma Domenico: pdomenico@mac-ndt.com

Magnetic Analysis Corporation

103 Fairview Park Drive

Elmsford, NY 10523

Tel: 914-530-2000

ABSTRACT

This paper will discuss the selection of inspection methods for testing Super Duplex stainless product for the offshore energy exploration, petrochemical, food & beverage, and power generation industry. We will show how Eddy Current and Ultrasonics will meet requirements set up by ASTM, and EN standards in regards to Super Duplex stainless steel.

The Non-Destructive Testing (NDT) methods used for inspection of Super Duplex stainless steel products are Radiography, Eddy Current, and Ultrasonics.

Eddy Current – used to find surface discontinuities such as pits, weld defects, inclusions, and Sigma Phase variations.

Ultrasonics – used to find laminations, wall thickness variations, and discontinuities on the OD and ID such as pits, cracks, and weld defects.

Radiography – used to inspect orbital welds, strip splices, and offline verification of other NDT methods.

Super Duplex stainless steels have been around for 80+ years¹. Newer Super Duplex alloys are characterized by higher strength and better stress corrosion cracking resistance than most austenitic alloys. This has increased the need for more stringent eddy current testing. This increase is particularly found in the onshore and offshore oil and gas industry, chemical processing, heat exchangers for power generation, desalination equipment, and wastewater treatment facilities.

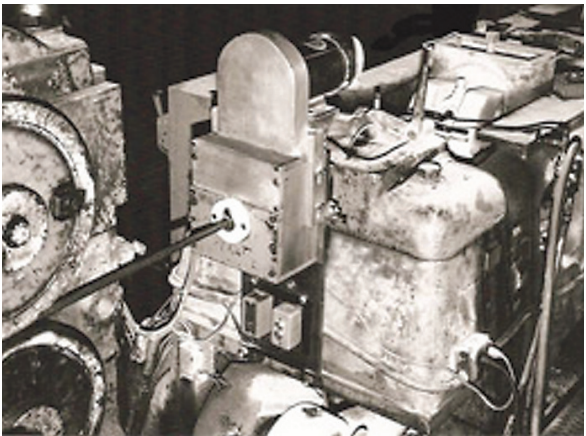

Eddy Current testing is one of the most widely used NDT Inspection methods for metal tubular products. It is relatively easy to use, works within a wide range of production speeds, and has a relatively low cost of operation. However, Duplex and Super-duplex Stainless Steel tubes by definition contain about 50% ferrite in their microstructure, which results in permeability variations within the grain boundaries of the microstructure of the Duplex Stainless product. These permeability variations present a problem for eddy current testing in that they act to shield or prevent the penetration of the eddy current field from sufficiently entering the metal and thereby yield poor test results².

The use of an Eddy Current encircling coil coupled with a saturation coil suppresses the effects of permeability variations which appear as “noise” within the test results. Another use of Eddy Current is to identify Sigma Phase variations. Sigma phase is an iron-chromium (roughly 50-50) phase that can form from ferrite in austenitic stainless steel weld metal at elevated temperatures (approximately between 450°C and 850°C; some believe it goes to 1050°C)³. It therefore forms during high-temperature service, and its presence in the stainless steel is only apparent at room temperature. During plant shutdown, the stigmatized material becomes extremely brittle and will crack readily with low toughness⁴.

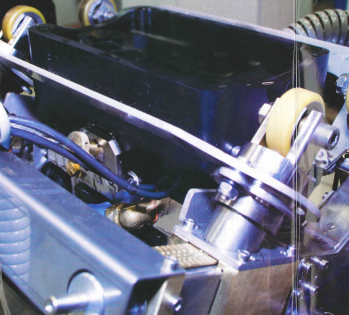

Multiple Channel Rotary Ultrasonic Immersion testing is used for detection of discontinuities as well as wall thickness variations. The use of high-speed rotaries enables the testing to keep up with production output.