ECHOMAC® ULTRASONIC ROTARIES

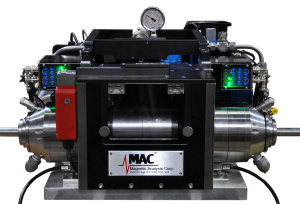

Ultrasonic Rotary Mechanisms for High Speed Testing of Round Bar and Tubular Products

MAC Rotary units are manufactured in several sizes, to inspect products ranging from 5mm to 500mm.

Applications

Oil country tubular goods – test to API 5CT and 5L standards

Seamless and welded tube

Heat exchanger tube

Hydraulic boiler tube

Umbilical tube for off shore installations

Large round billets during early stages of production

Hot rolled bar

Small diameter highly finished bar and wire

Specialty steel bars

MAC’s Echomac FD series of instruments, when used in conjunction with our rotaries, provide optimum performance and make up a complete system to test your product.

Applications

100% Coverage at high throughput rates.

Multiplex transducer design allows lower noise signals and up to 48 transducer elements.

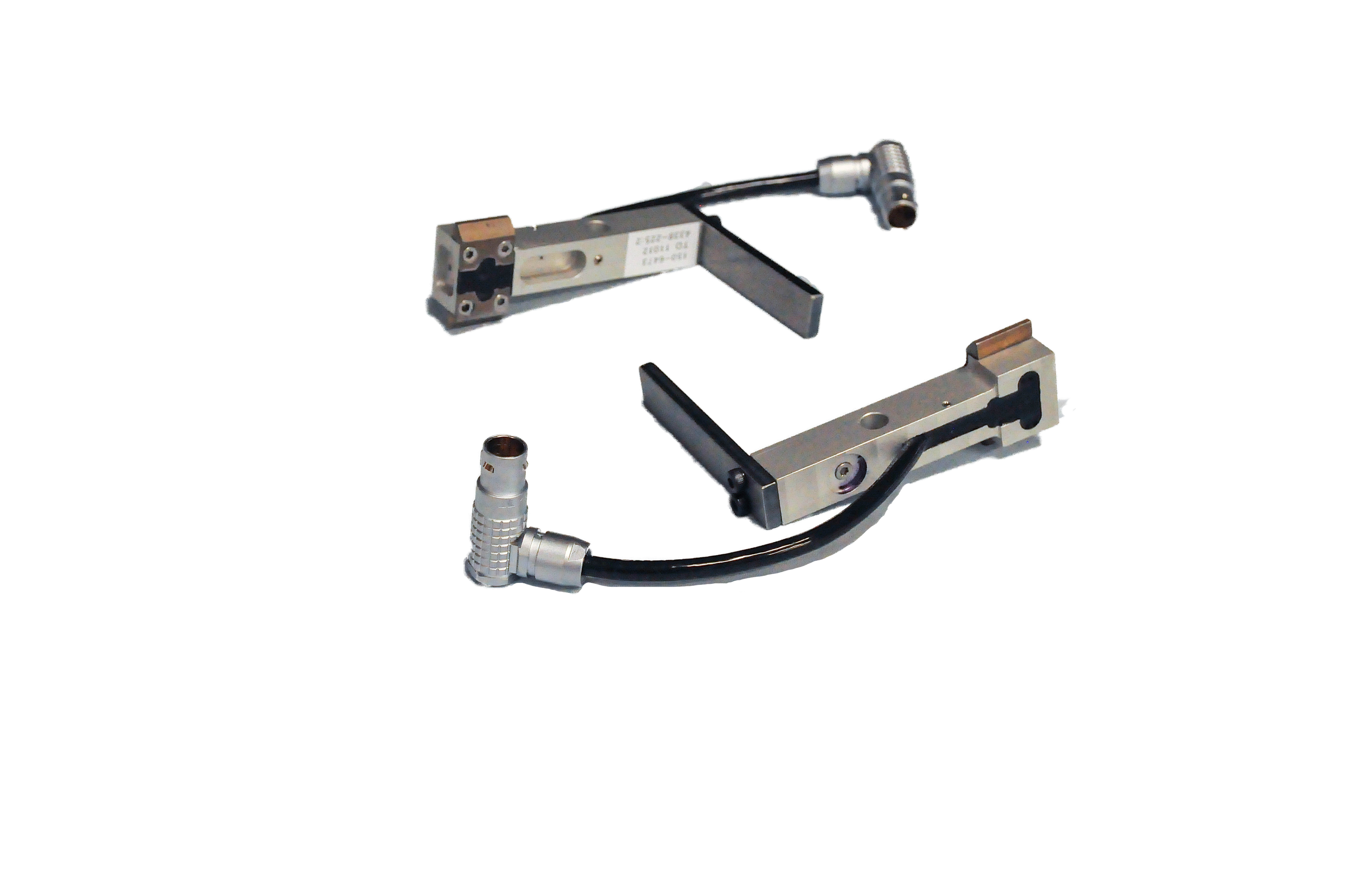

Local remote pulsar/receiver allows high gain and provides low susceptibility to mill electrical interference.

Multiple transducer elements can simultaneously test in different directions such as CW, CCW, FWD, REV, as well as measure wall thickness and detect laminations.

Precision test blocks and transducer holders ensure accurate positioning to detect small defects, even at high throughput speeds.

Seal-less rotaries reduce likelihood of damage from grit and other mill contaminants

MAC’s 25mm Rotary also features convenient adjustment of the transducer angles and an 8,000 RPM maximum running speed. The overall length of the unit is 630mm, which allows for ease of installation in existing inspection lines. Wall thickness as thin as 0.3mm, and tubes as short as 1 meter, can be successfully tested. A unique water flow control loop ensures the correct volume of water flow for coupling.

MAC designed water packages are also available, to ensure the required clean, temperature controlled water is utilized for your ultrasonic testing needs.

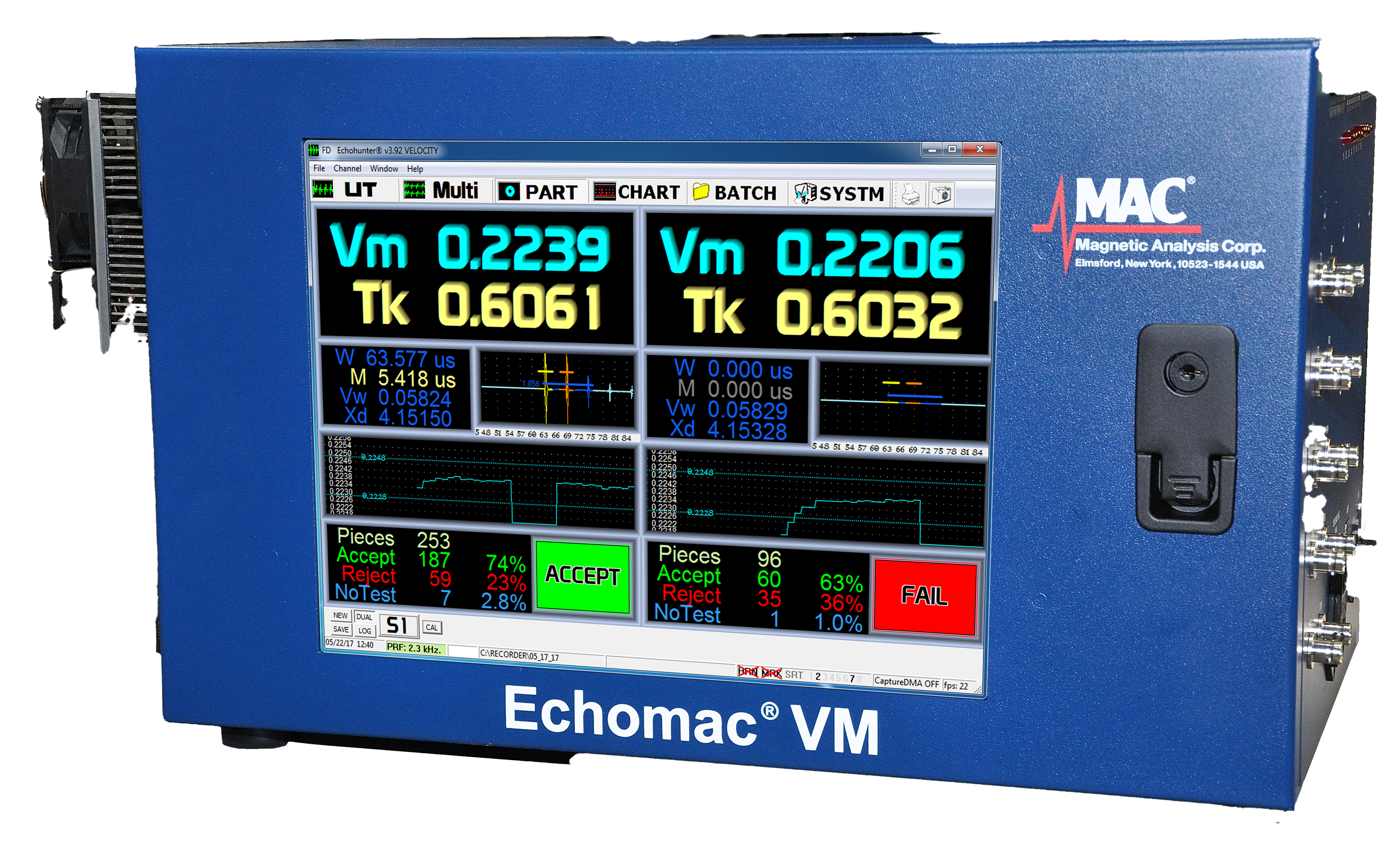

ECHOMAC® VELOCITY MEASUREMENT

Velocity Measurement to Assess Nodularity in Ductile Iron Cast Automotive Components

HEAD-PLT, 1800-3000 RPM , 8R PRB 4C

SKU: Y10P-354

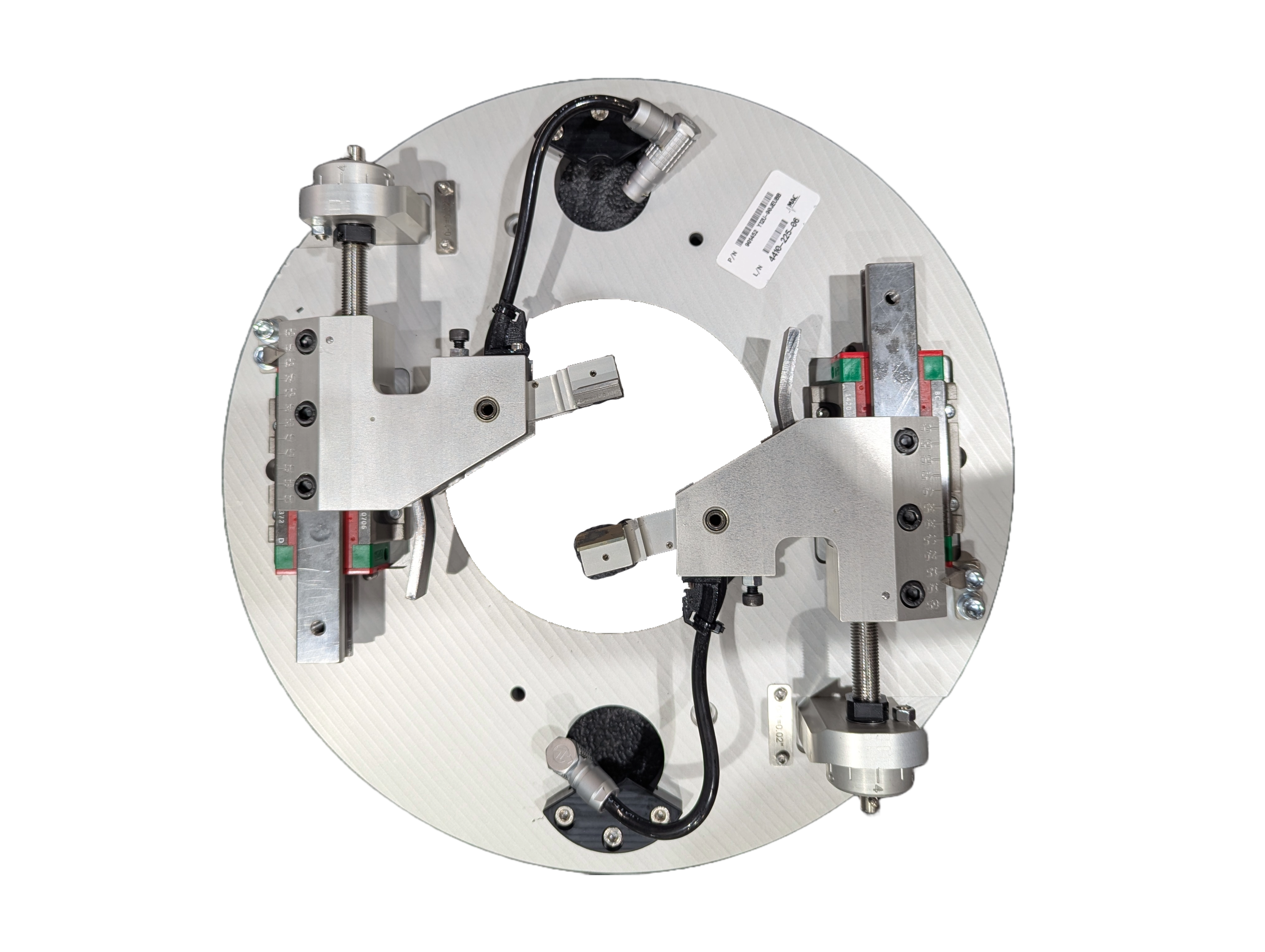

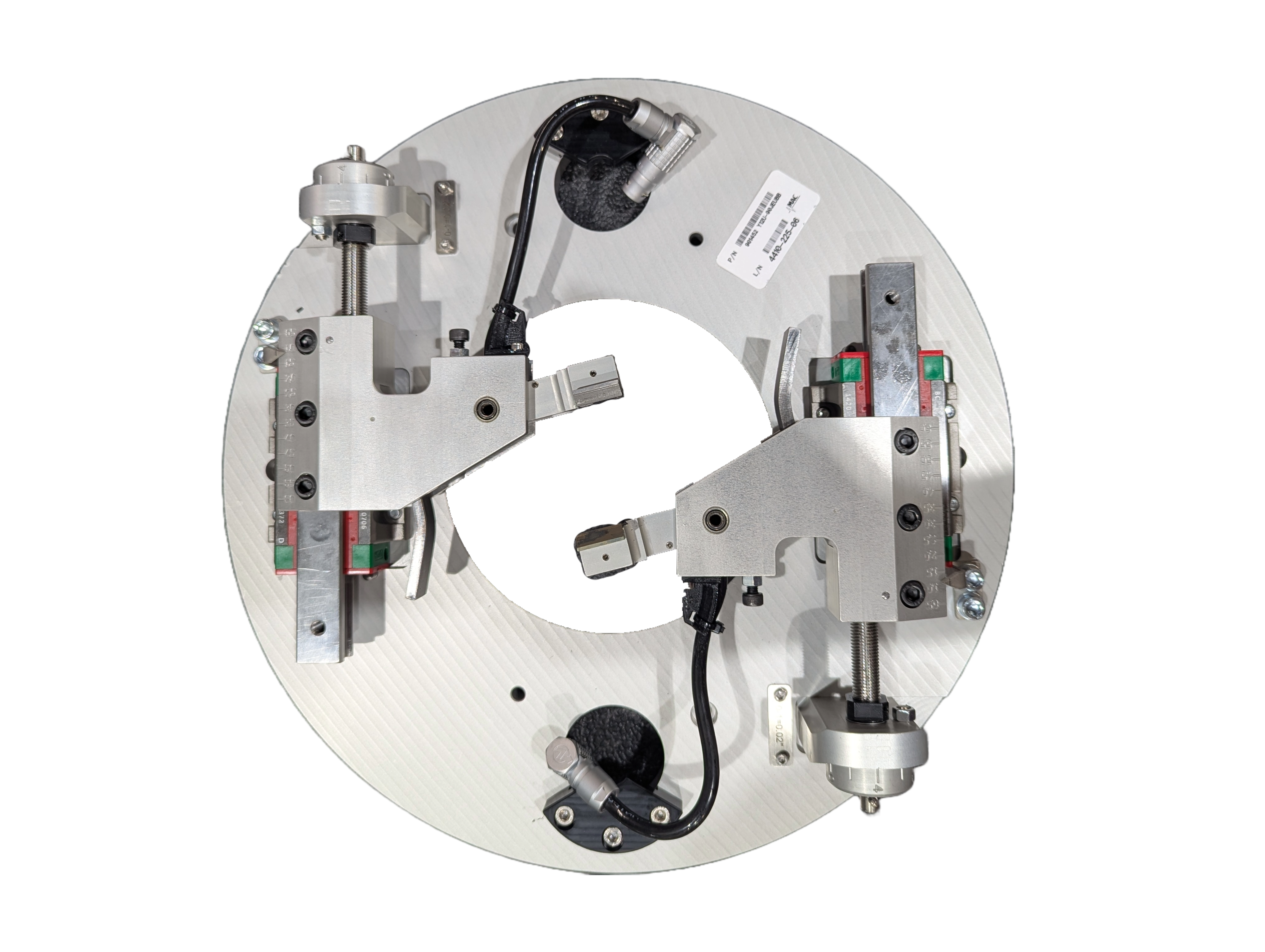

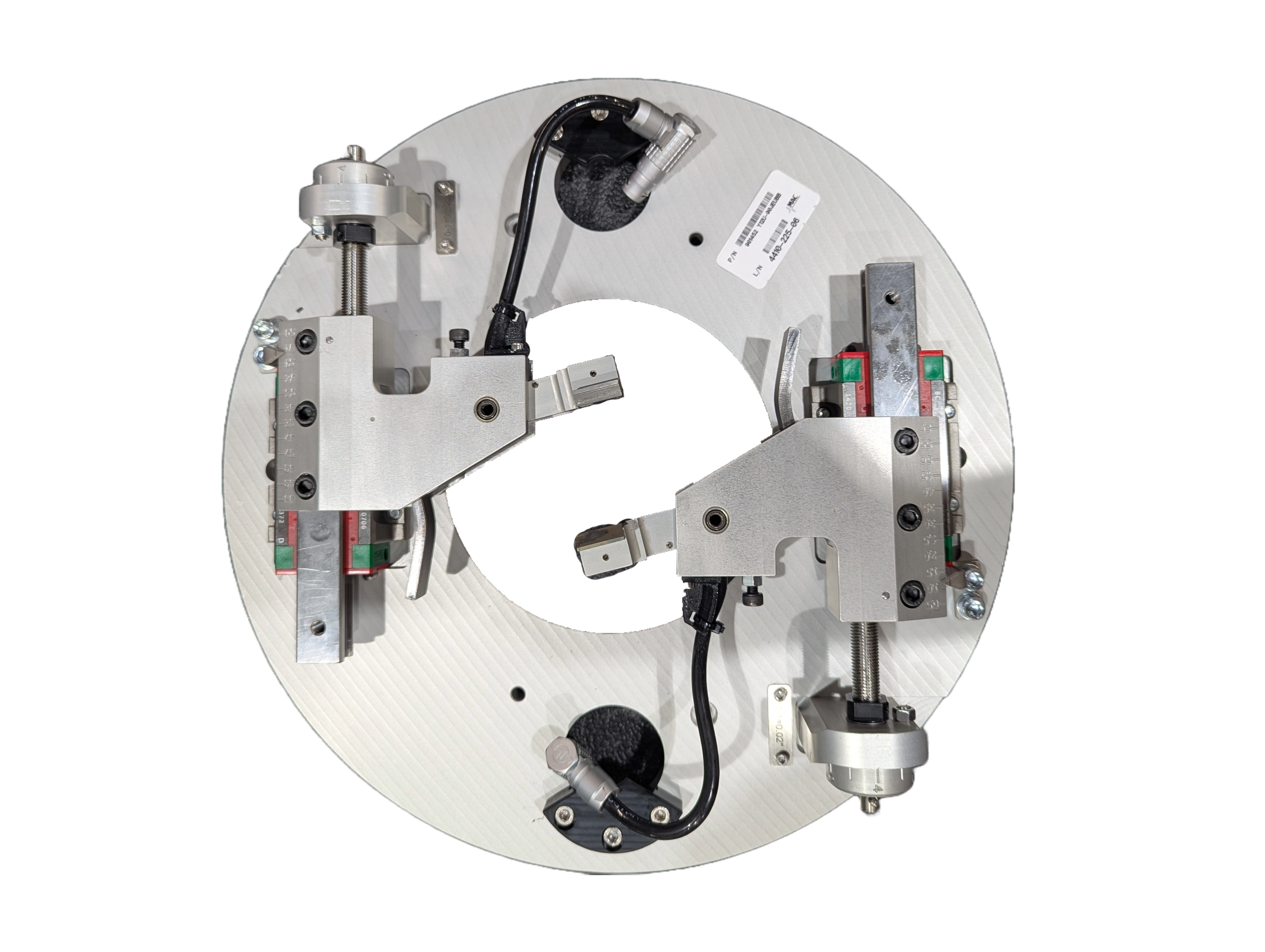

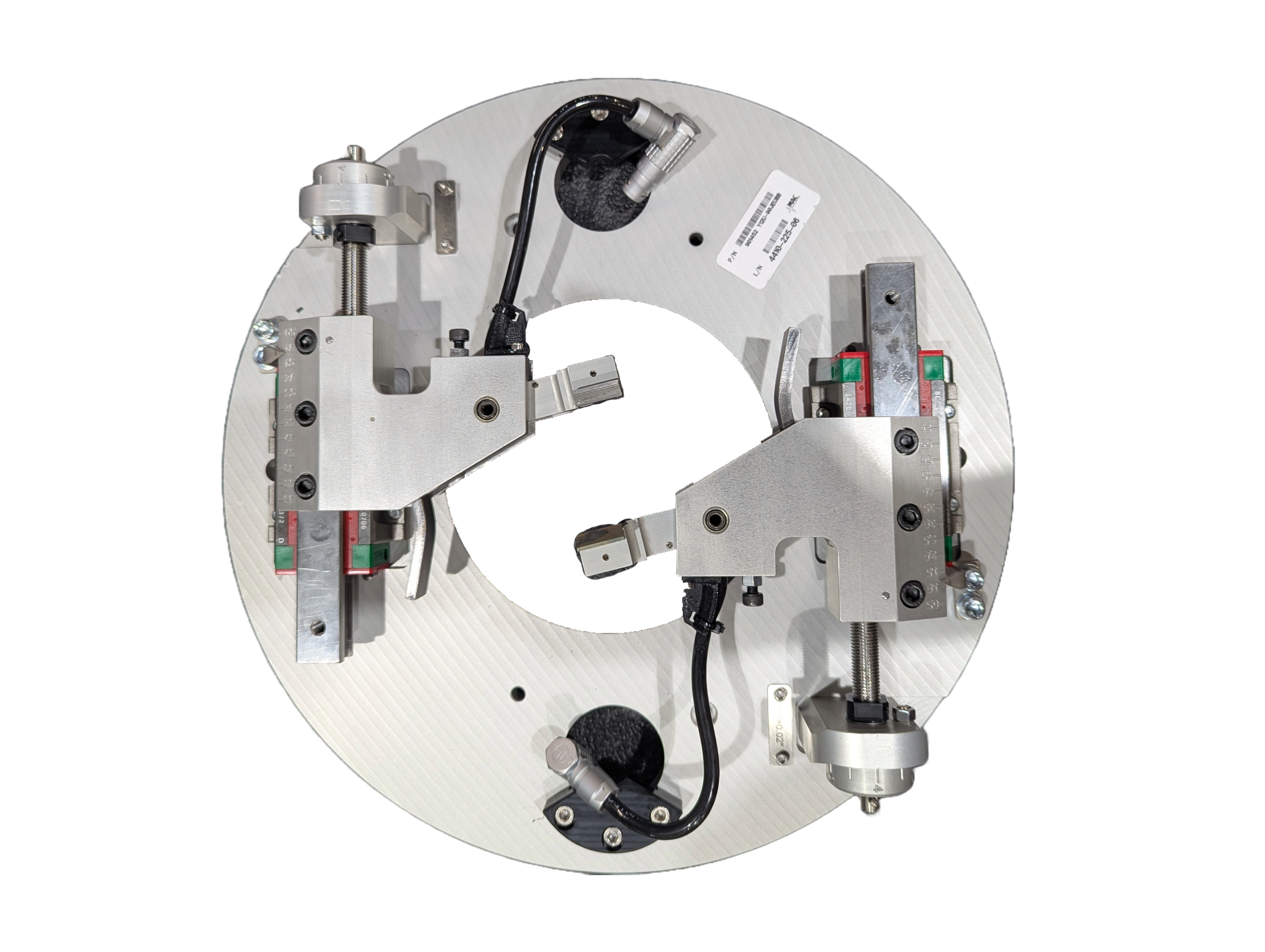

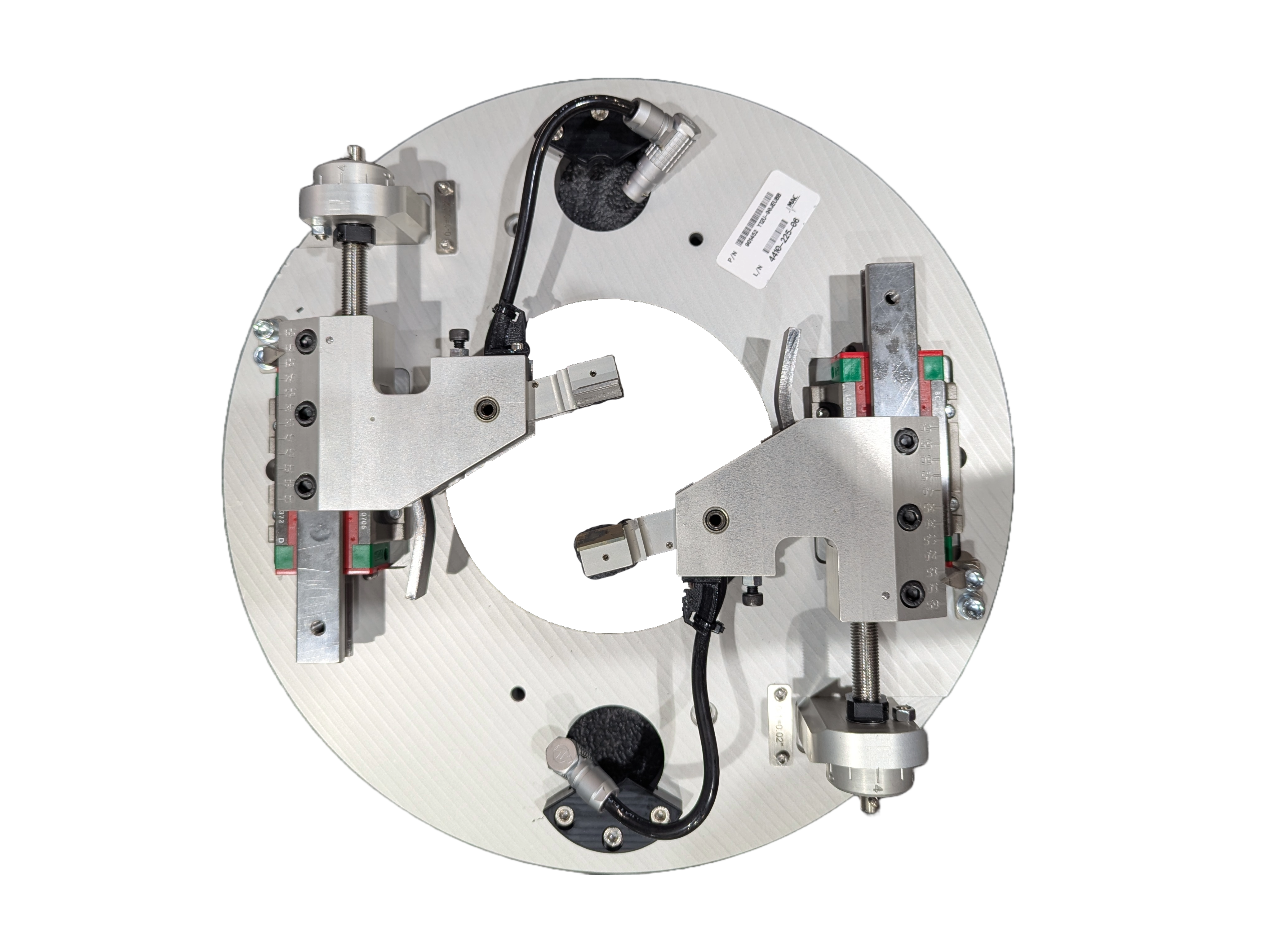

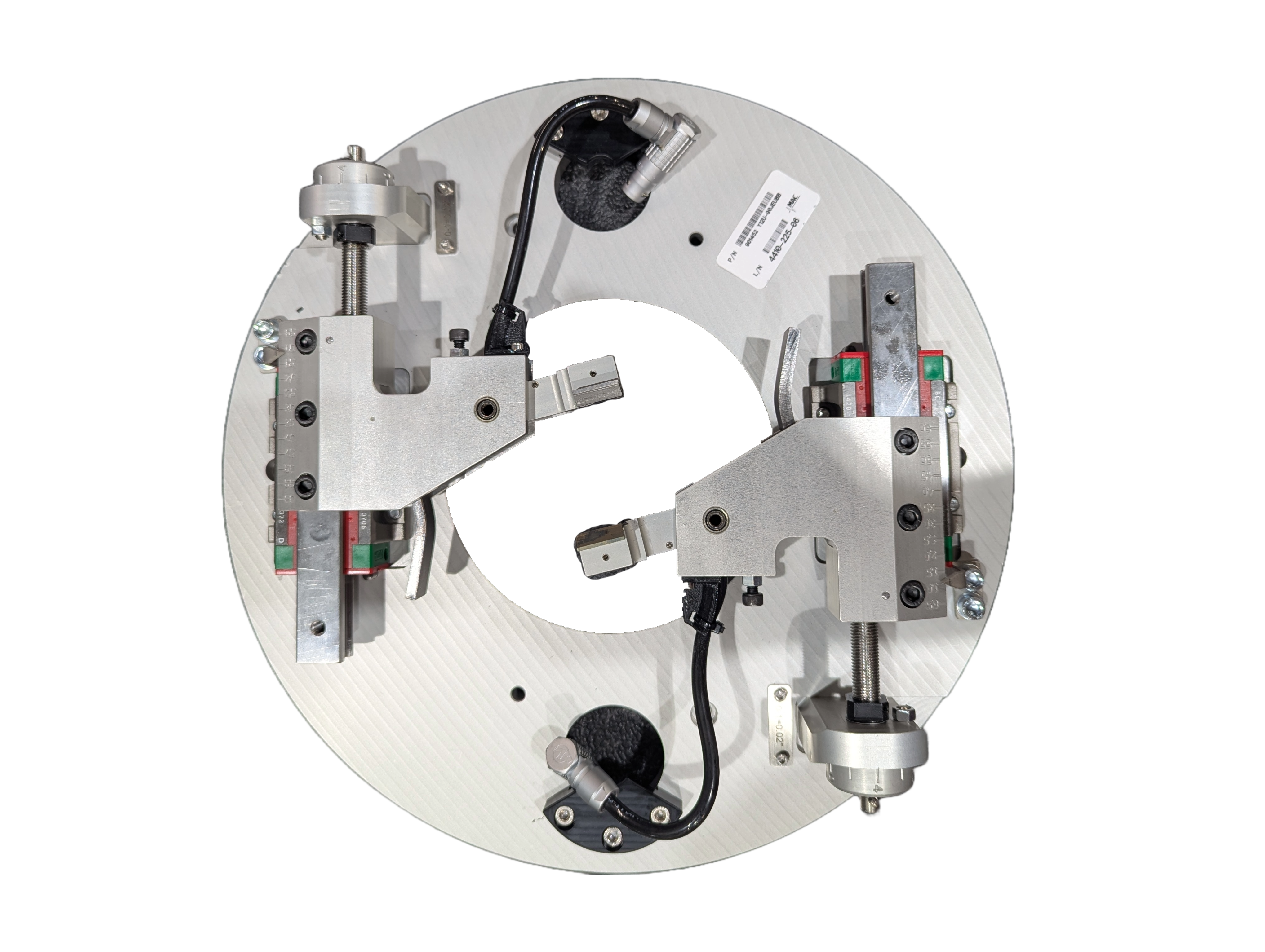

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

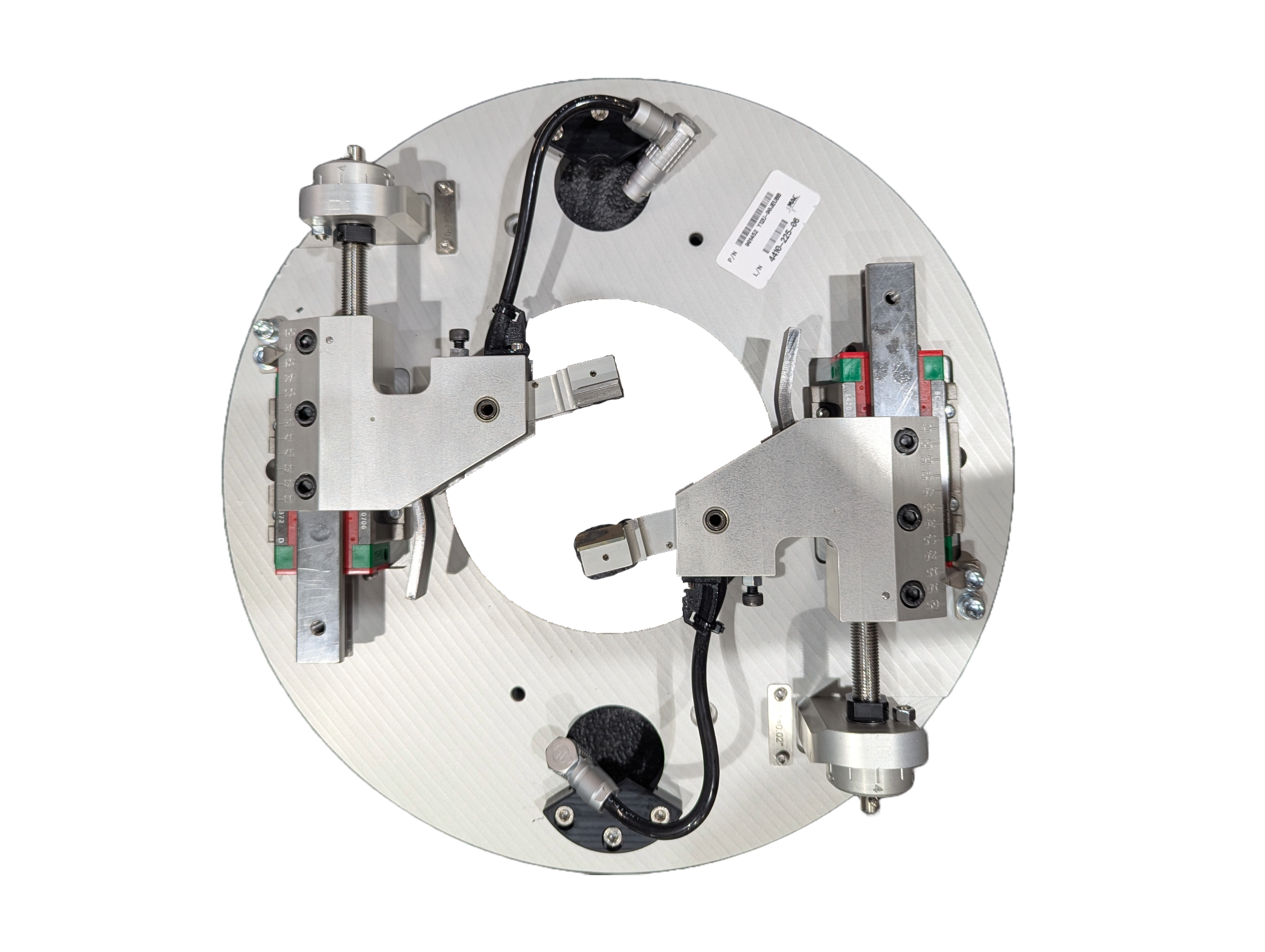

HEADPLATE ASSEMBLY, 10R4C-180MM

SKU: Y10A-180MBAU

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

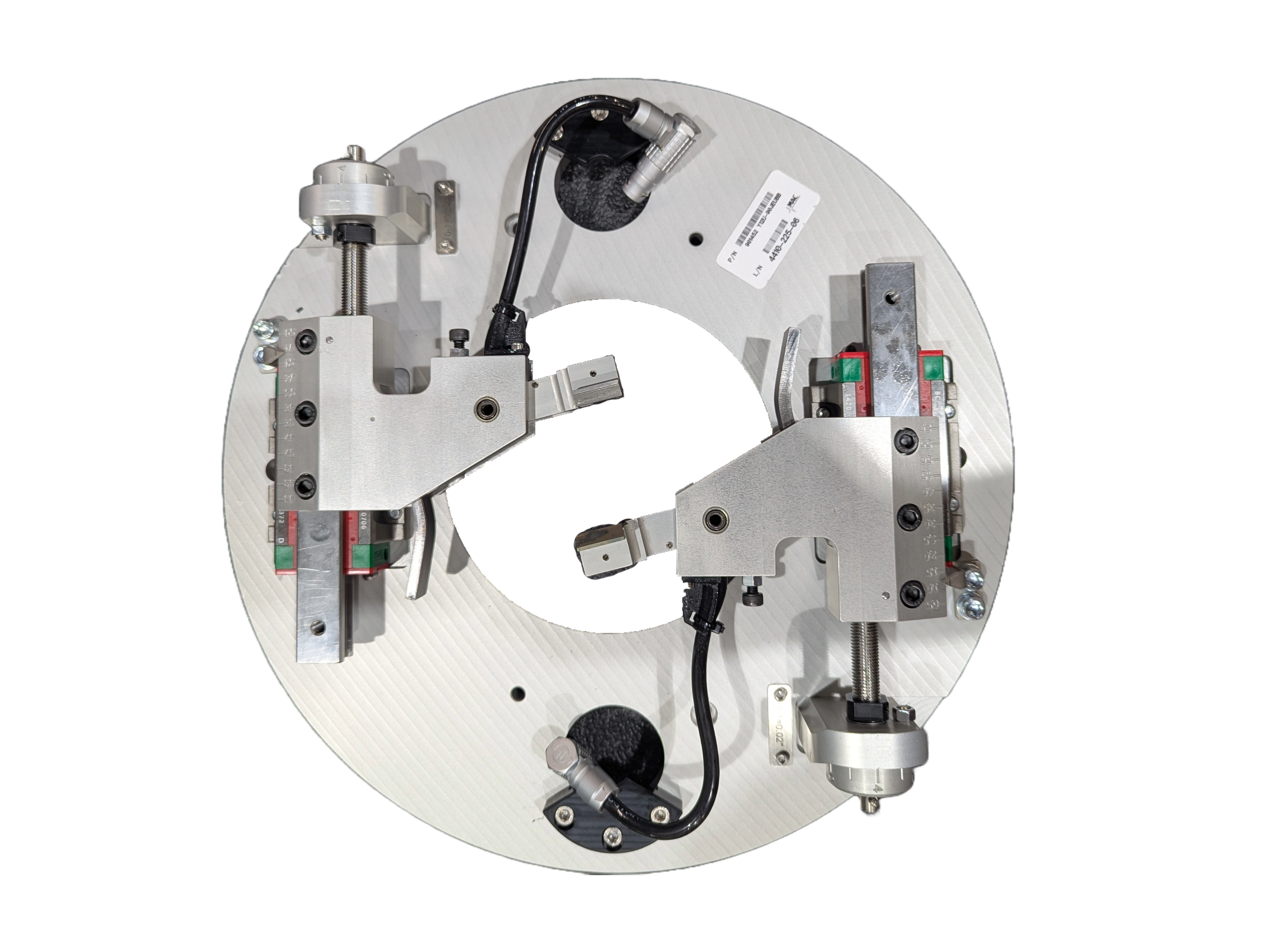

HEADPLATE ASSEMBLY, 9R4C

SKU: Y9A-750EBAG

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

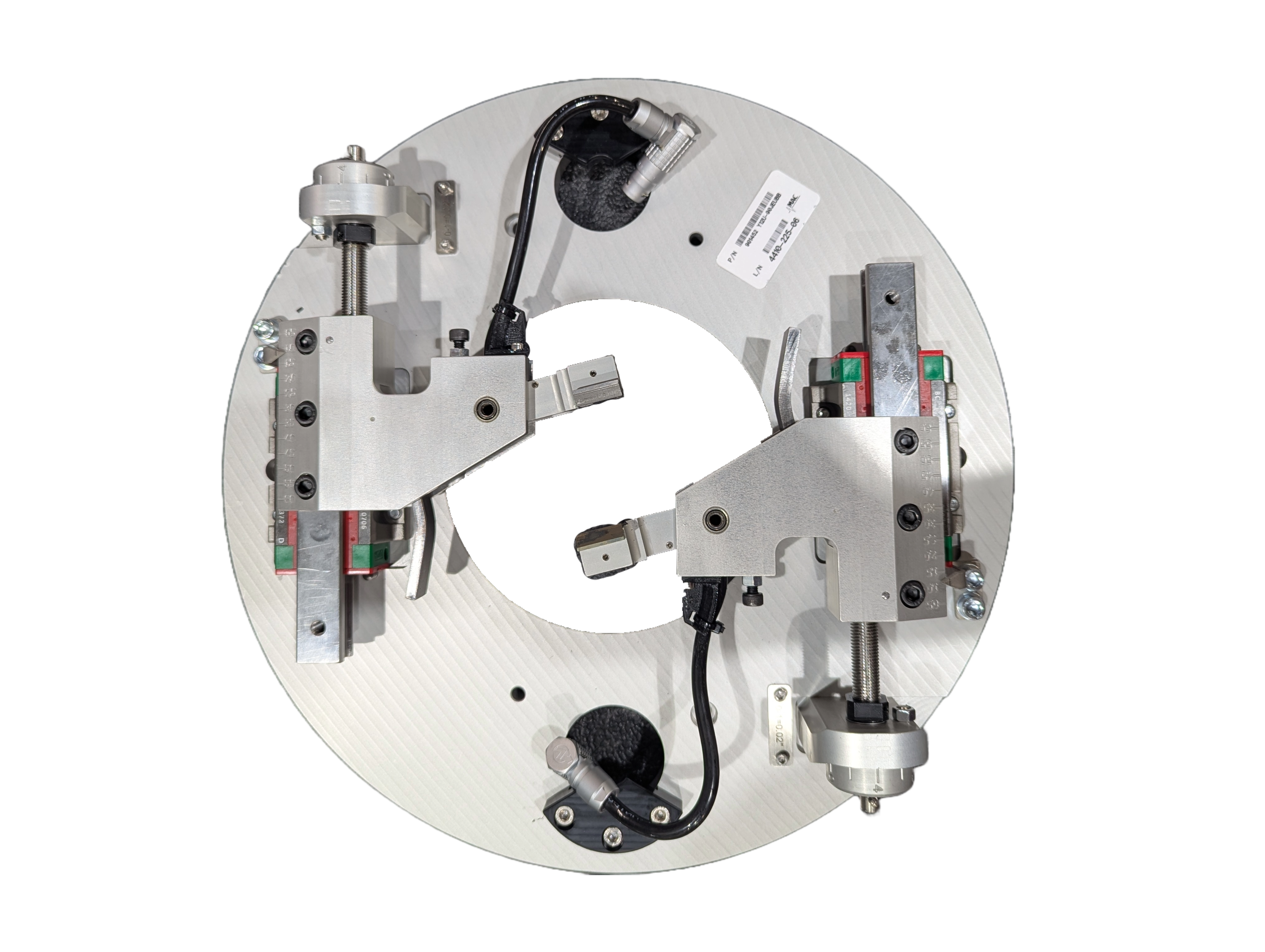

HEADPLATE ASSEMBLY, Y10U-150SA

SKU: Y10U-15SA

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

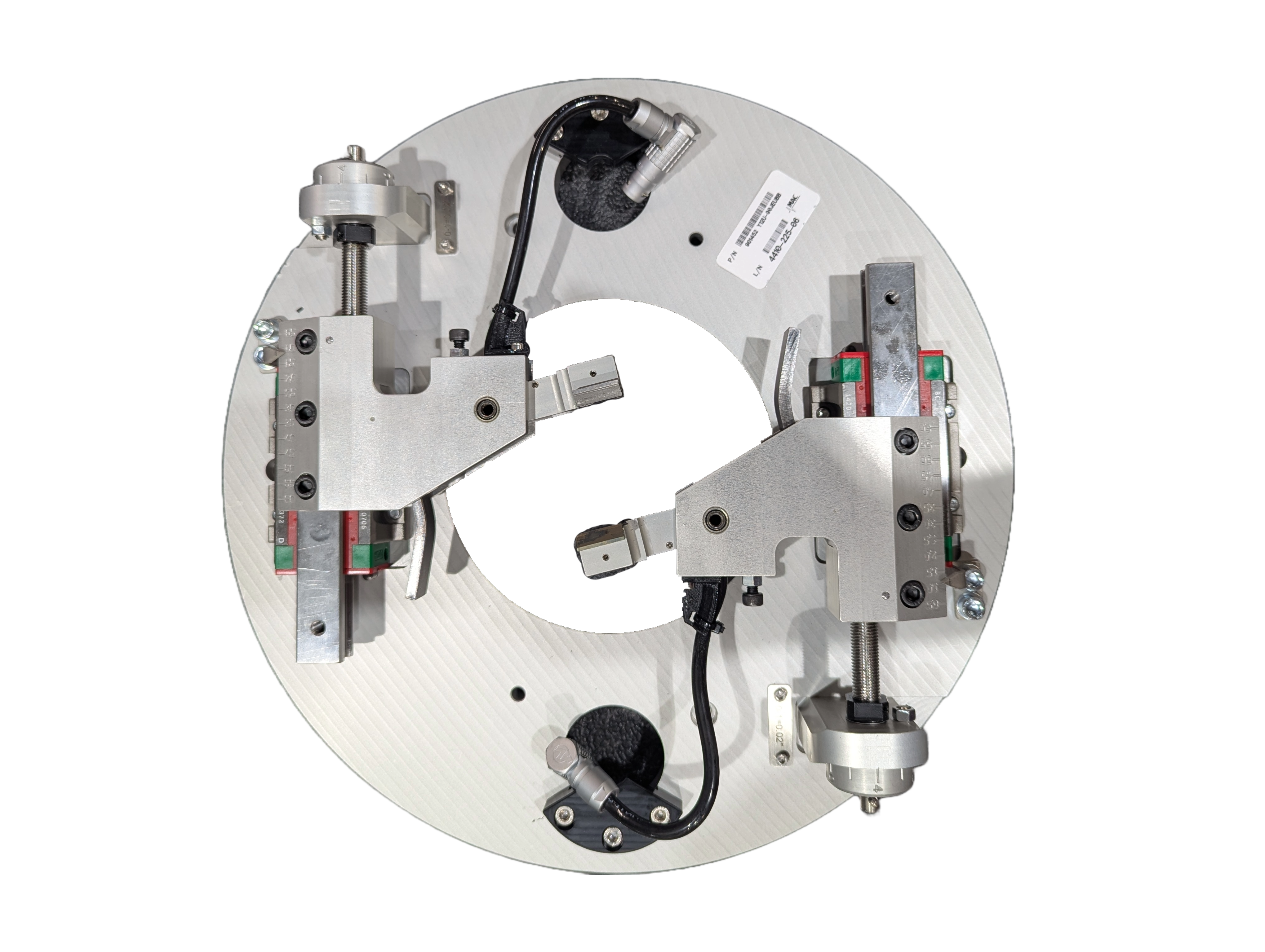

HEADPLATE, 12R3C-40MM ROTARY

SKU: Y12U-40NMBBA

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 12R3C-40MM ROTARY

SKU: Y12U-40NMBBH

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 12R3C-40MM ROTARY

SKU: Y12U-40NMZAY

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 12R4C-90MM ROTARY

SKU: Y12U-90JEUBB

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 12R6C-180MM ROTARY

SKU: Y12U-180MUBB

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1600 ROTOFLUX

SKU: Y1600-RFX

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM (8 SER) DUALDET

SKU: Y8A-550 A

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM (8 SERIES)

SKU: Y8A-550

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM (8 SERIES)

SKU: Y8S-550

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM (8 SERIES)

SKU: Y8S-559A

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM, 10R2C

SKU: Y9U-600EBAI

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM, 9R, 10R, 4C

SKU: Y9U-550EMH

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM, 9R, 9R2C

SKU: Y9U-550

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM, 9R, 9R2C

SKU: Y9U-550

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM, 9R, 9R2C

SKU: Y9U-600

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM, 9R2C, ABSOLUTE

SKU: Y9U-550EBAI

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.

HEADPLATE, 1800 RPM, 9R2C, ABSOLUTE

SKU: Y9U-550EBAI

Headplates provide stable monitoring solution for eddy current testing probes. They ensure proper alignment between the test equipment and the material under inspection, contributing to consistent and accurate results. Headplates are designed for durability and adaptability, suitable for a range of NDT applications, including both manual and automated systems.