Minimac® II lets you take advantage of eddy current technology’s versatile capabilities to deliver high-performance testing for tube, bar, wire and parts. With an embedded host computer, this fully digital instrument provides up to two test channels of Flaw, Absolute or any combination, at an economical cost.

- Detect short surface and some subsurface defects, including laps, slivers and cracks in tube, bar, wire and parts.

- Inspect for long, continuous defects.

- Find weld line faults including short ID or OD defects.

- Test magnetic and non-magnetic grades.

- Use up to two test channels of flaw, absolute or any combination.

- Operate at speeds up to 4000 f.p.m. with standard test coils. Operate at higher speeds with wide-spaced coils.

- Operate with one or two test channels for encircling coil applications.

- Use two channels for rotary spinning probe systems.

- Supplied as a one channel instrument with an optional second channel.

You may also like

COIL PLATFORMS

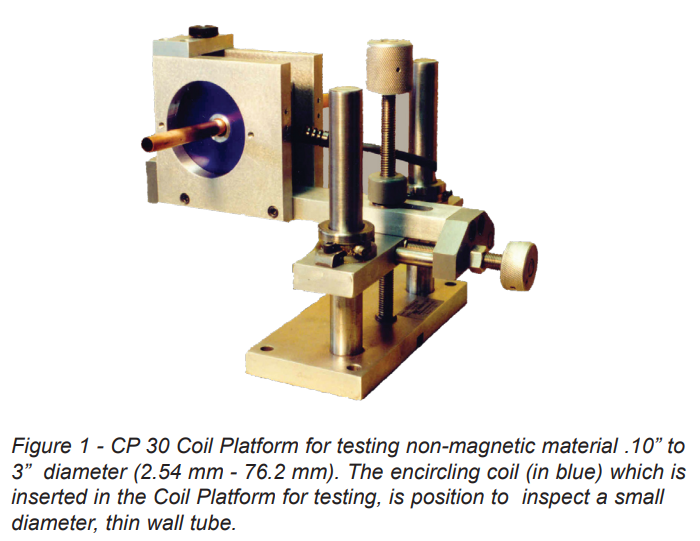

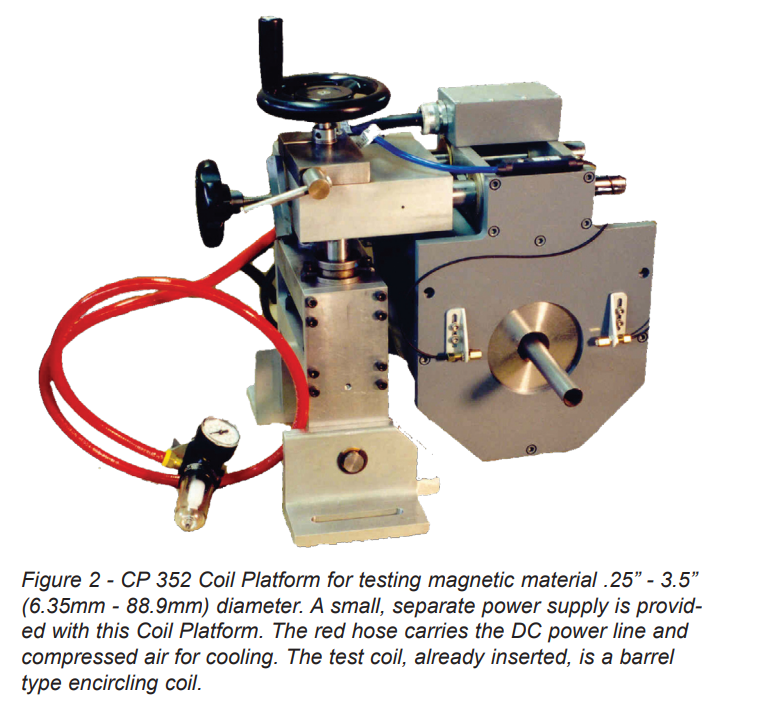

Proper positioning of the test coil with respect to the material being tested is a key ingredient of any eddy current inspection system. T