WELD LINE TEST

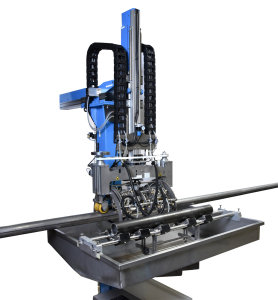

Echomac® Weld Line Ultrasonic Test System. Inspects tube weld quality during production.

Featuring new operating conveniences for inspecting tube weld zones on-line during continuous production, the system is designed to test for longitudinally oriented defects that are typical of the ERW welding process.

These systems typically include four channels, using both CW and CCW sound modes for detection of ID and OD longitudinal defects between 5% and 10% of wall thickness. Additional channels can be added, depending on the application.

- Includes MAC’s highly regarded Echomac® instrumentation with Echohunter® software.

- Test head incorporates transducer assemblies, with irrigated shoes, to provide constant coupling with the tube being tested.

- Test head is supported by a pillar mechanism that allows it to operate on the weld line for mill testing, or off line for easy calibration for a new tube size.

Weldline Tester with the Test Head conducting on-line production testing of a tube. A separate calibration tube is shown in the off-line position in the foreground.

- Operator can verify that transducers are correctly positioned by observing a monitor which shows a laser beam that must bisect the weld center.

- Convenient joy stick control allows transducer assemblies to be rotated to follow the weld, achieving continuous optimal testing over a weld position of 10:00 to 2:00 o’clock.

- Includes coupling alarm to alert for any loss of coupling between any transducer and the tube, caused by loss of water or improper alignment

- Spray marker downstream, automatically sprays paint onto the actual defect location to enable sorting of the cut tubes.

- Change out individual transducer shoes for size changes in 5 seconds using quick disconnect mechanism.

Other options for testing weld quality are also available from MAC. Our 90+ years’ experience in NDT and trained and experienced MAC people can help you to determine which test method should be used.

ECHOMAC® FD6

For Flaw Detection, Thickness & Dimensional Measurement in Tube & Bar

- Versatile Ultrasonic tester with superior performance and versatile, intuitive operation.

- For full inspection of tubes, pipes and bars, plate and weld.

- Operate on or off line.

- Upgrade and/or replace older ultrasonic testers.

- Use with rotary, spin-the-tube, squirter and bubbler installations.

ULTRASONIC TECHNOLOGY

High-speed Ultrasonic (UT) Systems enable a full volumetric examination of materials and are designed to detect surface, subsurface, internal and dimensional flaws.

This type of testing utilizes high-frequency sound waves that are transmitted throughout the material being tested in order to conduct a thorough inspection.

- Ultrasonic inspection can be used to detect surface flaws, such as cracks, seams, and internal flaws such as voids or inclusions of foreign material. It’s also used to measure wall thickness in tubes and diameters of bars.

- An ultrasonic wave is a mechanical vibration or pressure wave similar to audible sound, but with a much higher vibration frequency. For NDT purposes, the range is usually from 1MHz to 30MHz or higher.

- Depending on the test requirements, these waves can be highly directional and focused on a small spot or thin line, or limited to a very short duration.

- Two methods of UT are used for flaw detection – Shear and Compression Wave.

Close-Up of Weld Line Test Head during Inspection