Magnetic Analysis Corp.’s line of Echomac® systems for testing ERW tube during production now includes Phased Array ultrasonic models as well as conventional ultrasonic systems.

ECHOMAC® PHASED ARRAY UT WITH ROBOT

MAC is supplying Robotic Phased Array Echomac® Ultrasonic systems to two ERW plants in the US. These cost effective, minimal operator interaction systems use a 5-axis preprogrammed robot to position the Transducer Test Head in the weld line test position, a calibration position, or quickly retract to safety when signals indicate open welds, or conditions that could cause damage. The robot’s small footprint allows flexibility in locating the test system in the line.

A single phased array transducer sequentially monitors scarf, evaluates laminar defects, and/or detects longitudinal OD/ID defects, typical of the welding process. Installation can be on-line in the hot zone, after the welder, for profile and flaw detection, or in a lower temperature area for flaw detection after forming and shaping. Live feedback on the quality of the weld and seam-trim tool is provided and no averaging or AGC is used for processing the data. B-scan and C-scan views are displayed.

ECHOMAC PHASED ARRAY UT WITH GANTRY

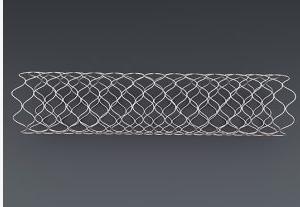

A recent Echomac® Phased Array Ultrasonic system, is testing ERW tube for Oil and Gas line pipe, ranging from 50mm to 190mm diameter with 12 different wall thicknesses. The Transducer Test Head is supported and positioned by a gantry. The test, using multi element transducers, is installed upstream in the welding hot zone where it inspects for flaws and weld profile variances that can alert the operator to weld-line processing problems, before the tube enters the forming rolls. Using Phased Array technology, the entire weld area is tested, without any mechanical movement.

CONVENTIONAL UT WELD TEST WITH GANTRY

A Weld Zone Test system using conventional ultrasonic technology is inspecting 63.5mm – 190mm diameter tubes for hydraulic cylinders destined for critical applications. The Echomac® system is installed right after the welding operation to detect OD and ID longitudinal defects, typically found in ERW processing. Individual transducer shoes can be easily exchanged for size changes in 5 seconds using the quick disconnect mechanisms. A monitor displays a laser beam that must bisect the weld center allowing the operator to quickly verify and adjust the test head with its transducer assemblies to follow the weld to achieve continuous optimal testing over a weld position of 10:00 to 2:00 o’clock.