OIL COUNTRY TUBULAR GOODS

Oil Country Tubular Goods (OCTG) are used in oil and gas production. As a rule, these include drill pipe, casing and tubing that are used both onshore and offshore. Producers of OCTG tube must meet the demands of individual client specifications, as well as API 5L & 5CT, ISO, EN and other standards.

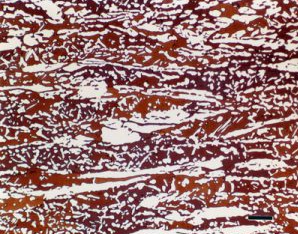

NODULARITY INSPECTION

As the use of nodular graphite iron material has expanded in recent years for cast automotive safety parts, ultrasonic velocity measurement is providing a reliable, industry accepted means of verifying material integrity.

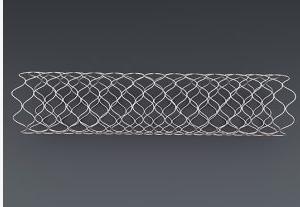

TESTING HIGH PERFORMANCE NITINOL WIRE

Magnetic Analysis Corporation has introduced an eddy current test for detecting cracks and inclusions in Nitinol wire. Surgical applications such as stents and heart valves, where the wire's ability to be deformed at one temperature during insertion, and then recover its original, undeformed shape when heated above its "transformation temperature" after exposure to typical body temperatures of 98.6°F (37°C), is essential.

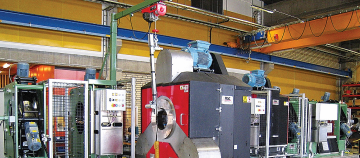

MULTI-TEST SYSTEM FOR AUTOMOTIVE SHOCK ABSORBER TUBING & OCTG

Magnetic Analysis Corp. has supplied a combined ultrasonic/eddy current test system to inspect cold drawn welded tube to be used in manufacturing shock absorbers at a new plant in Monterrey, Mexico, built by Prosankin, formerly known as A-4C-Sankin. The plant’s focus is production and sales of cold drawn tubes primarily for automotive use, although the test system is also designed to provide the future capability of meeting API 5CT testing requirement for oil country tubular goods (OCTG).

MEDICAL TUBE AND WIRE

As NDT techniques have expanded, so have the applications which now encompass many critical products that are being used where it is extremely difficult and expensive to replace or repair, or where failure can cause serious and life threatening consequences.

HEAT EXCHANGER TUBE

These types of tubes are commonly found in heat exchangers used in oil refineries and for other large chemical processes, power generation and many other high liability, high down time cost applications. Many of these situations are also high pressure applications.

FINNED TUBE

Metallic inclusions in copper tubing can be caused by two major sources. The first comes from the material itself which can contain residual impurities from continuous casting. The second, and major source of metallic inclusions in finned copper tubes, occurs during the manufacturing process. Inclusions that are the results of the manufacturing process can appear in the tube when the tool used to make the fins is breaking.

FERRITIC INCLUSIONS IN NON-FERRITIC TUBE, BAR AND WIRE

Inclusions are small particles or linear ferrite residuals that are usually considered to be undesirable. They may be spherical or elongated. They may originate from two major sources.

ECHOMAC® ULTRASONIC SYSTEMS FOR ERW TESTING

Magnetic Analysis Corp.’s line of Echomac® systems for testing ERW tube during production now includes Phased Array ultrasonic models as well as conventional ultrasonic systems.

ECCENTRICITY INSPECTION

Eccentricity, where the OD and ID of a tube are not concentric, is a problem that is most often created during extrusion of the tube from billet. Eccentricity in the finished product can mean wall thicknesses that don’t meet specifications, causing problems during further processing downstream. The Echomac® FD, 4 Channel is an ultrasonic equipment used for detecting eccentricity.

DETECTING SIGMA PHASE

Sigma Phase is a brittle, nonmagnetic phase of tetragonal structure occurring in many transition metal alloys. It is frequently encountered in high chromium stainless steels. The test consists of a two channel MultiMac® eddy current tester. One channel is used for the detection of typical defects, while the other absolute channel is used for finding Sigma Phase.